Preparation method for photosensitive and amphiphilic polyurethane-stabilized nano-zinc oxide

A nano-zinc oxide and amphiphilic technology, applied in the field of preparation of inorganic nano-materials, can solve the problems of large specific surface area, high modification efficiency and high specific surface energy of nanoparticles, and achieve easy industrial production, good dispersion stability, synthesis simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

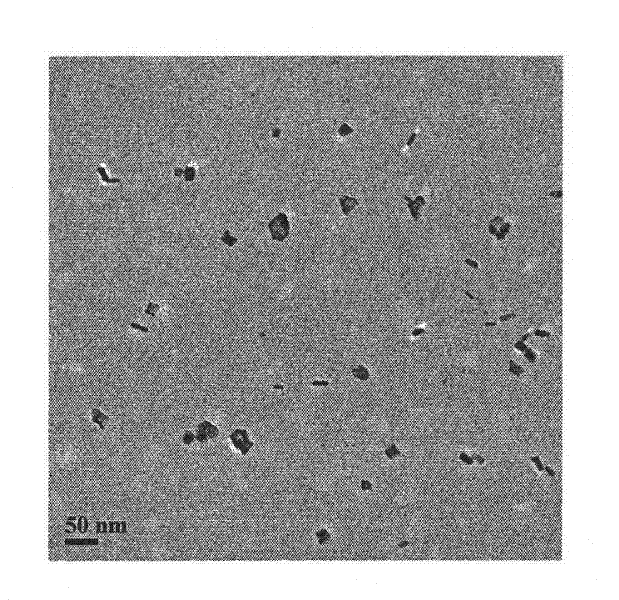

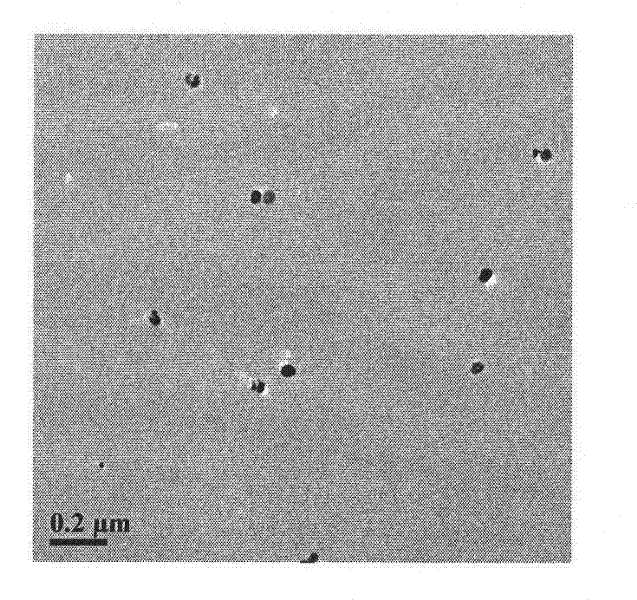

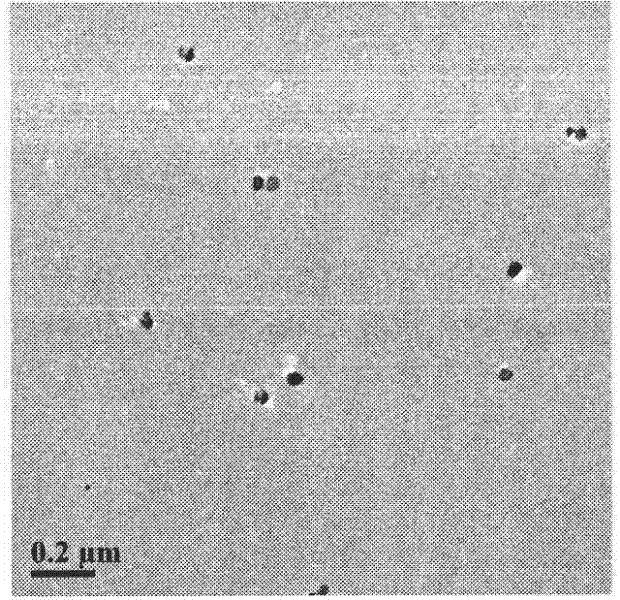

Image

Examples

Embodiment Construction

[0014] In order to better explain the present invention, the present invention will be further explained in detail below in combination with specific embodiments.

[0015] Case 1.

[0016] First, weigh two parts of polytetrahydrofuran type polyurethane, 0.2g each, and two parts of toluene, 11.7g each, mix 0.2g polyurethane and 11.7g toluene respectively in a small beaker according to the proportion, heat it at 65°C and keep stirring to fully dissolve (A.B. component); also weigh 0.4g of zinc acetate dihydrate and 1.1g of deionized water, mix zinc acetate and deionized water in a small beaker according to the proportion, heat it at 65°C until fully dissolved, and then ultrasonically 10 minutes (component C); weigh 0.15g of sodium hydroxide and 1.35g of deionized water, mix the sodium hydroxide and deionized water in a small beaker according to the proportion, heat it at 65°C until fully dissolved, and then Sonicate for 10 minutes (component D). Next, move component C into co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com