Method for producing 2-dimethylamino-1, 3-dithiocyano-propane

A dithiocyano- and dimethylamino-based technology, which is applied in the field of synthesizing cartap intermediates, can solve the problems of low powder yield, low crystallization temperature, and long crystallization time of monosultap, and achieve long crystallization time and crystallization The effect of low temperature and easy crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

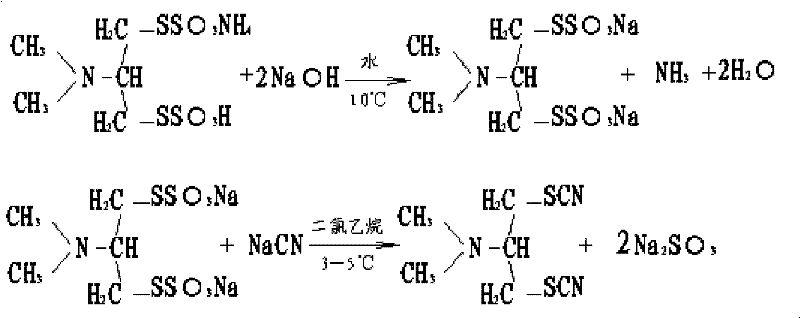

Method used

Image

Examples

Embodiment

[0018] The insecticidal monoammonium salt with a mass percentage content of 98% was prepared with water to form an insecticidal monoammonium salt solution with a mass concentration of 47.5%, stirred, and the pH value was adjusted to 10.25 with sodium hydroxide, and the temperature was lowered to 10°C. Sodium cyanide is prepared into a sodium cyanide aqueous solution with a mass concentration of 12.5%; in the sodium cyanide aqueous solution, add dichloroethane, stir, cool down to 4°C, add insecticidal monoammonium salt solution dropwise, continue stirring, dropwise add Time 60 minutes; keep warm at 4°C for 1.5 hours under stirring; stand at room temperature until the layers are separated, then separate the upper and lower layers, the lower organic layer is dichloroethane and 2-dimethylamino-1,3 - Dithiocyanate-propane, the upper inorganic layer is cyanide wastewater, which is subjected to centralized disinfection treatment.

[0019] Wherein, the molar ratio of the insecticidal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com