Catalyst for one-step preparing cyclohexanone by hydrogenation of water phase phenol, and its preparation method

A technology of phase phenol and catalyst is applied in the field of one-step preparation of cyclohexanone by hydrogenation of aqueous phenol, and achieves the effects of simple separation, high activity and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0030] The metal-organic framework (MOF) used in the following examples can be prepared according to the following examples 1-4:

Embodiment 1

[0032] Cr(NO 3 ) 3 9H 2 O, HF and terephthalic acid were added to deionized water at a molar ratio of 1:1:1, and the aqueous solution was transferred to a polytetrafluoroethylene-lined hydrothermal reactor, and reacted at 220 °C for 8 h. Cool to room temperature at a cooling rate of 0.16°C / min and then filter to obtain a green powder. Then soak the powder in 95% by mass ethanol, place it at 80° C. for 24 hours, and finally vacuum-dry it at 150° C. for 10 hours to obtain an activated metal-organic framework (MOF). After testing, the MOF material has a very high comparison area (S BET ≈3000m 2 / g) and a large pore structure with a large number of Lewis acid sites (about 2000 μmol g -1 ), and has good thermal stability and good chemical stability.

Embodiment 2

[0034] Cr(NO 3 ) 3 9H 2 O, HF and terephthalic acid were added to deionized water at a molar ratio of 1:1:0.75, and the aqueous solution was transferred to a polytetrafluoroethylene-lined hydrothermal reactor, and reacted at 210°C for 9h. Cool to room temperature at a cooling rate of 0.2°C / min and then filter to obtain a green powder. Then soak the powder in 95% by mass ethanol, place it at 80° C. for 24 hours, and finally vacuum-dry it at 150° C. for 10 hours to obtain an activated metal-organic framework (MOF).

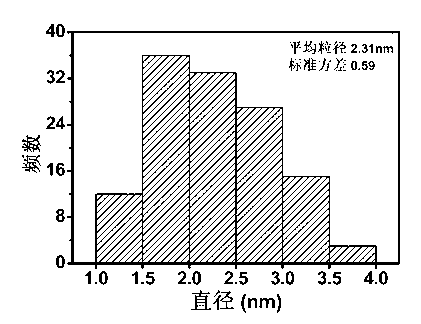

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com