F-P (Fabry-Perot) cavity strained quantum well laser with low linewidth

A F-P, quantum well technology, applied in the direction of lasers, phonon exciters, laser components, etc., to achieve the effect of reducing spectral width and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

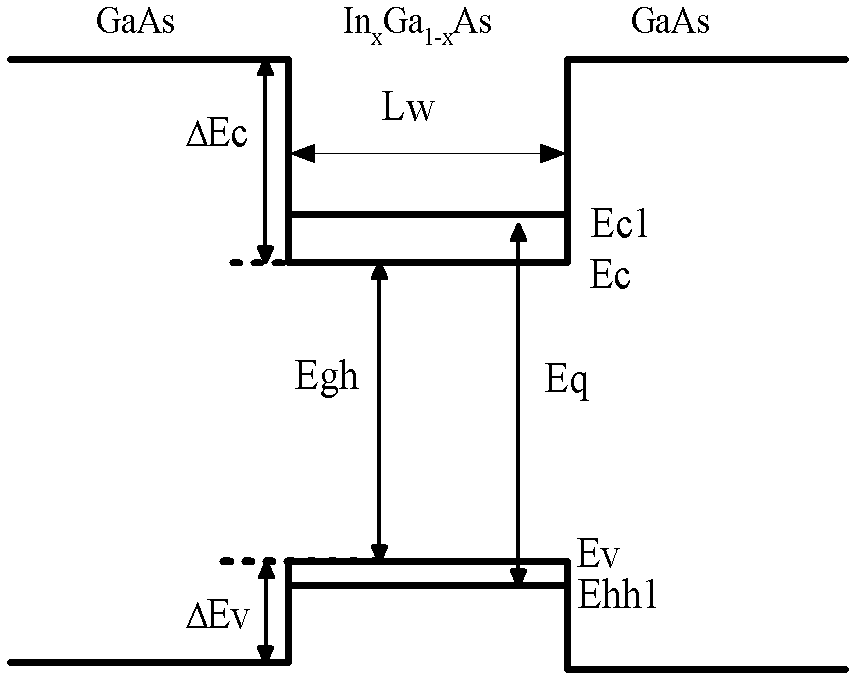

Method used

Image

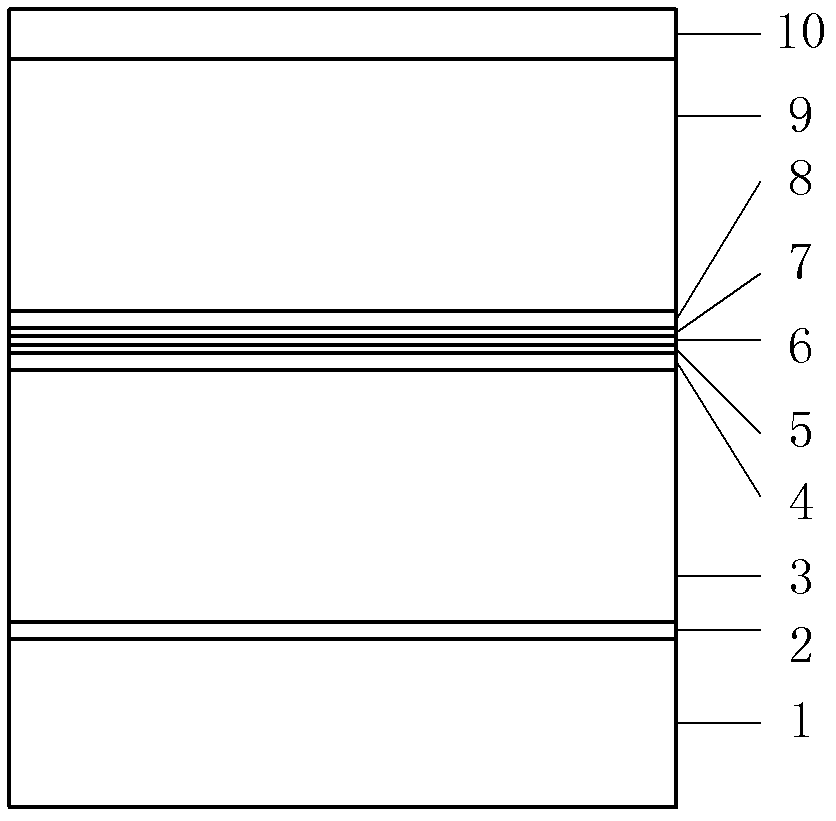

Examples

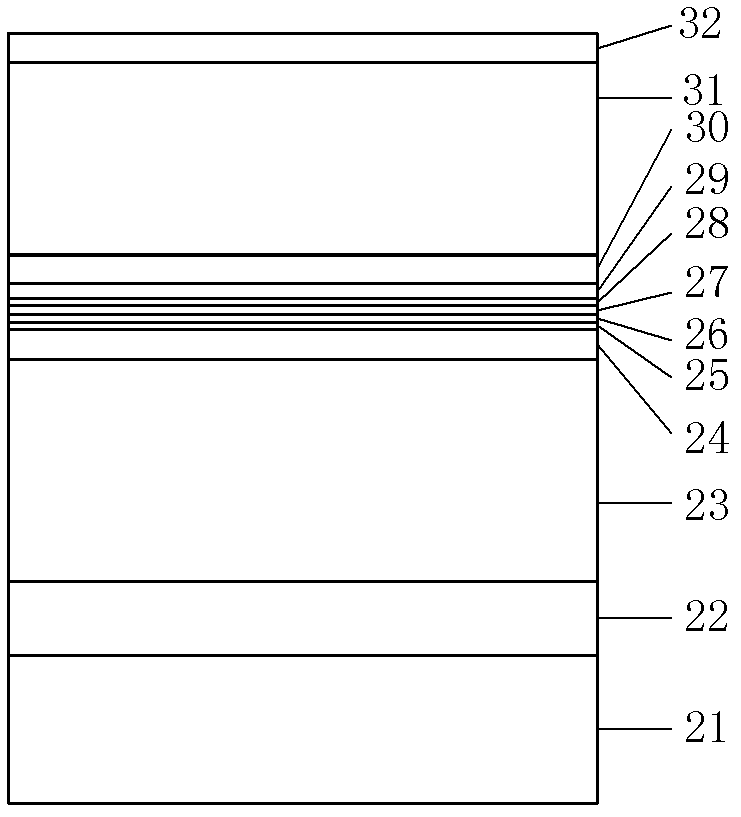

Embodiment 2

[0107] Embodiment 2 The active layer 6 has a thickness of 3nm, and the rest are the same as in Embodiment 1.

Embodiment 3

[0108] Embodiment 3 The active layer 6 has a thickness of 5 nm, and the rest are the same as in Embodiment 1.

[0109]References: [1] Henry C H 1982 Quantum Electron 18 259, [2] Du Baoxun 2004 Principles of Semiconductor Lasers (Beijing: Ordnance Industry Press), [3] Gerhardt N C, Hofmann M R, Hader J, Moloney J V, Koch S W, Riechert H 2004 Appl. Phys.Lett.84 1, [4] Toshiaki Suhara, Translated by Zhou Nansheng, Fundamentals of Semiconductor Lasers (Beijing: Science Press), p. 47, [5] Joachim P 2003 Semiconductor Optoelectronic Devices (California: Academic Press) p7 . , [9] Martin G, Botchkarev A, Rockett A, Morkoc H 1996 Appl.Phys.Lett.68 2541, [10] Huang Dexiu 1994 Semiconductor Optoelectronics (Chengdu: University of Electronic Science and Technology Press) p. 207, [11] Rodriguez D, Borruel L, Esquivias I, Wenzel H, Sumpf B, Erbert G 2004 Photonics Technology Letters 16 1432, [12] Gan K G, Bowers J E 2004 Photonics Technology Letters 16 1256, [13] Gerhardt N C, Hofmann M R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com