Method for producing cementation healing fussure stone

A production method and stone technology, which is applied in the field of stone and artificial synthetic stone processing, can solve the problems of cracked blocks that cannot be processed and utilized, and waste of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

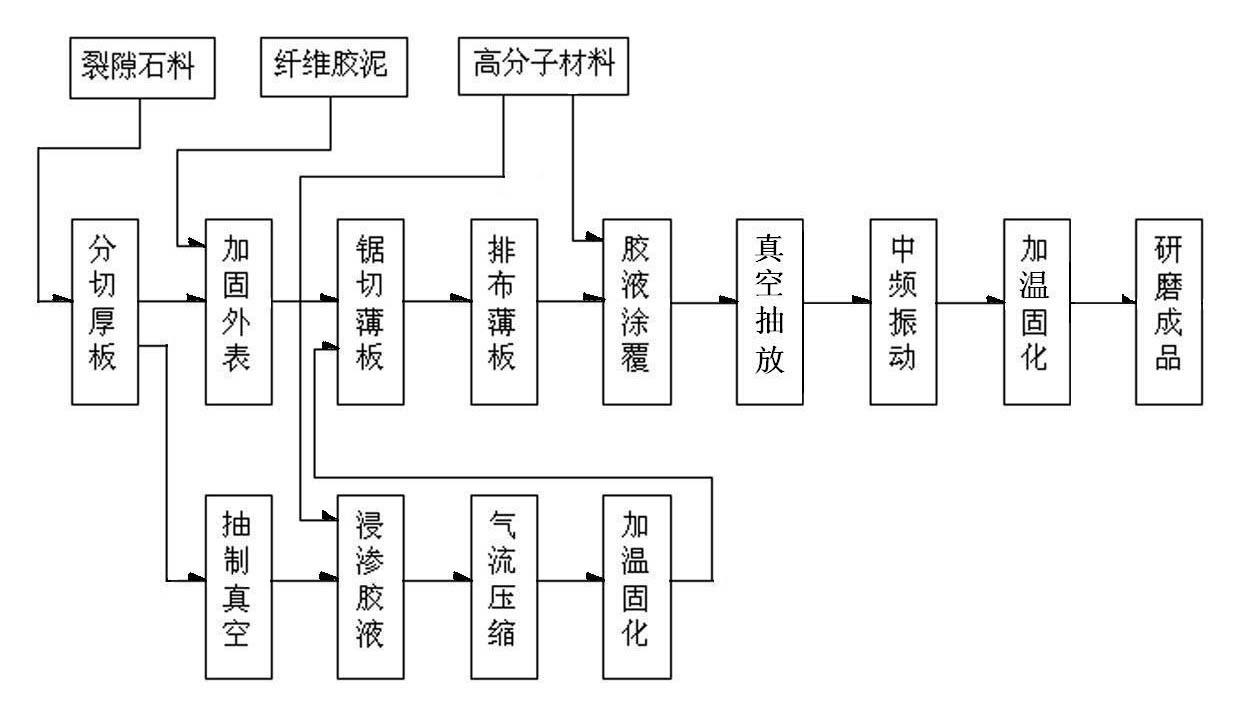

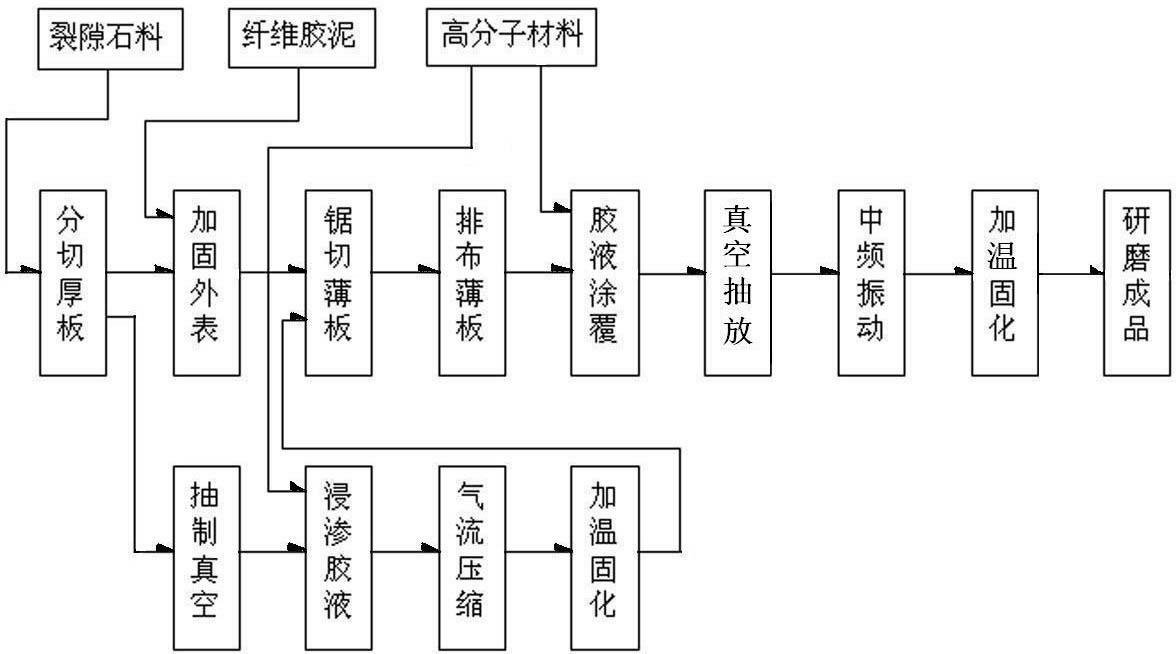

Method used

Image

Examples

Embodiment 1

[0024]Using Nailong marble blocks in Wutai County, Shanxi Province as cracked stone materials, it is suitable for the production of decorative tiles with a thickness of 10mm and countertops with a thickness of 30mm for indoor use. The steps of the production process are as follows:

[0025] (1) Cutting the thick board, using a single saw to trim the edge and cut the thick board of this siliceous marble, and cut it into a thick board with a thickness of 830mm, and the length and width depend on the block;

[0026] (2) For surface reinforcement, firstly, unsaturated polyester resin, methyl ethyl ketone peroxide, 800-mesh calcium carbonate powder, and glass fiber are prepared into the first component in parts by mass of 10:0.3:50:10, and then 0.1 The cobalt accelerator of mass parts replaces methyl ethyl ketone peroxide, and the mass parts of other raw materials remain unchanged to prepare the second component. Finally, the two components are mixed according to the mass ratio of 1...

Embodiment 2

[0036] Dunhuang jade (silicon jade) from Gansu is used for the processing of light decorative tiles, because it is quartz jade with a quartz content of 85%, especially the primary cracks and secondary cracks in white and red blocks are serious. According to the processing method of conventional