Method for anaerobically degrading feather keratin with microbial strain 18D-TA

A feather keratin and microorganism technology, applied in the field of microorganisms, can solve the problems of increasing the time cost of industrial development, increasing the fermentation cost, large ventilation equipment, etc., and achieves the advantages of improving absorbability, short fermentation period and good substrate solubility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

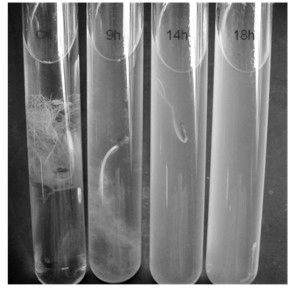

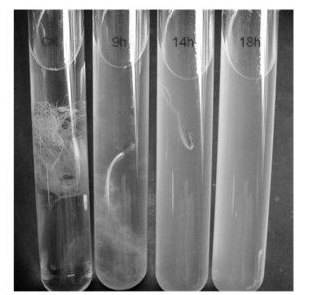

Image

Examples

Embodiment 1

[0027] The method for anaerobically degrading feather keratin using microbial strain 18D-TA is characterized in that the specific steps are as follows:

[0028] A. Feather treatment

[0029] After washing the feathers, put them in an oven at 45°C-55°C, and dry them for 2-3 days for later use;

[0030] B. Inoculation of strains

[0031] 1) Preparation of medium: Add 500ml of distilled water to a 1L Erlenmeyer flask in advance, add K 2 HPO 4 3 g / L, KH 2 PO 4 2.5 g / L, NaCl 3 g / L, MgSO 4 ·7H 2 O 0.02 g / L, CaCO 3 0.02 g / L vitamin solution 1% (v / v ), trace element solution 1% (v / v ) until dissolved, then add water to 1L, boil for 5-8min, cool to room temperature, add 0.1% (w / v v) Cysteine-HCl·H 2 O, adjust the pH to 7.0-7.5 with 5mol / L KOH, then add 0.1% (v / v) resazurin solution with a concentration of 0.1% (w / v), press 2.0m 3 / h pass N 2 , boiled for 15 minutes, cooled and divided into anaerobic tubes or serum bottles pre-added with 1% (w / v) feathers treated in step A, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com