Method for preparing high-performance lithium iron phosphate / carbon anode material by microwave method

A technology of lithium iron phosphate and positive electrode materials, which is applied in battery electrodes, electrical components, circuits, etc., can solve the problems of weak wave absorption ability of lithium iron phosphate, and achieve the effect of easy operation, simple method and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 (comparative test)

[0036] Select ferrous oxalate, lithium hydroxide and ammonium dihydrogen phosphate raw materials, weigh them in a molar ratio of 1:1.02:1 and place them in an aqueous solution, add 8% glucose of the quality of the above raw materials, and simultaneously make the solid content reach 50%. After mixing in a high-energy ball mill for 7 hours until uniform, spray-dried, then placed in a resistance heating furnace, heat-treated at 350°C for 2h under the protection of argon, and then cooled to room temperature at 800°C for 10h to obtain the required phosphoric acid Lithium iron / carbon composite cathode material.

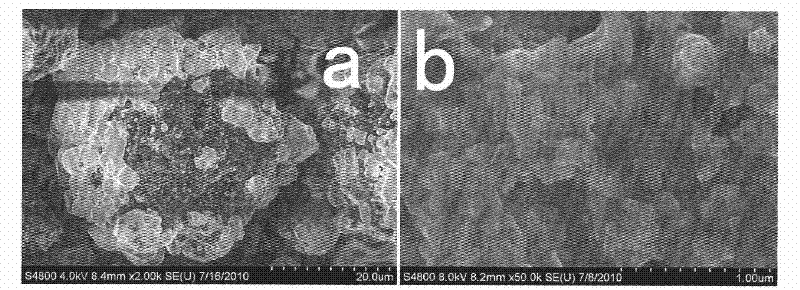

[0037] The scanning electron microscope pictures of the obtained material are shown in figure 1 a, It can be seen that the particles can grow to several microns.

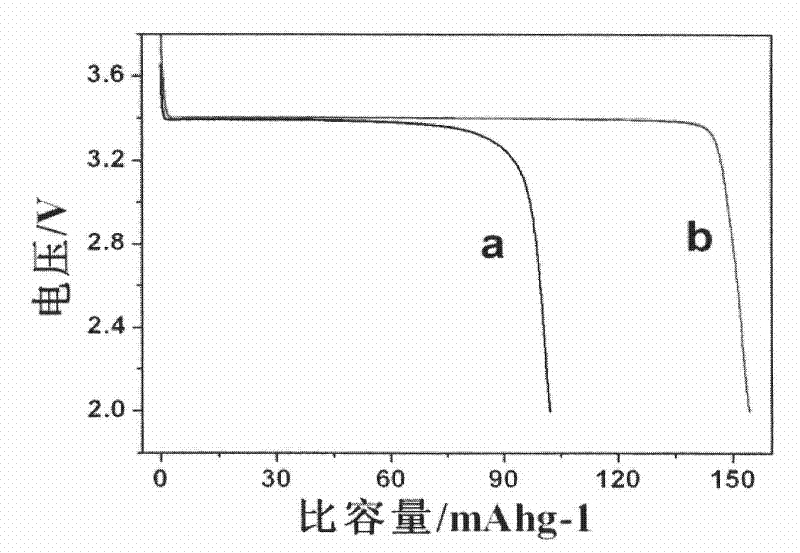

[0038] Electrochemical tests showed that ( figure 2 a), the material has a capacity of 101 mAh / g.

[0039] The conductivity of the material is 2X10 -5 S / cm.

Embodiment 2

[0041] Select ferrous oxalate, lithium hydroxide and ammonium dihydrogen phosphate raw materials, weigh them in a molar ratio of 1:1.02:1 and place them in an aqueous solution, add 8% glucose of the quality of the above raw materials, and simultaneously make the solid content reach 50%. After mixing in a high-energy ball mill for 7 hours until uniform, spray-dried, then placed in a microwave heating furnace, heat-treated at 350°C for 2 hours under the protection of a vacuum atmosphere, and then cooled to room temperature at 800°C for 10 hours to obtain the required iron phosphate Lithium / carbon composite cathode material. The vacuum degree is 5X10 1 Pa.

[0042] The scanning electron microscope pictures of the obtained material are shown in figure 1 b, It can be seen that the particles are about 100-300 nm in size.

[0043] Electrochemical tests showed that ( figure 2 b), the material has a capacity of 154mAh / g.

[0044] The electrical conductivity of the material is 5X1...

Embodiment 3

[0046] Select ferrous citrate, lithium hydroxide and ammonium dihydrogen phosphate raw materials, weigh them in a molar ratio of 1:1.02:1 and place them in an aqueous solution, add 8% polyvinyl alcohol of the quality of the above raw materials, wherein the solid content reaches 50 %, mixed evenly in a high-energy ball mill, sprayed after drying, and then placed in a microwave heating furnace, heat-treated at 350°C for 2h under the protection of a vacuum atmosphere, then heat-treated at 650°C for 10h and cooled to room temperature to obtain the required phosphoric acid Lithium iron / carbon composite cathode material. where the degree of vacuum is 10 2 Pa.

[0047] The material has a capacity of 158mAh / g and a conductivity of about 5X10 -5 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com