Sewage source processing system and processing method

A treatment system and water treatment technology, applied in biological water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as high equipment requirements, high operation and maintenance costs, heat loss, etc. , to achieve the effect of overcoming the lack of flow drop, ensuring the quality of facility construction, and increasing the effective volume ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The preferred embodiment of the present invention will be described in detail below.

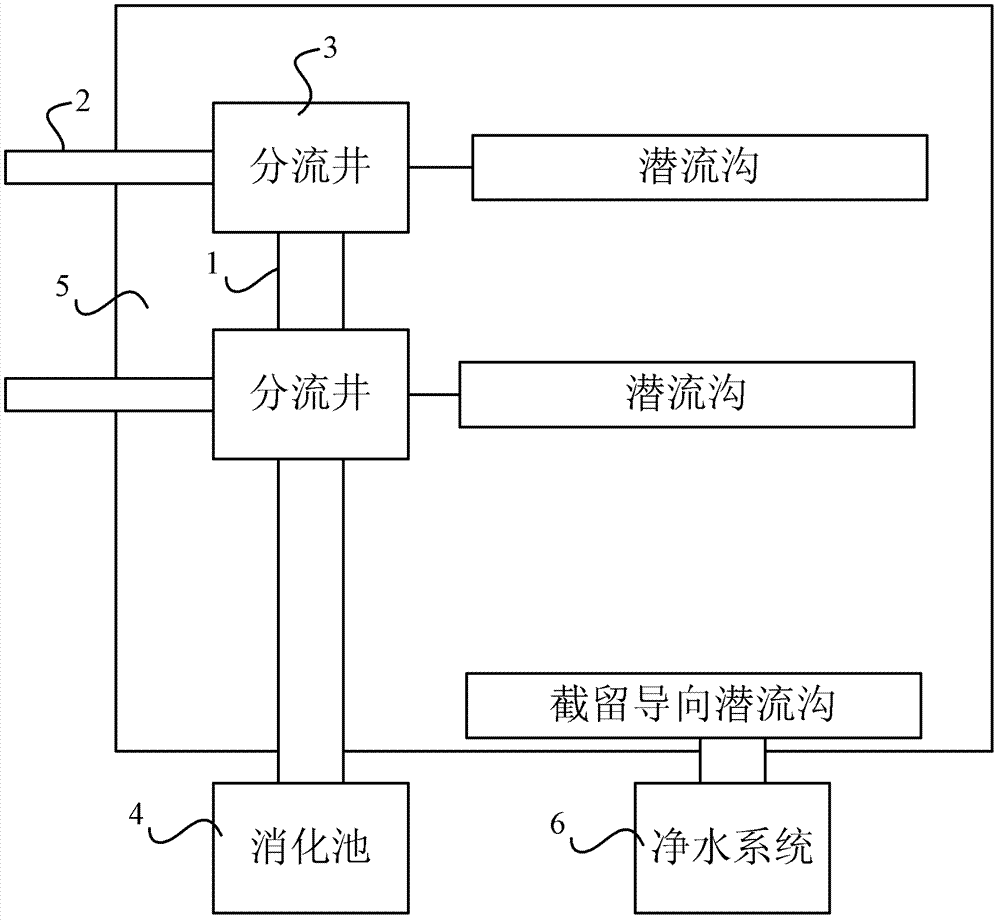

[0056] See figure 1 , The sewage source sewage treatment system of this embodiment includes sewage drainage trunk pipe 1, source sewage drainage branch pipe 2, diversion well 3, digestion tank 4, water treatment wetland 5 and water purification system 6.

