Preparation method of polycrystalline mercuric iodide thick film with high orientation

A mercury iodide, high-orientation technology, applied in chemical instruments and methods, polycrystalline material growth, crystal growth and other directions, to achieve the effects of low cost, simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

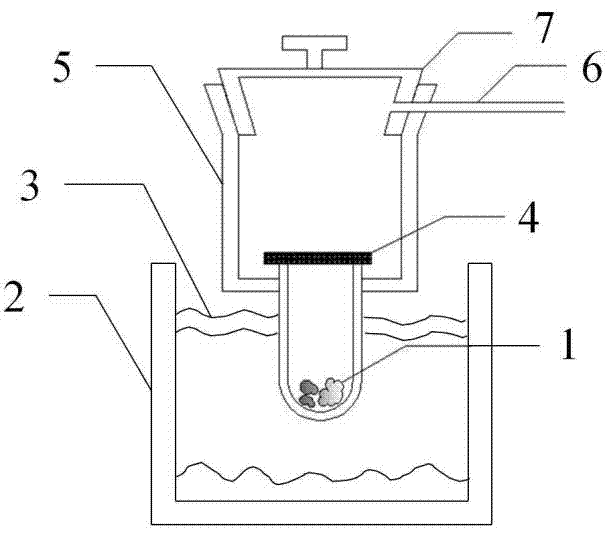

[0029] The technical process and steps in this experimental example are as follows:

[0030] 1. Preparation of mercuric iodide thin film as seed layer

[0031] a. Substrate substrate ITO preparation: Clean the surface of the ITO conductive glass, put it in acetone solution, absolute alcohol solution and deionized water solution for 15 minutes, and then dry the smooth ITO conductive glass.

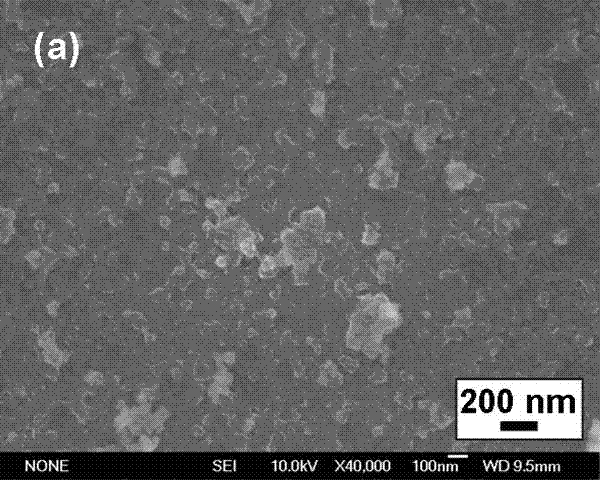

[0032] b. Preparation of mercuric iodide thin film: 2,7-dibromo-4-hydroxymercuryl fluorescent red disodium salt (also known as mercury bromide red), iodine tincture reagent according to [Hg 2+ ] and [I ? ], each prepared into a solution with a concentration of 20g / L, and the volume ratio of the two solutions is 1:3; the mixed solution of the two is poured into the experimental device; the rotating magnet in the actual device is Rotate at a speed of 500 rpm per minute to fully react the two reagents; after 0.5h, the free metal Hg + with I - The ions are fully combined to form HgI 2Molec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com