Polyaryletherketone imidazole and preparation method thereof

A technology for polyaryletherketimidazole and bisbenzimidazole, which is applied in the field of polyaryletherketimidazole and its preparation, can solve the problems of complex synthetic process route, high cost, low yield and the like, and achieves simple operation process, good resistance to The effect of heat resistance and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

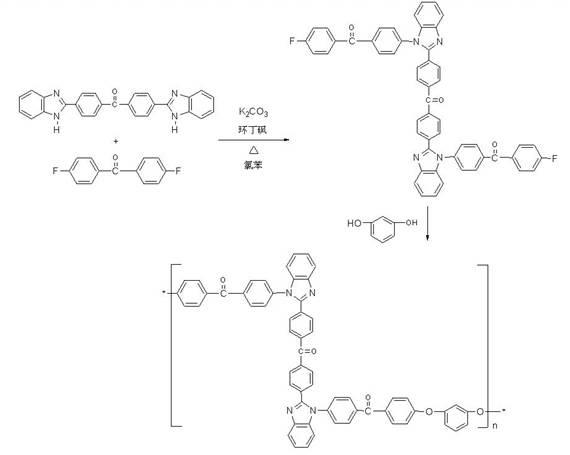

Method used

Image

Examples

Embodiment 1

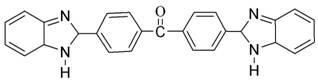

[0027] In a 50mL three-necked flask, add 0.01mol terephthalic acid, 0.022mol o-phenylenediamine, 2mL polyphosphoric acid and 8mL phosphoric acid. 2 Under the protection of , the reaction was stirred at 190 °C for 4 h. After the solution is cooled, pour it into 100 mL of cold distilled water, add 15% NaOH solution dropwise, and neutralize to pH=8. After the solution was allowed to stand for 6 h, it was suction filtered, washed with water, and dried to obtain a solid crude product. Dissolve the crude product in N,N- Dimethylformamide was recrystallized and vacuum-dried at 60°C to obtain bisbenzimidazole- .

[0028]

[0029] In a nitrogen atmosphere, bisbenzimidazole- 0.01 mol, 0.02 mol of 4'4-difluorobenzophenone, 0.04 mol of anhydrous potassium carbonate, 10 mL of sulfolane and 4 mL of chlorobenzene. The system was raised from room temperature to 145 °C and kept for 2 h. Then the temperature is raised from 145°C to 180°C, and the water separator allows the chlorobe...

Embodiment 2

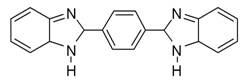

[0033] In a 50mL three-necked flask, add 0.01mol 4'4 diacid diphenyl ether, 0.022mol o-phenylenediamine, 2mL polyphosphoric acid and 8mL phosphoric acid. 2 Under the protection of , the reaction was stirred at 190 °C for 4 h. After the solution is cooled, pour it into 100mL of cold distilled water, add dropwise 15% NaOH solution, neutralize to pH=8, and generate a large amount of green precipitate. After the solution was left for 6 hours, it was suction filtered, washed with water and dried to obtain a solid crude product. The crude product was dissolved in absolute ethanol for recrystallization and vacuum drying at 60°C to obtain bisbenzimidazole- .

[0034]

[0035] In a nitrogen atmosphere, add benzimidazole- 0.01 mol, 0.02 mol of 4'4-difluorobenzophenone, 0.04 mol of anhydrous potassium carbonate, 10 mL of sulfolane and 4 mL of chlorobenzene. The system was raised from room temperature to 145 °C and kept for 2 h. Then the temperature is raised from 145°C to 180°...

Embodiment 3

[0039] In a 50mL three-necked flask, add 0.01mol 4'4 diacid benzophenone, 0.022mol o-phenylenediamine, 2mL polyphosphoric acid and 8mL phosphoric acid, in N 2 Under the protection of , the reaction was stirred at 190 °C for 4 h. After the solution is cooled, pour it into 100mL of cold distilled water, add dropwise 15% NaOH solution, neutralize to pH=8, and generate a large amount of green precipitate. After the solution was left for 6 hours, it was suction filtered, washed with water and dried to obtain a solid crude product. Dissolve the crude product in N,N-Dimethylformamide (DMF) was recrystallized and vacuum dried at 60°C to obtain bisbenzimidazole- .

[0040]

[0041] In a nitrogen atmosphere, bisbenzimidazole- 0.01 mol, 0.02 mol of 4'4-difluorobenzophenone, 0.04 mol of anhydrous potassium carbonate, 10 mL of sulfolane and 4 mL of chlorobenzene. The system was raised from room temperature to 145 °C and kept for 2 h. Then raise the temperature from 145°C to 19...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com