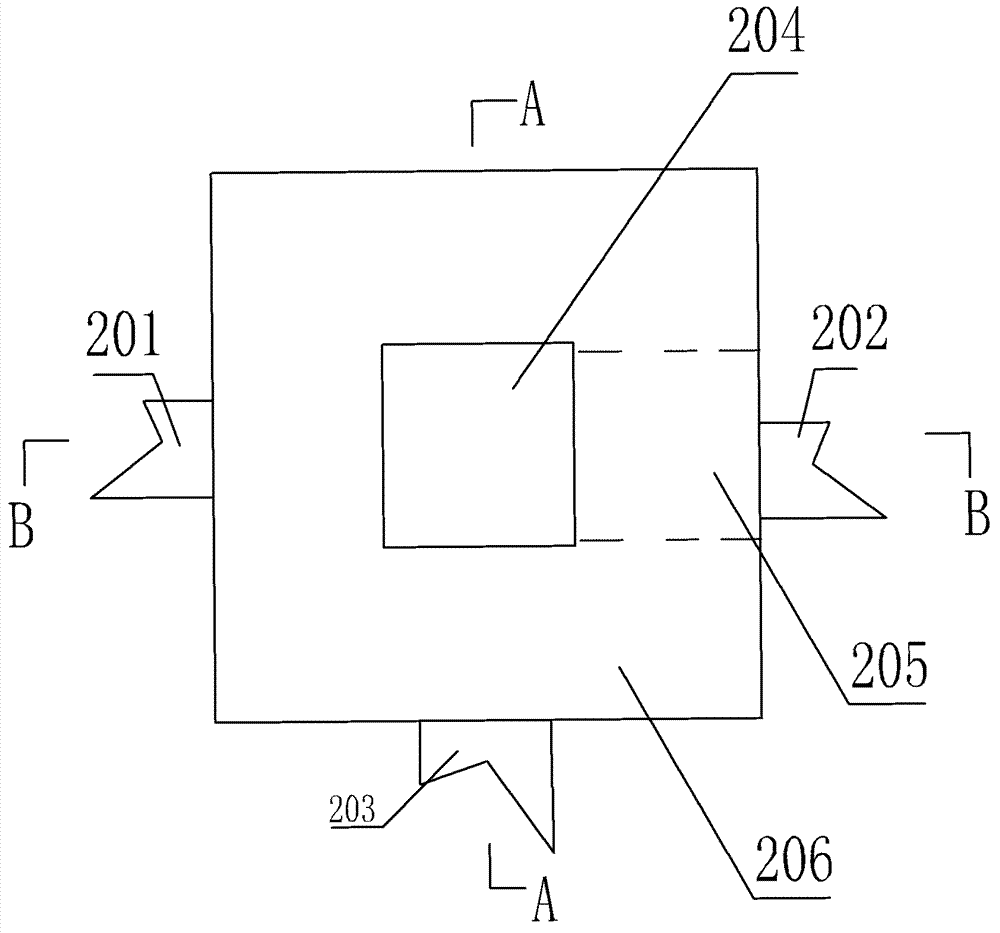

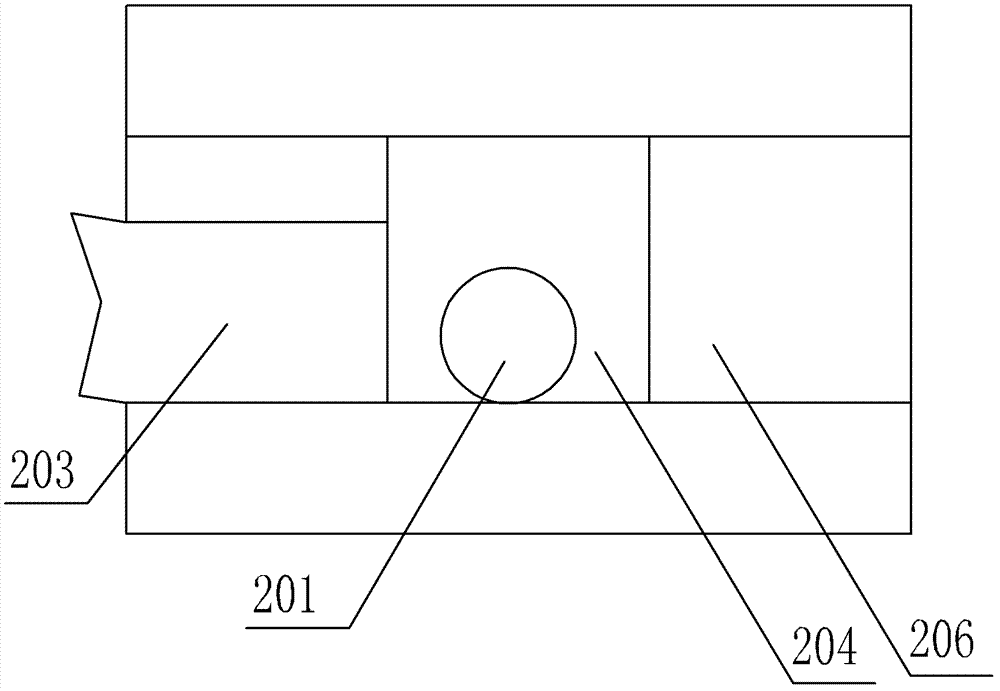

[0057] See figure 2 , 3 4. The diversion well includes a diversion well cavity 204 surrounded by a diversion well wall 206, the main body of the diversion well wall 206 is made of bricks, and sewage trunks are provided on both sides of the bottom of the diversion well wall 206 The inlet pipe interface 201, the main sewage discharge pipe interface 202, the active sewage inlet pipe port 203 and the overflow outlet 205 are arranged under the manhole cover 207 on the upper part of the shunt well wall 206, and the source sewage drainage branch pipe is connected to the shunt through the source sewage pipe port 203. The well cavity 204 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com