Production method for laver protein and polysaccharide nutrient powder

A technology of proteoglycan and production method, applied in the field of production of laver proteoglycan nutrient powder, achieving the effects of high extract yield, high extraction yield and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

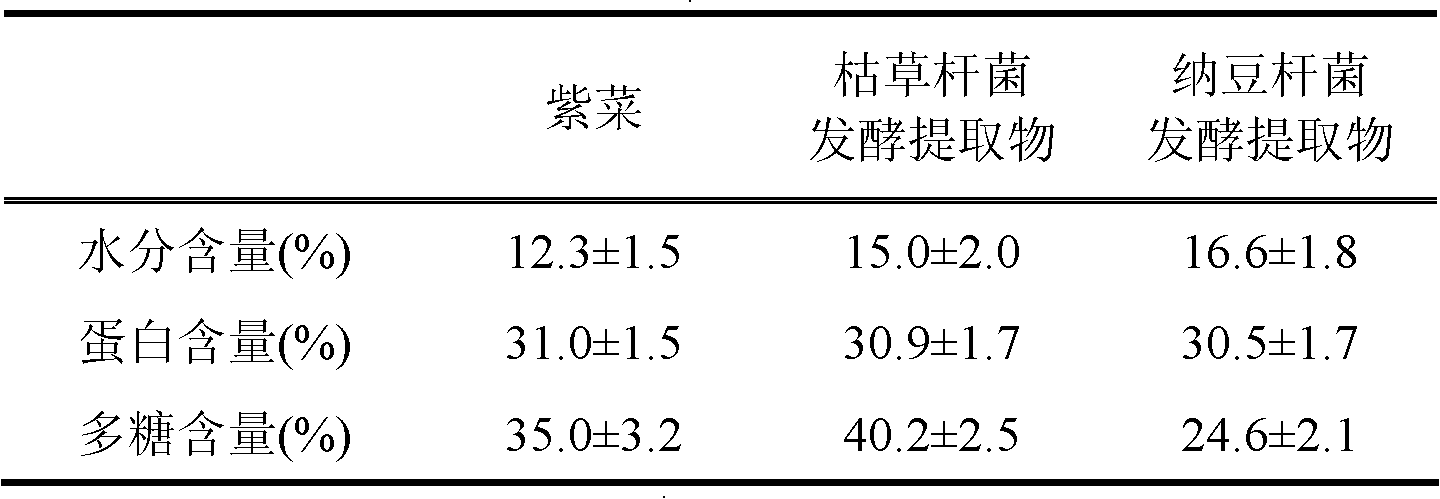

Embodiment 1

[0027] 1. Preparation of Bacillus subtilis bacteria liquid: The Bacillus subtilis strains were provided by the Microbiology Laboratory of Jimei University School of Bioengineering, cultured at 37°C for 8 hours using LB solid medium, and then picked out a single colony and then used LB liquid medium in the Cultivate at 37°C for 16 hours for the following laver fermentation.

[0028] 2. Preparation of laver fermentation liquid: put 8 g of laver into 200 ml of distilled water, add 4 ml of Bacillus subtilis bacterial liquid prepared in step (1) at the same time, ferment on a shaker at 30° C. for 24 hours, and prepare laver fermentation liquid.

