Synthesis method of titanium silicalite TS-1

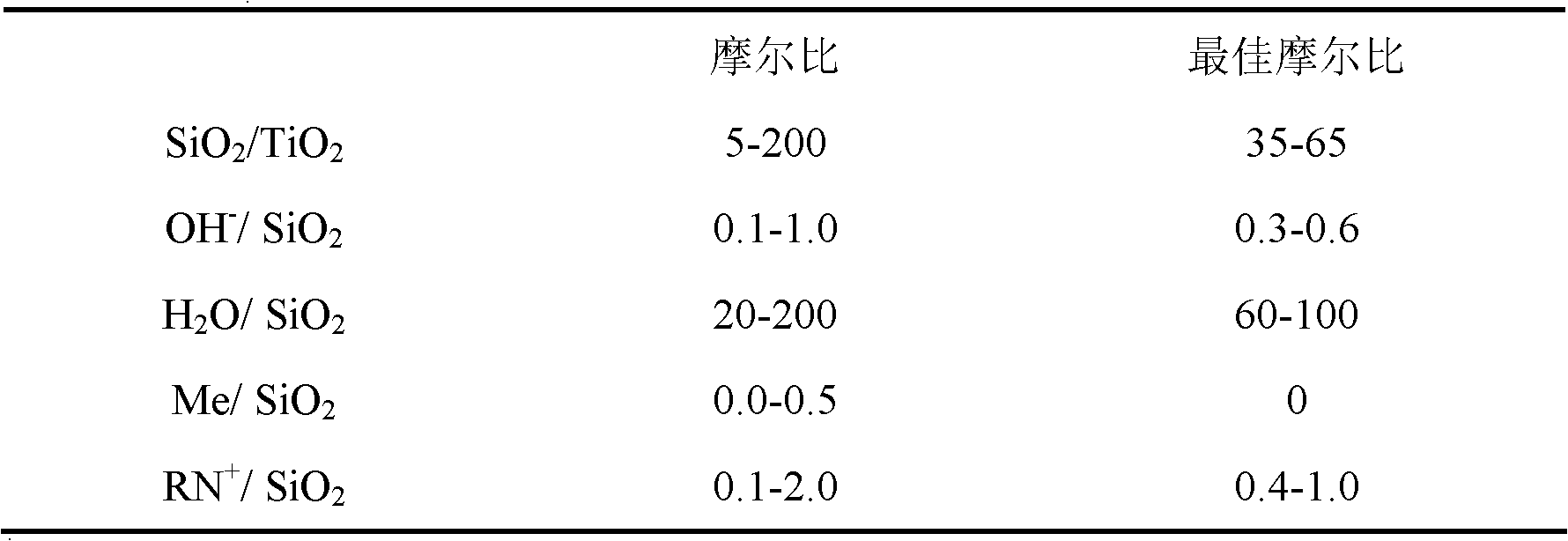

A titanium-silicon molecular sieve and a synthesis method technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of increasing the content of amorphous six-coordinate non-framework titanium, increasing the cost of TS-1 molecular sieve, poor effect of post-modification methods, etc. , to achieve the effect of inhibiting the formation of amorphous six-coordinate non-framework titanium, reducing acid centers, and relaxing purity requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0109] Get 220ml deionized water and join in 225g silica sol (20%wt), and add 5.3g sodium sulfate, after stirring for 10 minutes, add 20.4g tetrapropylammonium bromide in the glue solution, continue to stir for 20 minutes, obtained Raw silicon solution; mix tetrabutyl titanate and acetylacetone at a mass ratio of 1:0.9, and stir for 15 minutes to obtain raw titanium; take 14.7ml of the prepared raw titanium solution and add it to the raw silicon solution, and stir for 30 minutes Finally, add 54ml of n-butylamine, continue to stir for 15 minutes to obtain a uniform gel; then add the resulting gel to a 2L stainless steel reactor, and crystallize for 48 hours under autogenous pressure at 170°C; the product is filtered by conventional methods, Wash until neutral, dry at 110°C, and bake at 540°C for 6 hours to remove the templating agent to obtain molecular sieve sample B.

