Halogen-free flame retarding cross-linked polyethylene and preparation method thereof

A technology of crosslinked polyethylene and polyethylene, applied in the field of flame retardant polyethylene, can solve the problems of easy agglomeration of flame retardants, poor mechanical properties, large addition amount, etc., and achieve good impact resistance and antistatic performance, and good surface The effect of reducing quality and smoke production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

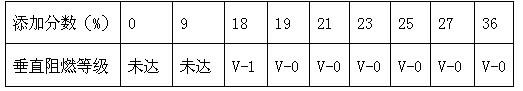

Embodiment 1

[0035] Example 1: Weigh 10.1kg of cross-linked polyethylene, 60.7kg of polyethylene, 18kg of high-efficiency nitrogen-phosphorus halogen-free flame retardant EPFR-100D, 4.9kg of toughening agent POE, and antistatic agent octadecyl dimethyl hydroxyethyl Base quaternary ammonium nitrate 0.3kg and filler talc powder 6.0kg, put them in a high mixer and mix them evenly, then extrude the mixed raw materials in a vacuum vented parallel co-rotating twin-screw extruder at 140-190°C, Water-cooled and pelletized to obtain a halogen-free flame-retardant cross-linked polyethylene material.

Embodiment 2

[0036] Example 2: Weigh 9.0kg of cross-linked polyethylene, 53.9kg of polyethylene, 27kg of high-efficiency nitrogen-phosphorus halogen-free flame retardant EPFR-100D, 4.4kg of toughening agent POE, and antistatic agent octadecyl dimethyl hydroxyethyl Base quaternary ammonium nitrate 0.3kg and filler talc powder 5.4kg, mix them evenly in a high mixer, and then extrude the mixed raw materials in a vacuum vented parallel twin-screw extruder at 140-190°C, water-cooled Diced.

Embodiment 3

[0037] Example 3: Weigh 7.7kg of cross-linked polyethylene, 47.5kg of polyethylene, 36kg of high-efficiency nitrogen-phosphorus halogen-free flame retardant EPFR-100D, 3.5kg of toughening agent POE, and antistatic agent octadecyl dimethyl hydroxyethyl Base quaternary ammonium nitrate 0.4kg and filler talc powder 4.9kg, mix uniformly in a high mixer, and then extrude the mixed raw materials in a vacuum vented parallel twin-screw extruder at 140-150°C, water-cooled Diced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com