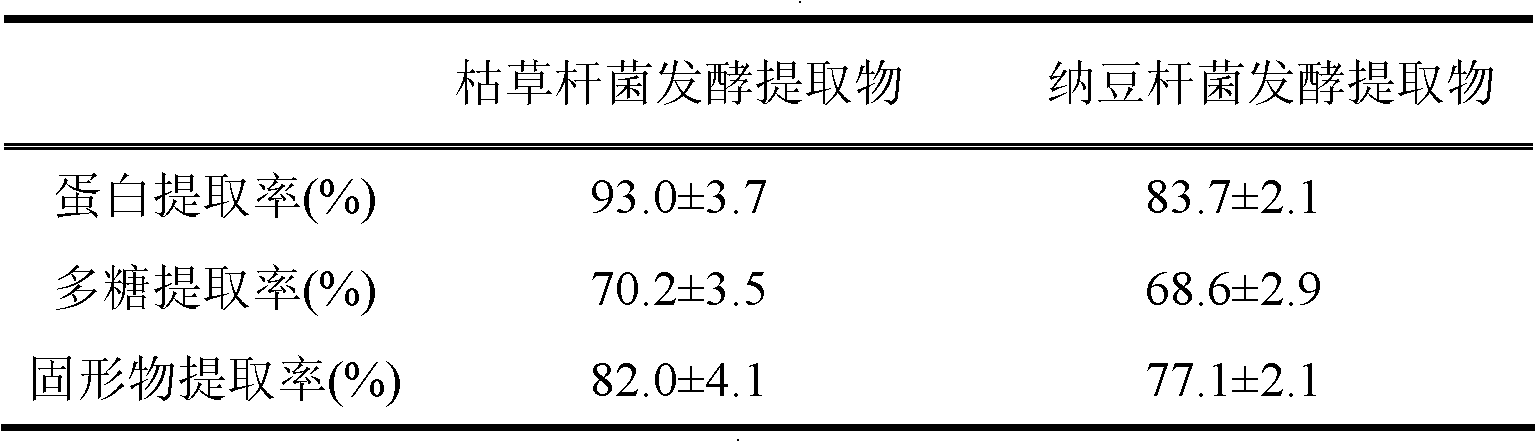

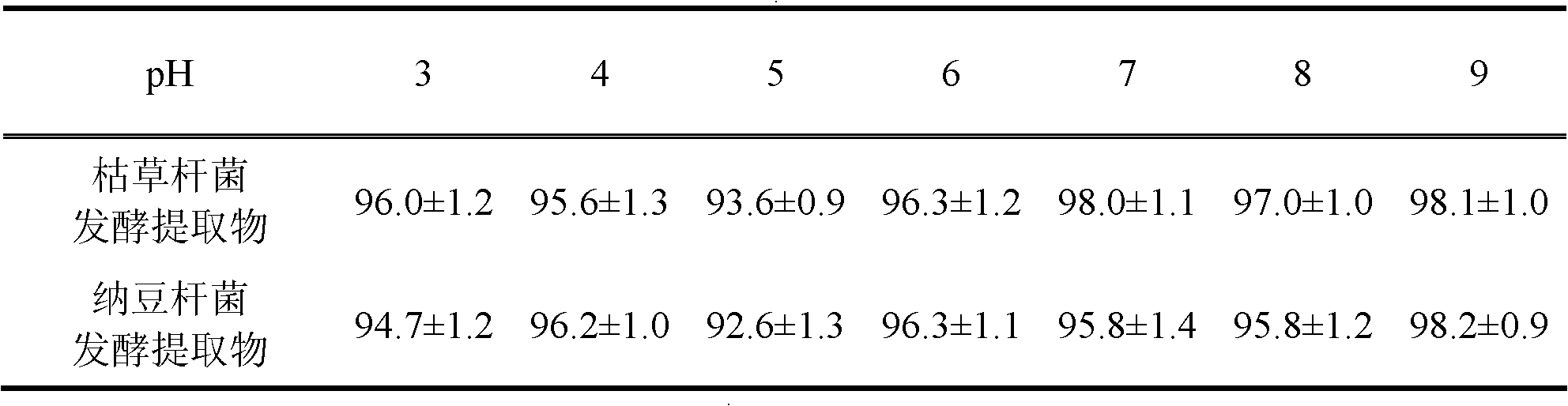

[0029] 3. Enzymolysis of seaweed fermentation liquid: adjust the pH of the seaweed fermentation liquid obtained in step (2) to 6.0 with acetic acid, add 0.2 g of papain (Guangxi Nanning Pangbo Biological Engineering Co., Ltd.), and enzymolyze at 55°C After 3 hours, remove insoluble impurities by centrifugation and filtration, and prepare l...

Embodiment 2

[0032] 1. Preparation of Bacillus natto bacteria liquid: Bacillus natto strains were provided by the Microbiology Laboratory of Jimei University School of Bioengineering, cultured at 37°C for 12 hours with LB solid medium, picked out a single colony and then cultured with LB liquid The base was cultured at 37°C for 24 hours for the following laver fermentation.

[0033] 2. Preparation of laver fermentation liquid: put 8 g of laver into 200 ml of distilled water, add 8 ml of Bacillus subtilis bacterial liquid prepared in step (1) at the same time, ferment on a shaker at 30° C. for 24 hours, and prepare laver fermentation liquid.

[0034] 3. Enzymolysis of laver fermentation liquid: use acetic acid to adjust the pH of the laver fermentation liquid obtained in step (2) to 5.5, and add 0.2 g of papain (Guangxi Nanning Pangbo Biological Engineering Co., Ltd.), and enzymolysis at 55°C After 2 hours, insoluble impurities were removed by centrifugation and filtration to prepare laver ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com