PVC high-weatherability imitation-wood crust foaming material

A technology of skin foaming and weather resistance, applied in the field of foamed wood-plastic materials, can solve the problems of affecting processing and mechanical properties, loss of strength, thermal instability of molecular structure, etc., so as to reduce thermal instability and reduce the use of wood. , the effect of environmental protection

Inactive Publication Date: 2012-01-18

ANHUI GUANGDE JINPENG NEW MATERIAL MFG

View PDF1 Cites 29 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, as far as the use of wood is concerned, my country is a country with a low forest coverage rate. A large number of wood fiber materials such as wood powder and bamboo powder are used, which is a great damage to the ecological environment, and the thermal stability of wood powder and bamboo powder wood fibers Poor performance, easy to burn and carbonize in the case of high temperature or open flame, which poses a huge safety hazard in the process of production and use

[0004] As far as the polyvinyl chloride plastic used is concerned, polyvinyl chloride is an amorphous high polymer. Due to the instability of the molecular structure to heat, it has poor weather resistance. During processing, use and storage, it is exposed to light, heat, Oxygen, heavy metal ions, etc. will cause molecular chain chain reaction degradation, and eventually make it change color and age and lose strength, affecting its processing and mechanical properties

[0005] As far as wood-plastic foam materials are concerned, wood-plastic foam materials have the advantages of low density, light weight, and low cost. However, existing foam products generally have low hardness, insufficient toughness, rough surface, poor weather resistance, and production problems. poor security issues

