Technology for processing pulverized lignite

A treatment process, lignite technology, applied in the drying of peat, petroleum industry, solid fuel, etc., can solve the problems of difficulty in meeting the quality requirements of various users, large greenhouse gas emissions, and difficulty in large-scale development and utilization. The effect of low process cost, high calorific value and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

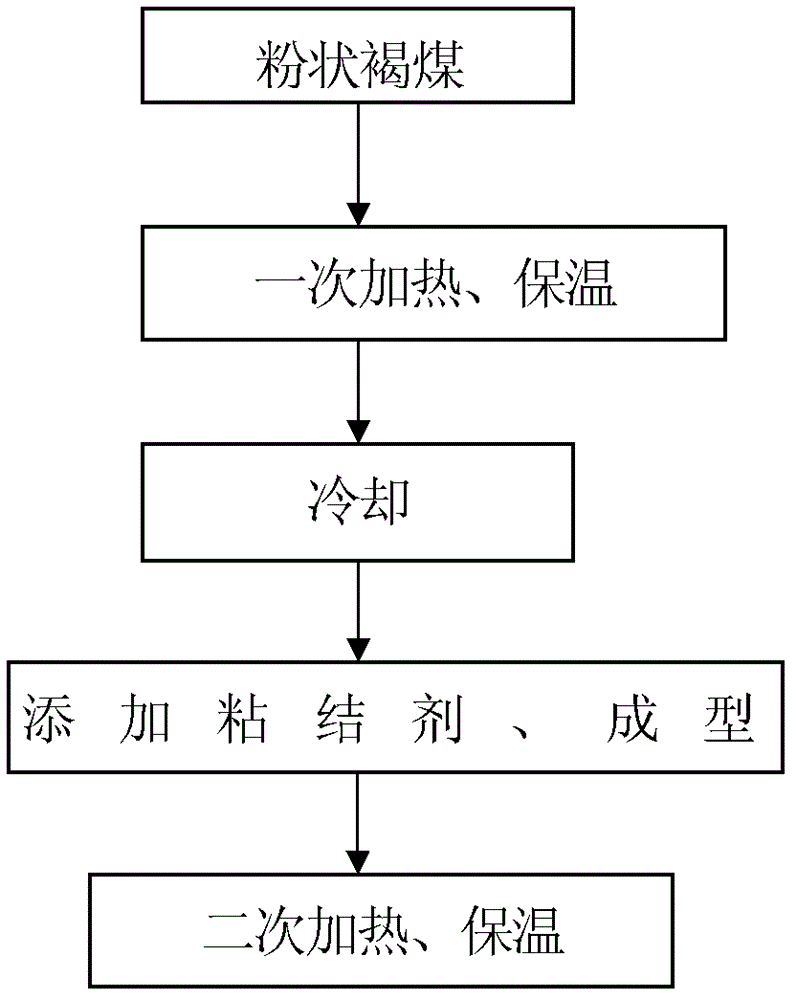

[0054] The processing technology of powdery lignite in the present embodiment may further comprise the steps:

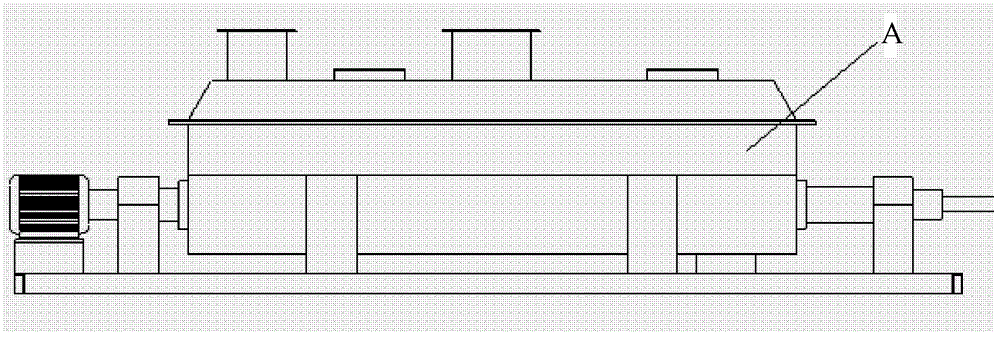

[0055] 1) The powdery lignite is heated and dried in a twin-screw drying device to remove moisture. The heating temperature is 300°C and the temperature is kept for 2 hours;

