Phosphogypsum purification and neutralization apparatus

A purification device and phosphogypsum technology, which is applied in the field of purification and neutralization devices, can solve the problems of increasing the storage pressure of slag yards, environmental pollution, and difficult recycling of phosphogypsum, so as to achieve great economic benefits, reduce environmental pollution, and prolong storage The effect of years

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

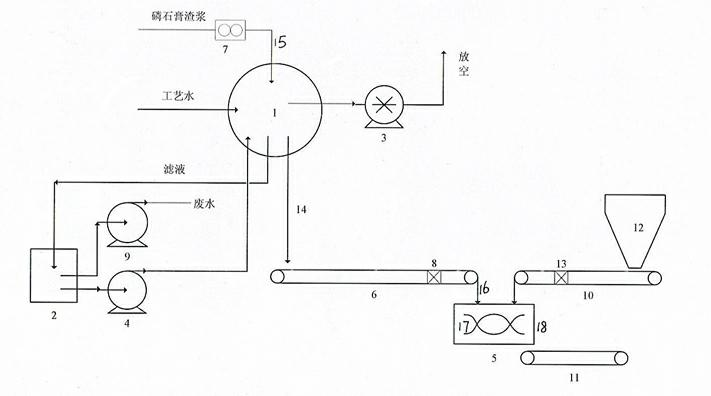

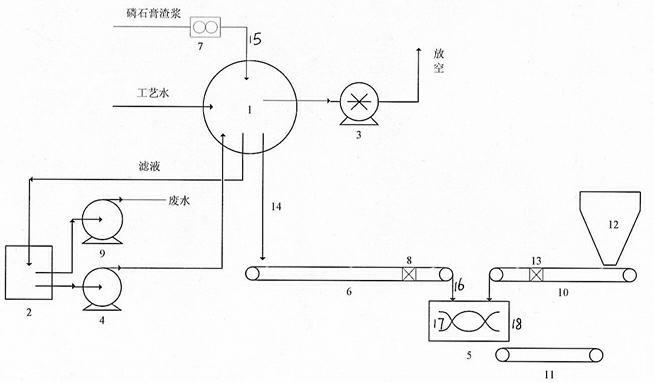

[0018] A certain factory adopts the present invention, and the device is shown in the accompanying drawings,

[0019] The purification device consists of a phosphogypsum feed line 15, a turntable filter 1, a washing circulation tank 2, a vacuum pump 3, a waste water delivery pump 9, a filter cloth regeneration washing pump 4, and a feeding chute 14. The filter 1 is matched with the vacuum pump 3, and the filter The machine 1 is connected with the filter cloth regeneration washing pump and the waste water conveying pump 9 respectively through the washing circulating water tank 2, and the filter 1 is provided with a feeding chute 14, and the feeding chute 14 is connected with the phosphogypsum raw material conveying belt 6;

[0020] The neutralization device consists of a feed chute 16, a driving device 17, a neutralization mixing agitator 5 and a cylinder 18. The neutralization mixing agitator 5 is connected to the lime silo 12 through a lime conveying belt 10, and the phosphogy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com