Method for extracting fucoxanthine-containing concentrate, product obtained through method, and application of product

A technology for fucoxanthin and concentrates, which is applied in the field of concentrates containing fucoxanthin. The field of concentrates containing fucoxanthin can solve the problems of increasing process complexity, shortening extraction time, and using a large amount of organic solvents. and other problems, to achieve the effect of low comprehensive cost, short extraction time and high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

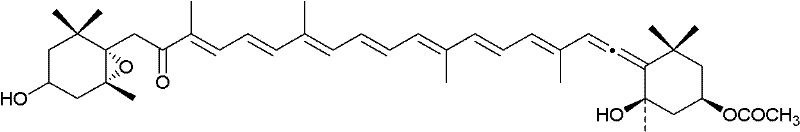

Image

Examples

Embodiment 1

[0084] Example 1 : The present invention contains the preparation of fucoxanthin concentrate

[0085] The implementation steps are as follows:

[0086] A. Raw material pretreatment

[0087] Rinse the remaining impurities and salt on the surface of the kelp with water, and place it in a GZX-9146MBE blast drying oven produced by Shanghai Boxun Industrial Co., Ltd. Medical Equipment Factory, dry it at a temperature of 35°C, and weigh 1kg of dried kelp. Grinding by high-speed shearing to ≤20 mesh.

[0088] B. Enzyme treatment

[0089] (1) Take 1000g of water and adjust the water temperature to 30°C, then add 1.0g of cellulase produced by Nanning Pangbo Bioengineering Co., Ltd. and 0.2g of pectinase produced by Nanning Pangbo Biological Engineering Co., Ltd., and then use hydrochloric acid or Adjust the pH of the solution to 6.0 with dilute sodium hydroxide aqueous solution, and activate it at a temperature of 30°C for 40 minutes, thus obtaining an enzyme treatment solution;

...

Embodiment 2

[0097] Example 2 : The present invention contains the preparation of the concentrate of fucoxanthin

[0098] The implementation steps are as follows:

[0099] A. Raw material pretreatment

[0100] Rinse the remaining impurities and salt on the surface of Sargassum with water, and place it in a GZX-9146MBE blast drying oven produced by Shanghai Boxun Industrial Co., Ltd. Medical Equipment Factory, and dry it at a temperature of 30°C. Weigh 1kg of dried horsetail Algae, crushed by high-speed shearing to ≤20 mesh.

[0101] B. Enzyme treatment

[0102] (1) Take 800g of water and adjust the water temperature to 40°C, then add 0.5g of cellulase produced by Nanning Pangbo Bioengineering Co., Ltd. and 0.4g of pectinase produced by Nanning Pangbo Biological Engineering Co., Ltd., and then use hydrochloric acid or Adjust the pH of the solution to 5.0 with a dilute sodium hydroxide aqueous solution, and activate it at a temperature of 40°C for 50 minutes, thus obtaining an enzyme tr...

Embodiment 3

[0110] Example 3 : The present invention contains the preparation of the concentrate of fucoxanthin

[0111] The implementation steps are as follows:

[0112] A. Raw material pretreatment

[0113] Rinse the residual impurities and salt on the surface of wakame with water, and place it in a GZX-9146MBE blast drying oven produced by Shanghai Boxun Industrial Co., Ltd. Medical Instrument Factory, and dry it at a temperature of 50°C. Weigh 1kg of dried wakame Vegetables, crushed by high-speed shearing to ≤20 mesh.

[0114] B. Enzyme treatment

[0115] (1) Take 1200g of water and adjust the water temperature to 50°C, then add 1.5g of cellulase produced by Nanning Pangbo Bioengineering Co., Ltd. and 0.3g of pectinase produced by Nanning Pangbo Biological Engineering Co., Ltd., and then use hydrochloric acid or Adjust the pH of the solution to 7.0 with dilute sodium hydroxide aqueous solution, and activate it at a temperature of 50°C for 60 minutes, thus obtaining an enzyme trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com