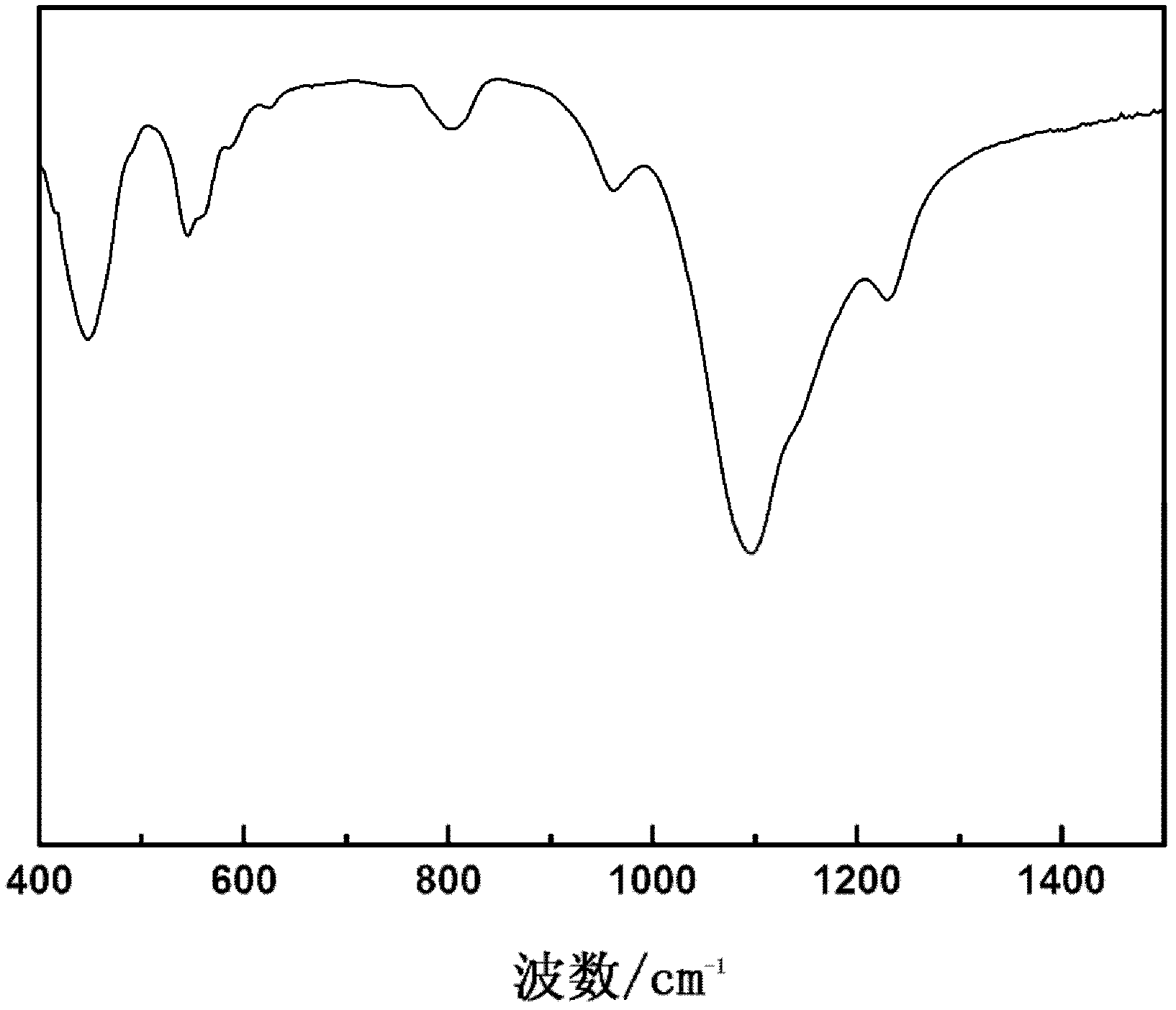

[0110] Its Fourier transform infrared spectrum and figure 1 Similarly, in the infrared spectrum at 960cm -...

Embodiment 2

[0112] Take 220ml of deionized water and add it to 225g of silica sol (20%wt), and after stirring for 10 minutes, add 20.4g of tetrapropylammonium bromide to the glue solution, and continue stirring for 20 minutes to obtain a raw silicon solution; Tetrabutyl ester and acetylacetone were mixed at a mass ratio of 1:0.9 and stirred for 15 minutes to obtain raw titanium; 14.7ml of the prepared raw titanium solution was added to the raw silicon solution, and after stirring for 30 minutes, 5.3g of sodium sulfate was added , stirred for 5 minutes, added 54ml of n-butylamine, and continued to stir for 10 minutes to obtain a uniform gel; then the resulting gel was added to a 2L stainless steel reactor, and crystallized for 48 hours under autogenous pressure and 170°C; the product was purified by conventional methods Filter, wash until neutral, dry at 110°C, and bake at 540°C for 6 hours to remove the template agent to obtain a molecular sieve sample. The propylene epoxidation propertie...

