Method for preparing graphene/platinum nano counter electrode material for dye sensitized solar cell

A technology for solar cells and dye sensitization, applied in the field of dye-sensitized solar cells, can solve problems such as large-scale production and application limitations, and achieve the effects of improving catalytic effect, reducing cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

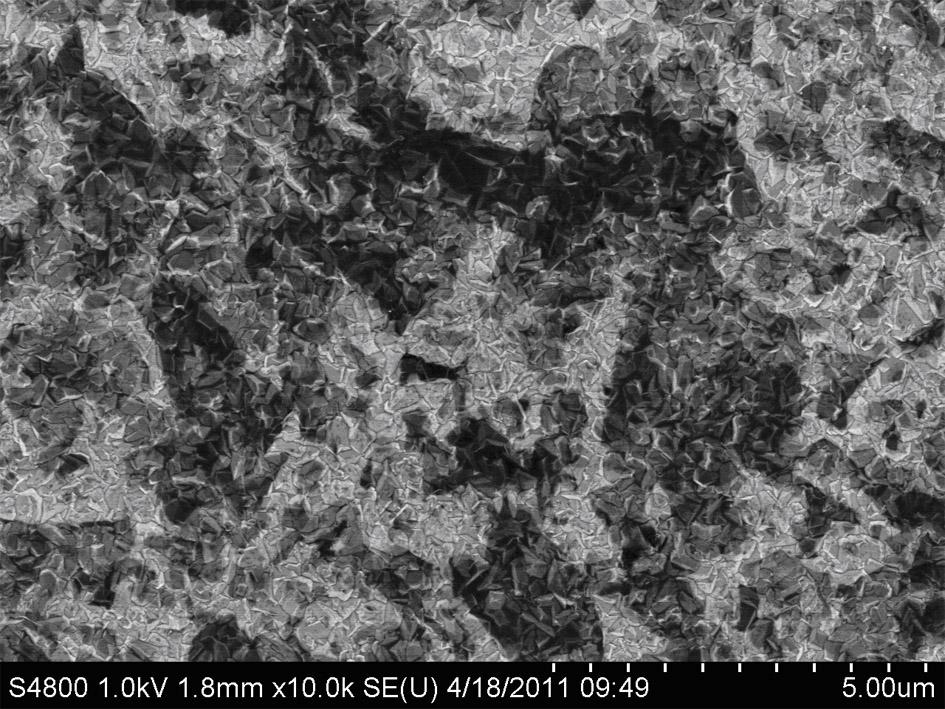

[0021] The cleaned conductive glass was immersed in an aqueous solution of polydiallyldimethylammonium chloride with a mass fraction of 0.5% for 2 h, rinsed with water after being taken out, blown dry, and then immersed in a graphene water with a mass fraction of 0.05% to suspend After being taken out, rinsed with water and air-dried, then immersed in the above polyelectrolyte for 2 h, rinsed with water and air-dried after taking out, and finally immersed in an aqueous solution of 0.05% chloroplatinic acid for 2 h. Rinse with water and blow dry to form a self-assembled ultrathin film with a structure of polyelectrolyte / graphene / polyelectrolyte / chloroplatinic acid. The above-mentioned ultra-thin films were sintered at 400 °C for 1 h in air to form an ultra-thin film with a structure of graphene / platinum nanoparticles.

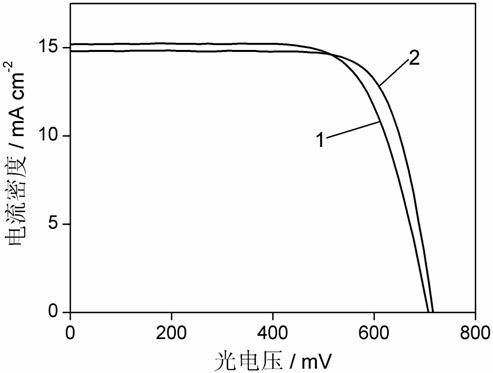

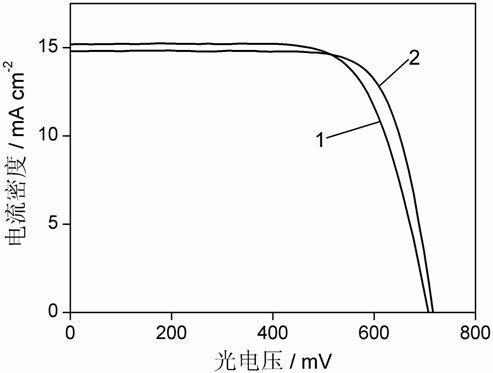

[0022] The ultrathin films were assembled as counter electrodes into DSSCs according to conventional methods with a cell area of 0.2304 cm 2 . The current-v...

Embodiment 2

[0024] The cleaned conductive glass was immersed in a polydiallyldimethylammonium chloride aqueous solution with a mass fraction of 2 % for 0.5 h, taken out, rinsed with water, blown dry, and then immersed in a 0.1 % mass fraction of graphene ethanol to suspend After taking it out, rinse it with ethanol and blow it dry, repeat the above self-assembly process once, then immerse it in the above polyelectrolyte for 0.5 hours, take it out, rinse it with water, blow it dry, and finally immerse it in chlorine with a mass fraction of 1 %. After 0.5 h in platinum acid aqueous solution, rinse with water and blow dry to form a structure of (polyelectrolyte / graphene) 2 / Self-assembled ultrathin films of polyelectrolyte / chloroplatinic acid. The above ultra-thin films were sintered at 450 °C for 1 h in air to form a structure of (graphene) 2 / Ultrathin films of platinum nanoparticles.

[0025] The ultrathin films were assembled as counter electrodes into DSSCs according to conventio...

Embodiment 3

[0027] The cleaned conductive glass was immersed in an aqueous solution of polydiallyldimethylammonium chloride with a mass fraction of 5 % for 0.2 h, taken out, rinsed with water, blown dry, and then immersed in an aqueous solution of 1 % mass fraction of chloroplatinic acid After being taken out, rinsed with water and air-dried to form a self-assembled ultrathin film with a structure of polyelectrolyte / chloroplatinic acid. The above ultra-thin films were sintered at 500 °C for 0.2 h in air to form ultra-thin films with a structure of platinum nanoparticles.

[0028] The ultrathin films were assembled as counter electrodes into DSSCs according to conventional methods with a cell area of 0.2304 cm 2 . The current-voltage (I-V) curve of the dye-sensitized solar cell was measured under AM1.5 simulated sunlight, and the open-circuit photovoltage ( V oc ) is 672 mV, the short-circuit photocurrent ( J sc ) is 10.12 mA / cm 2 , the fill factor ( FF ) is 0.68, the energy conv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com