Method for synthesizing acetic acid through carbonylation

A technology of chemical synthesis and acetic acid, which is applied in the direction of chemical instruments and methods, carbon monoxide reaction to prepare carboxylic acid, organic compound/hydride/coordination complex catalyst, etc., which can solve the problems of increased energy consumption for separation, difficulty in continuous operation, and easy volatility, etc. problems, to achieve the effects of slowing down adverse effects, improving reactivity, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

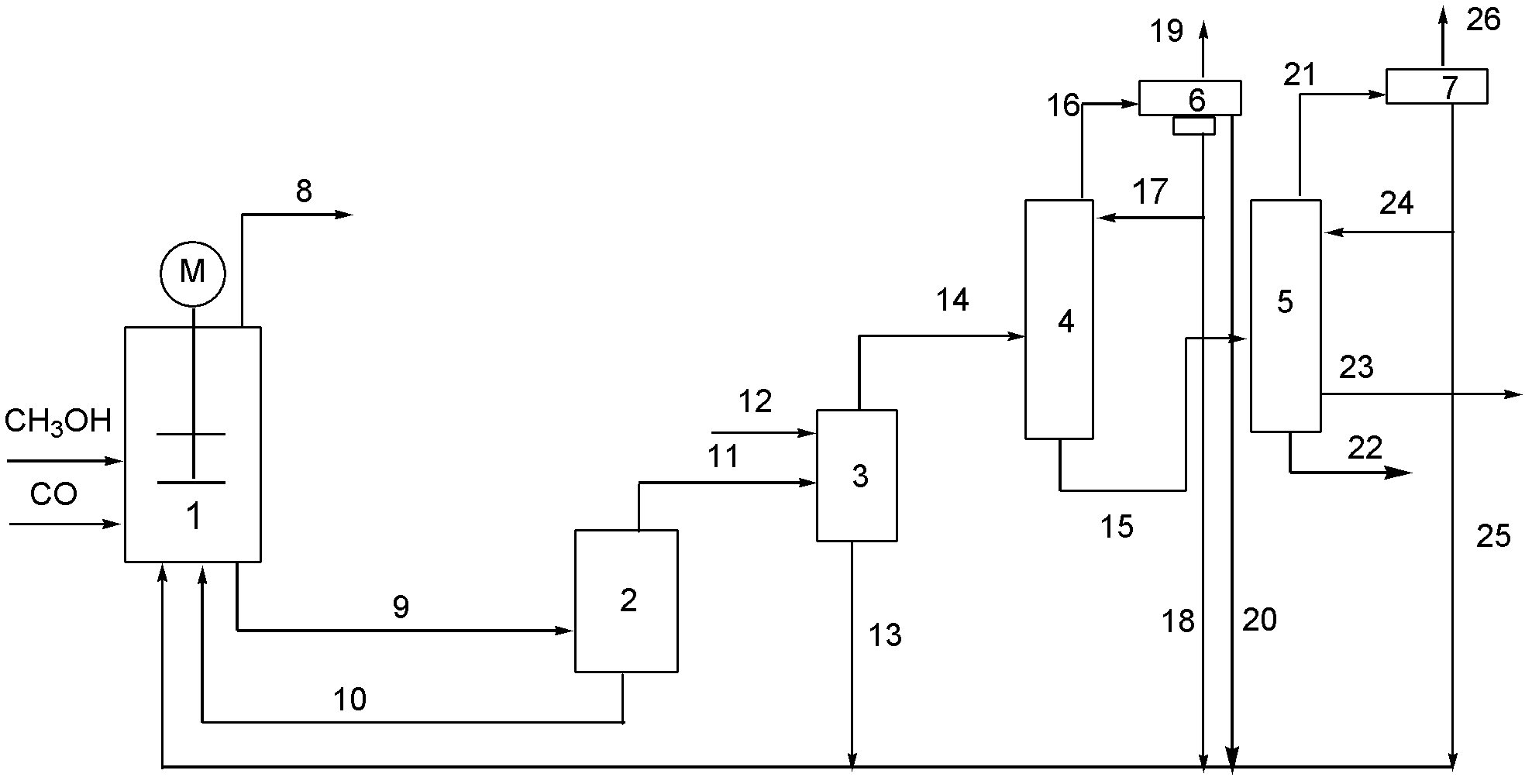

Method used

Image

Examples

Embodiment 1

[0039] Add rhodium iodide (rhodium content 20wt%) 437mg in the zirconium material autoclave that pressure gauge is housed in 200ml, add triphenylphosphine oxide and ruthenium acetate precursor, make rhodium catalyst: triphenylphosphine oxide: the mol ratio of ruthenium 1:5:2, methyl iodide 15g, distilled water 7.5g, methyl acetate 25g, lithium iodide 7.5g, the rest is acetic acid solvent, the total weight is 125 grams, keep the reaction temperature 190 ℃, the reaction pressure 30bar, the average reaction The STY is 8.1 mol / lh, and the STY at 3% ester concentration and 1.7% water content is 7.0 mol / lh, and the content of propionic acid is 200ppm after the reaction. After the reaction, the reaction solution was heated continuously for 12 hours under simulated flash evaporation conditions, and the precipitation rate of the rhodium catalyst was 10%.

Embodiment 2