Embodiment 3

[0115] Repeat embodiment 1, but wherein the add-on of sodium sulfate becomes 10.6g, 2.65g, 0.53g. That is, c=0.2, 0.05, 0.01, then molecular sieve samples C, D, E are obtained in sequence.

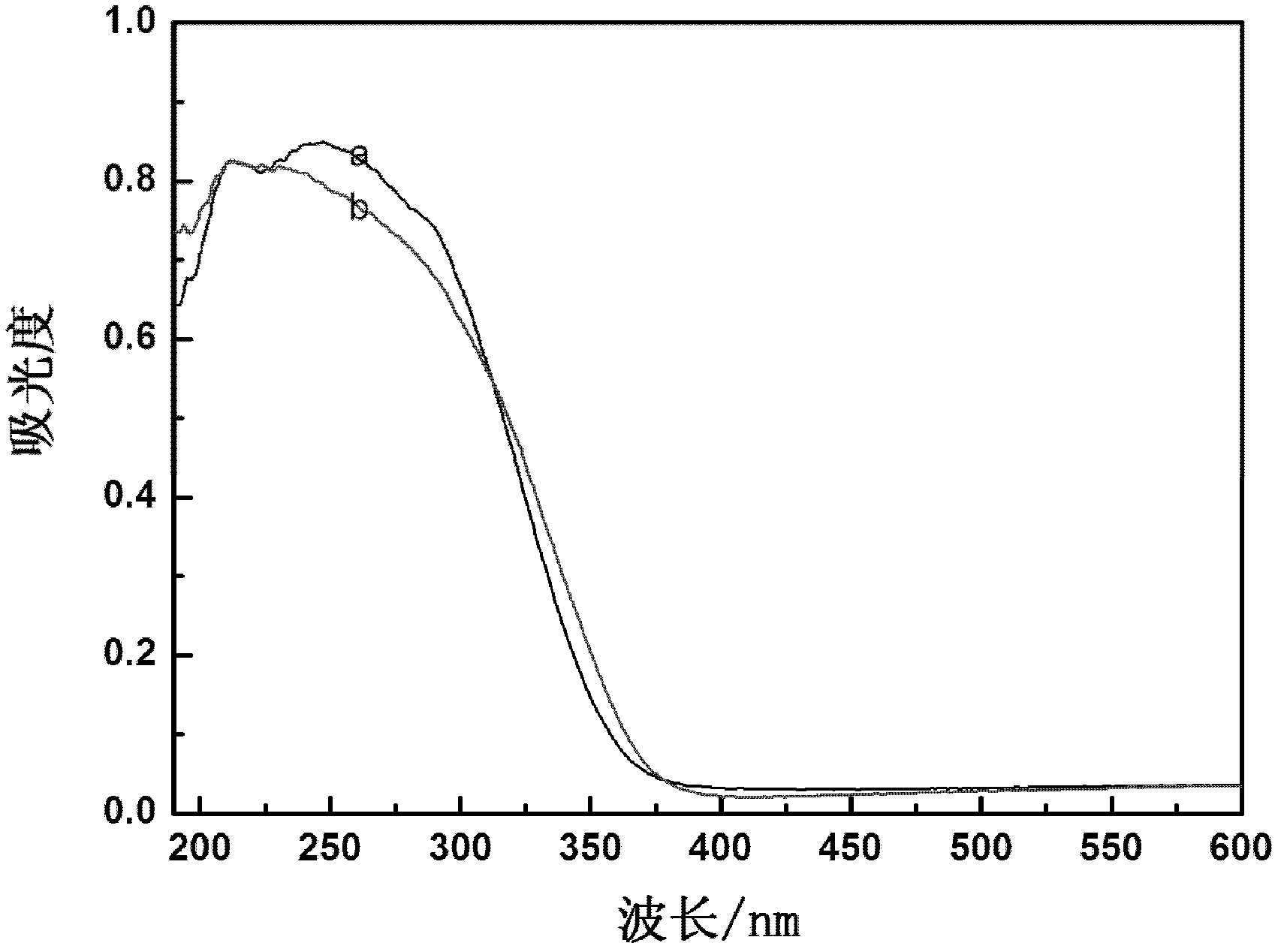

[0116] Its Fourier transform infrared spectrum is consistent with figure 1 Similarly, the UV-Vis spectrum and figure 2 (b) Similarly, the amorphous hexacoordinated non-skeleton content is significantly reduced. There is no absorption band of anatase at 330nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com