[0056] 2) Then, when the lignite obtained in step 1) is naturally cooled to 100°C, the material is discharged;

[0057] 3) Mix the cooled lignite with a binder, stir evenly, and then press the ball into shape;

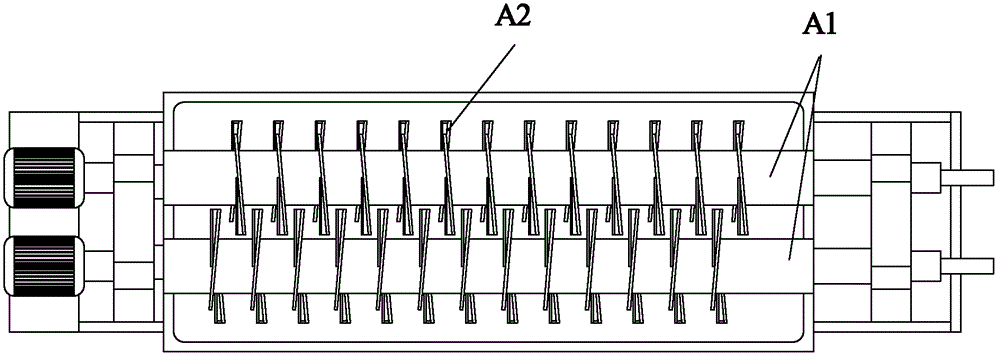

[0058] 4) Put the pellets into the fin reforming device, heat to 650°C, then keep the temperature for 2 hours, then cool the obtained coal to be reformed to 100°C, and discharge.

[0059] Wherein, in step 3), by weight, the addition ratio of lignite to binder is: 50 parts of lignite and 1 part of binder.

[0060] Wherein, by weight, the binder is made of 20 parts of PVFM solution, 2 parts of sodium humate, and 78 parts of water, wherein the PVFM solution includes: 4.85 parts of polyvi...

Embodiment 2

[0094] The processing technology of powdery lignite in the present embodiment may further comprise the steps:

[0095] 1) The powdery lignite is heated and dried in a twin-screw drying device to remove moisture. The heating temperature is 200°C and the temperature is kept for 3 hours;

[0096] 2) Then, when the lignite obtained in step 1) is naturally cooled to 80°C, the material is discharged;

[0097] 3) Mix the cooled lignite with a binder, stir evenly, and then press the ball into shape;

[0098] 4) Put the pellets into the fin reforming device, heat to 700°C, and then keep it warm for 2.5 hours, cool the obtained reformed coal to 100°C, and discharge.

[0099] Wherein, in step 3), by weight, the addition ratio of lignite and binder is: 50 parts of lignite and 50 parts of binder.

[0100] Wherein, by weight, the binder is made of 15 parts of PVFM solution, 4 parts of sodium humate, and 81 parts of water, wherein the PVFM solution includes: 5 parts of polyvinyl alcohol, 3...

Embodiment 3

[0102] The processing technology of powdery lignite in the present embodiment may further comprise the steps:

[0103] 1) The powdery lignite is heated and dried in a twin-screw drying device to remove moisture. The heating temperature is 300°C and the temperature is kept for 2.5 hours;

[0104] 2) Then, when the lignite obtained in step 1) is naturally cooled to 100°C, the material is discharged;

[0105] 3) Mix the cooled lignite with a binder, stir evenly, and then press the ball into shape;

[0106] 4) Put the pellets into the fin reforming device, heat to 650°C, then keep the temperature for 4 hours, then cool the obtained reformed coal to 100°C, and discharge.

[0107] Wherein, in step 3), by weight, the addition ratio of lignite and binder is: 80 parts of lignite and 30 parts of binder.

[0108] Wherein, by weight, the binder is made of 30 parts of PVFM solution, 2 parts of sodium humate, and 68 parts of water, wherein the PVFM solution includes: 2 parts of polyvinyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com