Method for extracting yellow water through dripping cellar

A drip cellar and water pit technology, which is applied in the field of wine making, can solve the problems of increasing the amount of bran husks, low efficiency, and short drip cellar time, etc., and achieve the effects of improving output and quality, broad application prospects, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

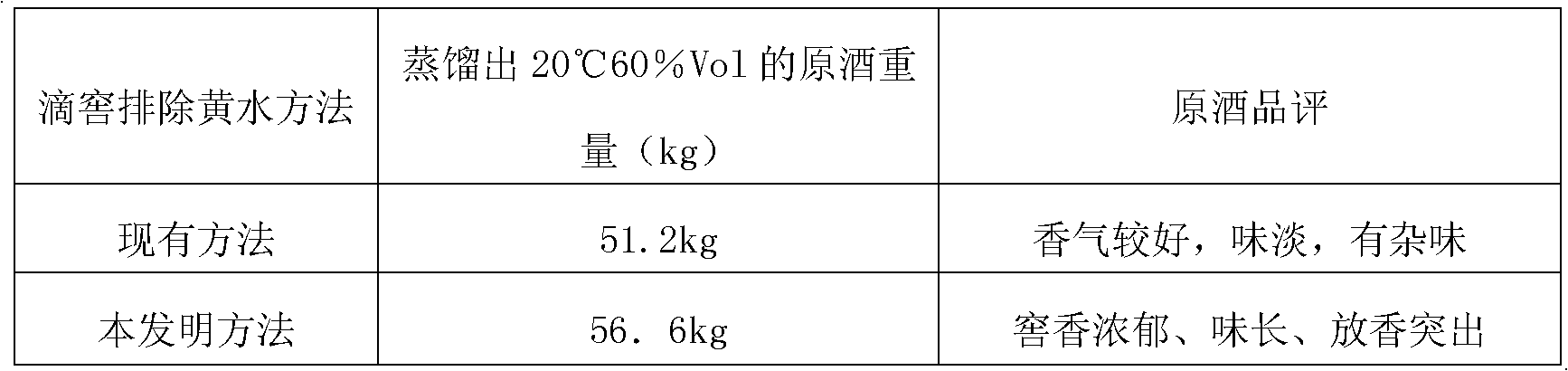

[0030] Embodiment 1 Using the method of the present invention to pump yellow water from the pit

