Preparation method of special-purposed coagulant used for treating printing and dyeing waste water

A technology for printing and dyeing wastewater and coagulant, which is used in textile industry wastewater treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of human health and living environment hazards, waste of water resources, and difficulty in meeting production and environmental protection requirements. , to achieve the effect of highlighting technological progress, good water solubility, and reducing COD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Prepare raw materials in parts by weight, take 70 parts of hydrochloric acid (solid content is 20%), 17 parts of sodium metaaluminate, 12 parts of ferrous chloride, 6 parts of aluminum potassium sulfate, 4 parts of sodium silicate, 2.5 parts of poly Allyl dimethyl ammonium chloride;

[0015] Its synthetic steps:

[0016] Sodium metaaluminate + ferrous chloride + potassium aluminum sulfate + hydrochloric acid → high polymer: the reaction condition is 130°C, stirring at constant temperature for 3 hours, then cooling down to 95°C;

[0017] High polymer + sodium silicate→inorganic high polymer: the reaction condition is 95°C, stirring at constant temperature for 1.5 hours, then cooling down to 35°C;

[0018] Inorganic high polymer + polydiallyl dimethyl ammonium chloride → mix evenly to get the finished special coagulant.

Embodiment 2

[0020] Optimum parts by weight to prepare raw materials, get 65 parts of hydrochloric acid (solid content is 20%), 15 parts of sodium metaaluminate, 10 parts of ferrous chloride, 5 parts of potassium aluminum sulfate, 3 parts of sodium silicate, 2.0 parts of poly Diallyldimethylammonium chloride;

[0021] Preparation: Add hydrochloric acid, sodium metaaluminate, ferrous chloride, and potassium aluminum sulfate into the reaction kettle in sequence, stir and heat to 135°C, react for 3 hours, and cool down to 95°C; add sodium silicate, react for 1.5 hours, and cool down to 35°C; add polydiallyl dimethyl ammonium chloride under stirring, and mix well to obtain coagulant.

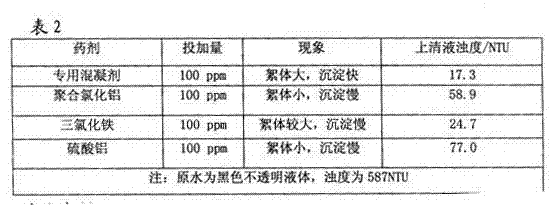

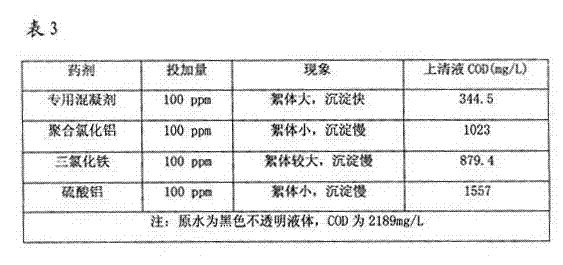

[0022] Performance verification of this product: compare the use effect of polyaluminum chloride, ferric chloride and aluminum sulfate by conventional methods, and evaluate its performance as follows:

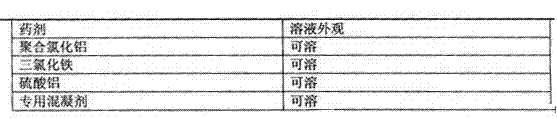

[0023] 1. Evaluation of water solubility

[0024] Add 4 kinds of medicines into 100ml of water sample respec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com