Functionalized carbon nanotube flame-retardant polylactic acid and preparation method thereof

A carbon nanotube and carbon nanotube masterbatch technology, which is applied in the field of materials, can solve the problems of poor mechanical properties of materials, inability to pass materials, and reduced heat release rate, and achieves improved flame retardant performance, mild process conditions, and preparation methods. Simple and effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

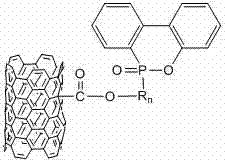

Method used

Image

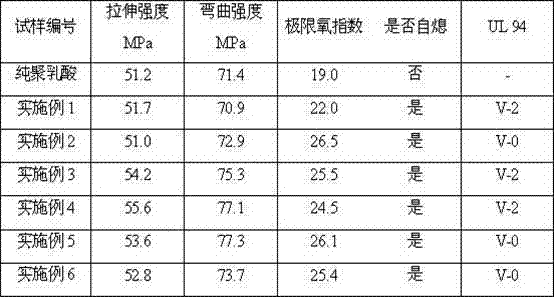

Examples

Embodiment 1

[0031] (1). Pure polylactic acid, functionalized carbon nanotubes, antioxidant triphenyl phosphite, and anti-dripping agent polytetrafluoroethylene are dried in vacuum at 30°C for 24 hours to remove moisture;

[0032] (2). 2g of pure polylactic acid and 1g of functionalized carbon nanotubes obtained in step (1) were dissolved in 40g of chloroform at 20°C, stirred and mixed, ultrasonically shaken for 1 hour, placed in a fume hood, evaporated the solvent, and dried After drying, the polylactic acid / carbon nanotube "masterbatch" is obtained.

[0033] (3). The polylactic acid / carbon nanotube "masterbatch" obtained in step (2) is pulverized, mixed with 196.6g pure polylactic acid, 0.2g triphenyl phosphite, and 0.2g polytetrafluoroethylene, and then mixed in a twin-screw extruder During extrusion, the product is cooled, pelletized, and dried to obtain functionalized carbon nanotube flame-retardant polylactic acid. The screw speed is 10 rpm, and the reaction extrusion temperature is 150...

Embodiment 2

[0035] (1). The pure polylactic acid, functionalized carbon nanotubes, antioxidant tris(2,4-di-tert-butylphenyl) phosphite, and anti-dripping agent polytetrafluoroethylene are dried in vacuum at 120℃ 1 hour to remove water;

[0036] (2). Dissolve 50g polylactic acid and 5g functionalized carbon nanotubes obtained in step (1) in 5000g chloroform at 20°C, stir and mix, ultrasonically shake for 5 hours, place in a fume hood, evaporate the solvent, and dry , Get the polylactic acid / carbon nanotube "masterbatch".

[0037] (3). The polylactic acid / carbon nanotube "master batch" obtained in step (2) is crushed and mixed with 35g pure polylactic acid, 5g tris(2,4-di-tert-butylphenyl) phosphite, and 5g polytetrafluoroethylene. , And then extrude in a twin-screw extruder, the product is cooled, pelletized, and dried to obtain functionalized carbon nanotube flame-retardant polylactic acid. The screw speed is 250 rpm, and the reaction extrusion temperature is 200°C.

Embodiment 3

[0039] (1) Combine pure polylactic acid, functionalized carbon nanotubes, antioxidant pentaerythritol bisphosphite bis(2,4-di-tert-butylphenyl) ester, and anti-drip agent polytetrafluoroethylene at 80°C Vacuum drying for 2 hours to remove moisture;

[0040] (2). Dissolve 25g of pure polylactic acid and 5g of functionalized carbon nanotubes obtained in step (1) in 500g of chloroform at 50°C, stir and mix, ultrasonically shake for 3 hours, place in a fume hood, evaporate the solvent, and bake After drying, the polylactic acid / carbon nanotube "masterbatch" is obtained.

[0041] (3). The polylactic acid / carbon nanotube "masterbatch" obtained in step (2) is crushed and mixed with 462g pure polylactic acid, 3g pentaerythritol bisphosphite bis(2,4-di-tert-butylphenyl) ester, and 5g polytetrafluoroethylene The ethylene is uniformly mixed and then extruded in a twin-screw extruder. The product is cooled, pelletized, and dried to obtain functionalized carbon nanotube flame-retardant polyla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com