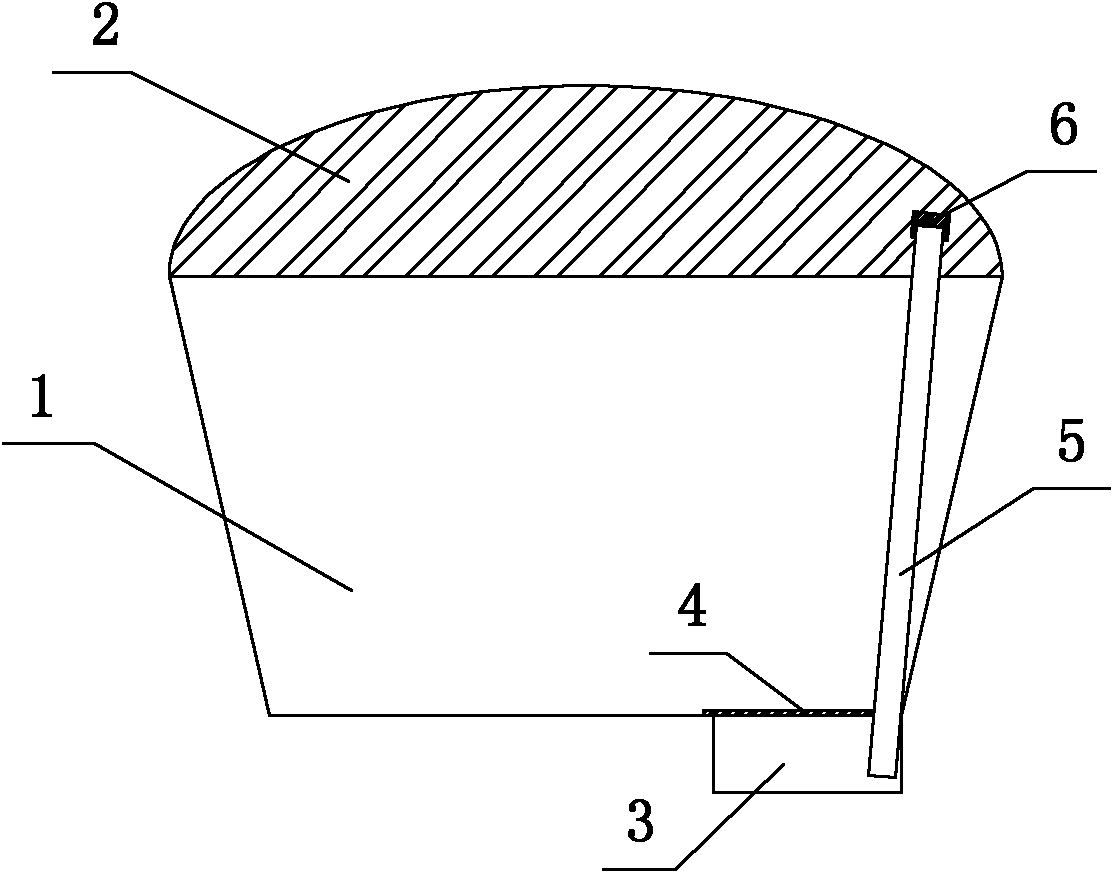

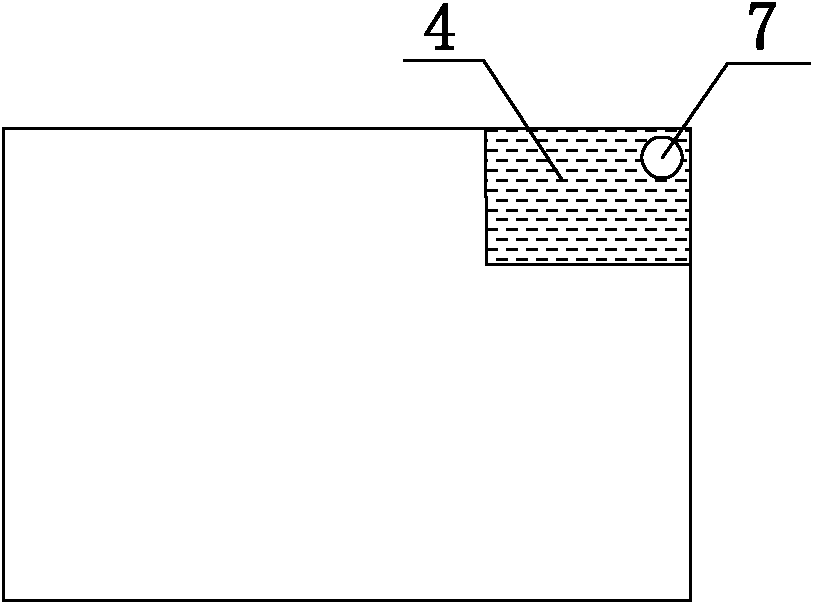

[0031] The method of pumping yellow water from dripping pit, such as figure 1 As shown, a yellow water pit 3 is arranged at the lowest bottom corner of the fermentation pit 1, the fermentation pit 1 is 2 meters deep, and the yellow water pit 3 is 0.8 meters long, 0.4 meters wide, and 0.4 meters deep. The bottom surface and the surrounding are casted with cement, and the thickness is 5 centimeters; 7 extends into the yellow water pit 3, the upper end of the bamboo bamboo pipe extends out of the fermentation cellar but does not extend out of the cellar cap, i.e. only extends into the cellar cap 2, and the upper end of the bamboo bamboo tube is provided with the bamboo Bamboo cover 6, the bamboo bamboo tube is 2.5 meters long and about 10 centimeters in diameter; the fermented grains are fermented in the fermentation cellar 1. After fermentation, 1 to 2 days before the cellar is ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com