[0041] Add rhodium iodide (rhodium content 20wt%) 624mg in the zirconium material autoclave that pressure gauge is housed in 200ml, add triphenylphosphine oxide and ruthenium acetate precursor, make rhodium catalyst: triphenylphosphine oxide: the mol ratio of ruthenium 1:5:2, methyl iodide 15g, distilled water 7.5g, methyl acetate 25g, lithium iodide 7.5g, the rest is acetic acid solvent, the total weight is 125 grams, keep the reaction temperature 190 ℃, the reaction pressure 30bar, the average reaction The STY is 10.1 mol / lh, and the STY at 3% ester concentration and 1.7% water content is 7.6 mol / lh, and the content of propionic acid is 205ppm after the reaction. The reaction solution after the reaction was heated continuously for 12 hours under simulated flash evaporation conditions, and the precipitation rate of the rhodium catalyst was 12%.

Embodiment 3

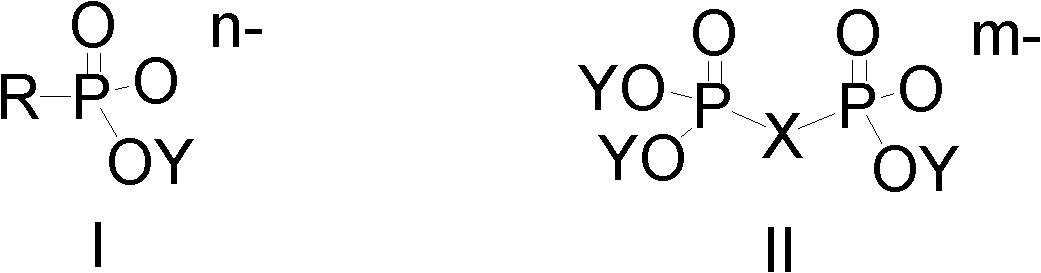

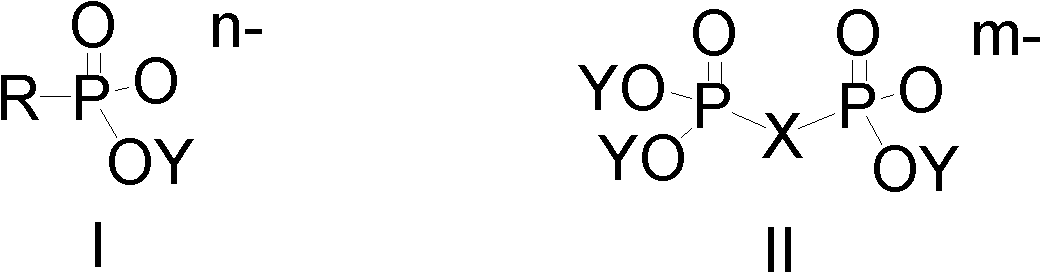

[0043] Add rhodium iodide (rhodium content 20wt%) 437mg in the zirconium material autoclave that pressure gauge is housed in 200ml, add dibutyl lithium phosphonate and iridium acetate precursor, make rhodium catalyst: dibutyl lithium phosphonate: iridium The molar ratio is 1:5:2, methyl iodide 15g, distilled water 7.5g, methyl acetate 25g, lithium iodide 7.5g, all the other are acetic acid solvents, total weight is 125 grams, keep reaction temperature 190 ℃, reaction pressure 30bar, reaction The average STY is 8.5mol / lh, and the STY under 3% ester concentration and 1.7% water content is 7.1mol / lh, and the content of propionic acid measured after the reaction is 200ppm. After the reaction, the reaction solution was heated continuously for 12 hours under simulated flash evaporation conditions, and the precipitation rate of the rhodium catalyst was 25%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com