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

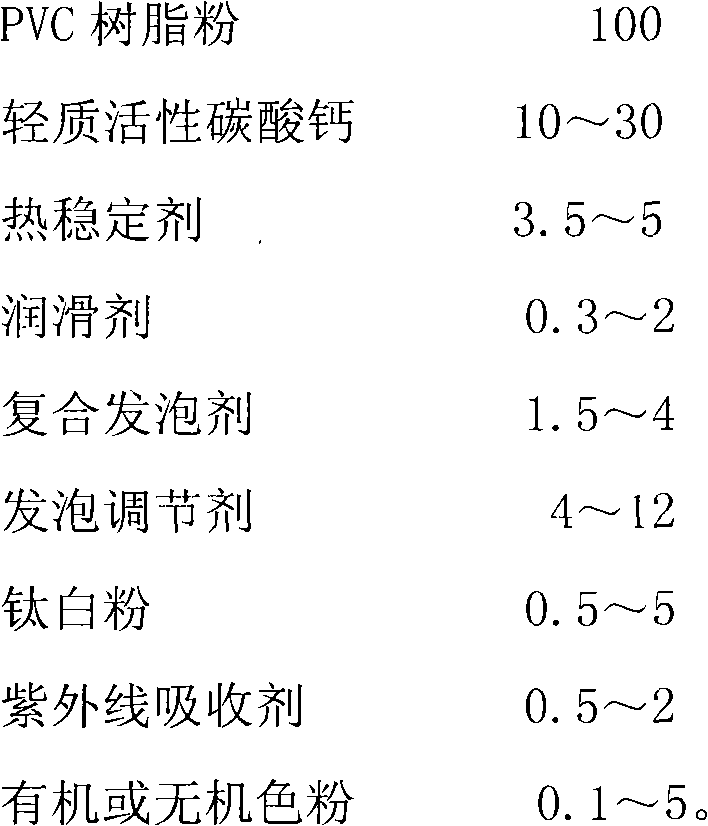

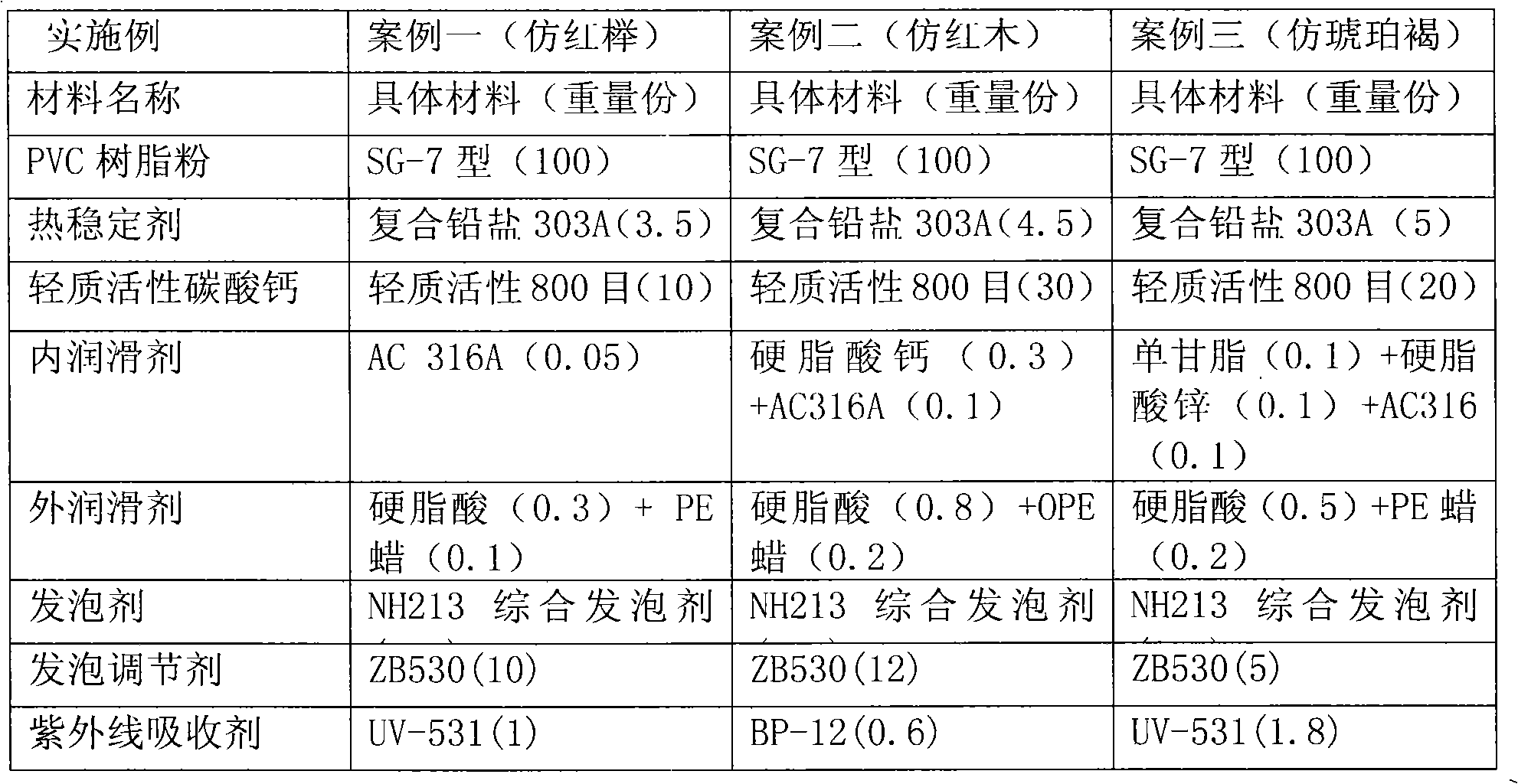

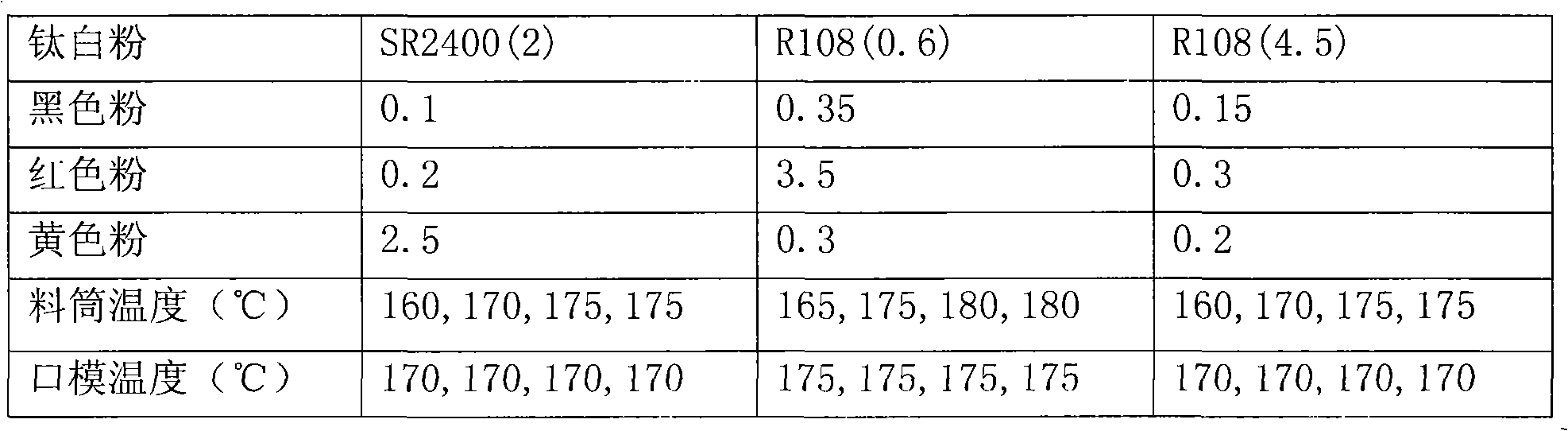

[0039]

[0040]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a high-weatherability imitation-wood crust foaming material with high hardness, good toughness, high weatherability and low cost. According to the invention, titanium pigment and an ultraviolet absorbent are added to a common forming material. High weatherability and high thermal stability of rutile type titanium dioxide are utilized; and excellent thermal stability, chemical stability and light stability of the ultraviolet absorbent are utilized. The two materials are adopted in combination in the foaming material, such that the thermolability of the PVC material is effectively reduced, and the weatherability of the foaming material is improved. Organic or inorganic toners are adopted, such that an imitation-wood effect can be achieved through the blending of the toners. With the technical scheme provided by the invention, the appearance of the material is improved; and the use of wood powder is avoided, such that use of wood is reduced. Therefore, the material is beneficial for environmental protection. With the material provided by the invention, the risks during the production and the application processes are reduced.

Description

technical field [0001] The invention relates to a foamed wood-plastic material, in particular to a PVC high-weather-resistant imitation wood-crust foamed material. Background technique [0002] Wood-plastic technology is a new type of material processing technology that has developed rapidly at home and abroad in recent years. Through reasonable technology and equipment, plastics and wood are mixed and processed with each other to produce wood-plastic products. Because the composite material contains plastic, it has a good modulus of elasticity. It is fully mixed with the contained fiber and plastic, so it has physical and mechanical properties equivalent to hardwood, such as compression resistance and bending resistance, and its durability is significantly better than ordinary wood. Material, high surface hardness, generally 2 to 5 times that of wood. Due to the existence of the above characteristics, wood-plastic technology has flourished at home and abroad in recent year...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L27/06C08K3/26C08K3/22C08J9/04

Inventor 方学军沈春建王琛裴智斌解双双黄寿磊黄贤德贾方瑞

Owner ANHUI GUANGDE JINPENG NEW MATERIAL MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com