High-flux cell electrofusion device based on microporous array film

A microwell array, high-throughput technology, applied in stress-stimulated microbial growth methods, biochemical instruments, biochemical equipment and methods, etc., can solve the problem of precise control of cells, high requirements for microwell positioning, and inability to perform large-scale application and other issues to achieve the effect of increasing fusion throughput and avoiding multi-cell fusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

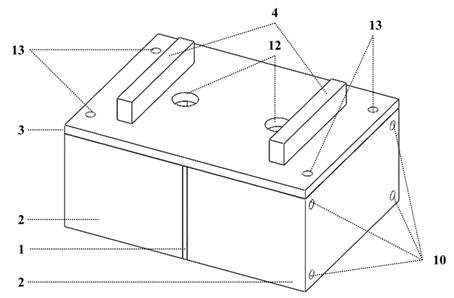

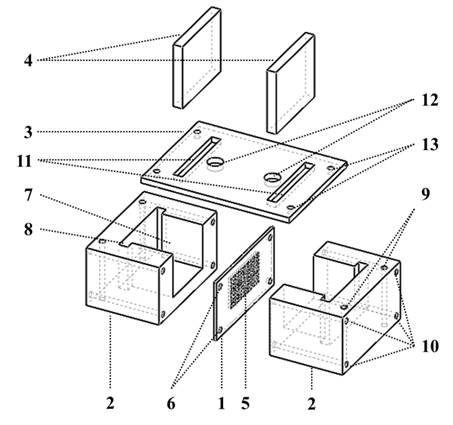

[0038] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 The shown high-throughput cell electrofusion device based on the microporous array film includes a microporous array film 1, two sample pools 2 respectively bonded to the two sides of the microporous array film 1, a microporous array film and two Cover slip 3 above the sample cell;

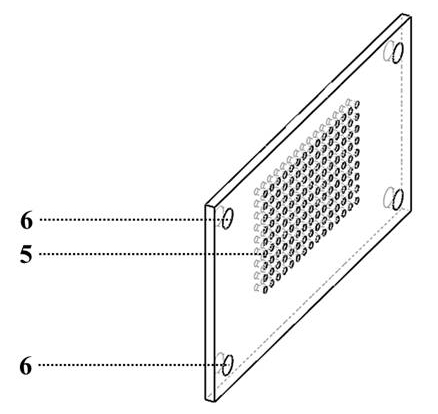

[0039] The middle part of the microporous array film 1 is provided with an array of micropores 5 , and the four corners are respectively provided with a first positioning hole 6 , and the lower ends of the two electrode plates 4 are respectively inserted into the two sample cells 2 through the cover sheet 3 .

[0040] Further, the two sample pools 2 have the same shape and structure and are left-right symmetrical. A cavity 7 for filling cell buffer and a groove 8 communicating with the cavity are resp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com