Method for preparing phosphinic acid modified aluminum hydroxide flame retardant agents

A kind of aluminum hydroxide flame retardant, aluminum hydroxide technology, applied in dyeing low molecular organic compound treatment, fibrous filler, etc., can solve the problems of damaged material performance, poor compatibility, etc., to block the source of combustion and isolate oxygen , the effect of excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

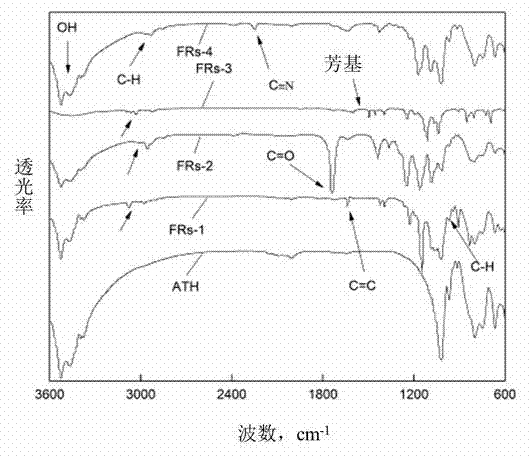

[0031] What this embodiment prepares is organic phosphinic acid modified aluminum hydroxide flame retardant, specific steps and conditions are:

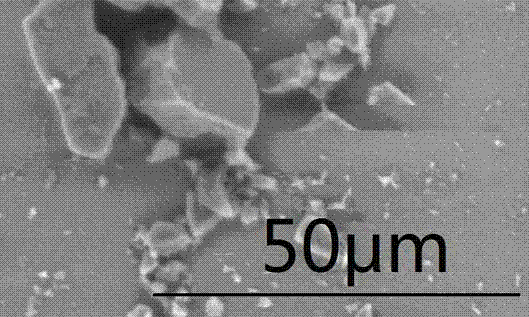

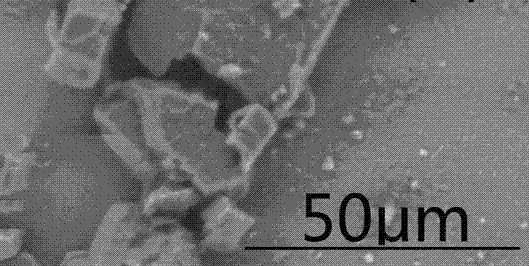

[0032] Diallylphosphinic acid modified aluminum hydroxide 2.8g (19.2mmol) diallylphosphinic acid, and 30ml acetic acid, deoxygenated with nitrogen, and added 1.0g aluminum hydroxide under stirring. After reacting at room temperature for 36 hours, the white precipitate was collected, filtered, washed with deionized water, ethanol, and acetone, and then vacuum-dried at 50° C. for 12 hours to obtain a fluffy white powder. Initial decomposition temperature: 278.0°C, weight loss: 19.5%. Secondary decomposition temperature: 488.6°C, weight loss: 26.8%.

Embodiment 2

[0034] What this embodiment prepares is organic phosphinic acid modified aluminum hydroxide flame retardant, specific steps and conditions are:

[0035] Bis(3-methoxy-3-oxopropyl)phosphinic acid modified aluminum hydroxide method is the same as case 5, finally get a white precipitate, filter, wash with deionized water, ethanol, acetone respectively, and then incubate at 50°C Dry under vacuum for 12 hours. The initial decomposition temperature is: 280.7°C, and the weight loss is: 16.3%. Secondary decomposition temperature: 382.0°C, weight loss: 30.6%.

Embodiment 3

[0037] What this embodiment prepares is organic phosphinic acid modified aluminum hydroxide flame retardant, specific steps and conditions are:

[0038] The method for modifying aluminum hydroxide with dibenzylphosphinic acid is the same as that of Case 5. Finally, a white precipitate is obtained, which is filtered, washed with deionized water, ethanol, and acetone, and then vacuum-dried at 50°C for 12 hours. The initial decomposition temperature is: 268.2°C, and the weight loss is: 4.47%. Secondary decomposition temperature: 495.9°C, weight loss: 65.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com