natural stone slabs, its finished product rate is less than 20%, so it is impossible to make it form a production scale and occupy the building decoration material market, and the production of this method can overcome the above-mentioned problems. The specific process steps are:

[0037] (1) To cut the thick plate, use a circular saw with a diameter of 350cm and a special cutter head to trim the edge first, and then cut it into a thick plate with a thickness of 300mm. The length and width depend on the block;

[0038] (2) For surface reinforcement, firstly, unsaturated polyester resin, methyl ethyl ketone peroxide, 100-mesh calcium carbonate powder, and nylon fiber are prepared into the...

Embodiment 3

[0048] The grey-green Yutaiyu from Inner Mongolia and the associated minerals from Shanxi obsidian and perlite are used for the processing of railings, craft decorations and thin plates, so that these precious stones with serious cracks that are difficult to have a high yield rate after external reinforcement are converted and utilized. , the process steps of its production are:

[0049] (1) Cutting the thick board, using a single saw to cut the stone into a thick board with a thickness of 100mm, and the length and width depend on the block;

[0050] (2) For external reinforcement, first, unsaturated polyester resin, methyl ethyl ketone peroxide, 300 mesh calcium carbonate powder, and glass fiber are prepared into the first component in parts by mass of 10:0.2:30:20, and then 0.05 The cobalt accelerator of the mass fraction replaces the methyl ethyl ketone peroxide, and the mass fraction of the remaining raw materials remains unchanged to prepare the second component. Finally,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com