Tapered stereo-shaped array solar cell power generation system

A technology of solar cells and power generation systems, applied in photovoltaic power generation, light radiation generators, generators/motors, etc., can solve the problems of increased manufacturing time, increased manufacturing costs of solar panels, and limited efficiency, so as to reduce manufacturing costs and Time, improve photoelectric conversion efficiency, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

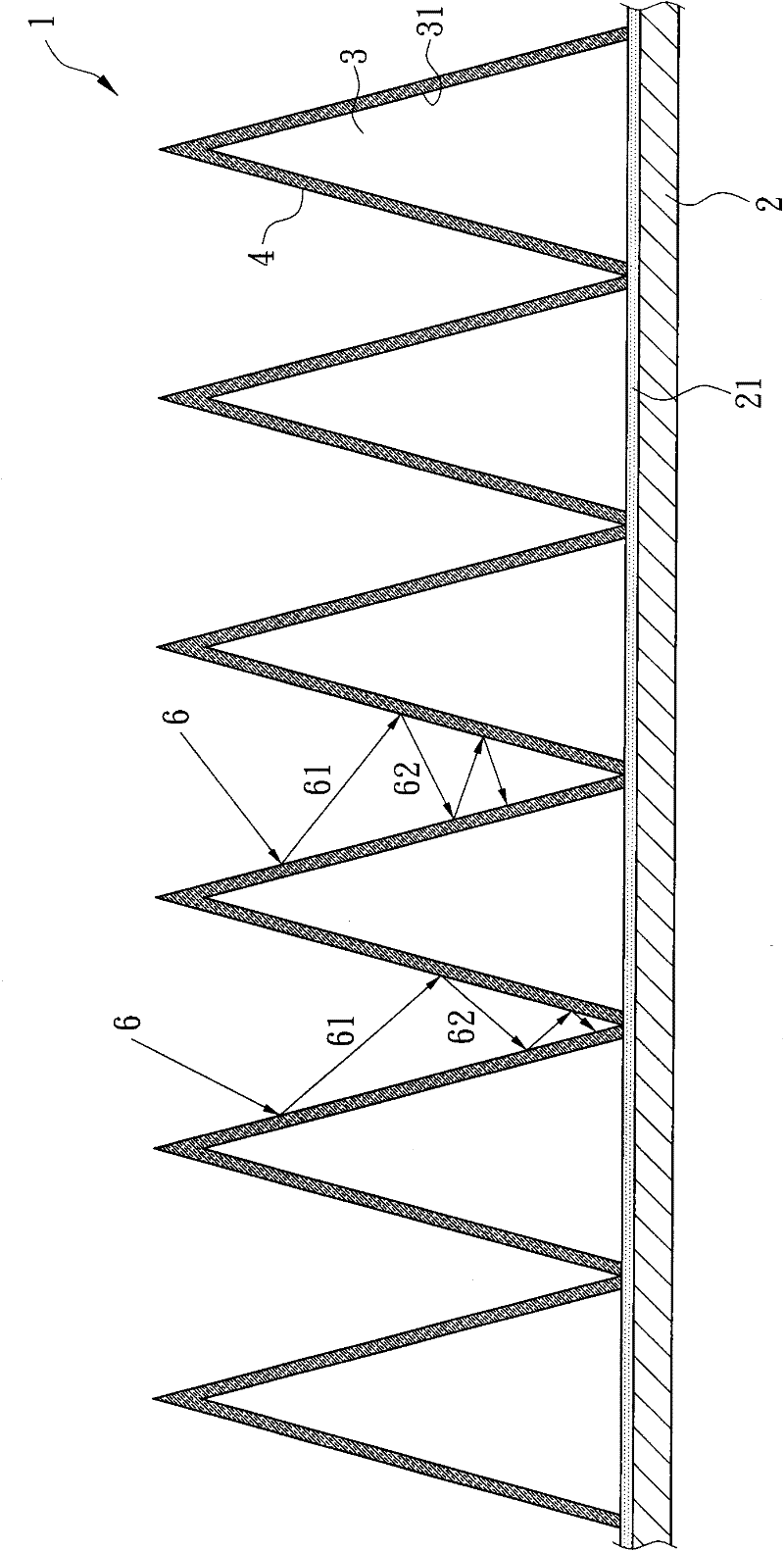

[0031] Please refer to Fig. 1 to Fig. 5, shown in the figure is the selected embodiment structure of the present invention.

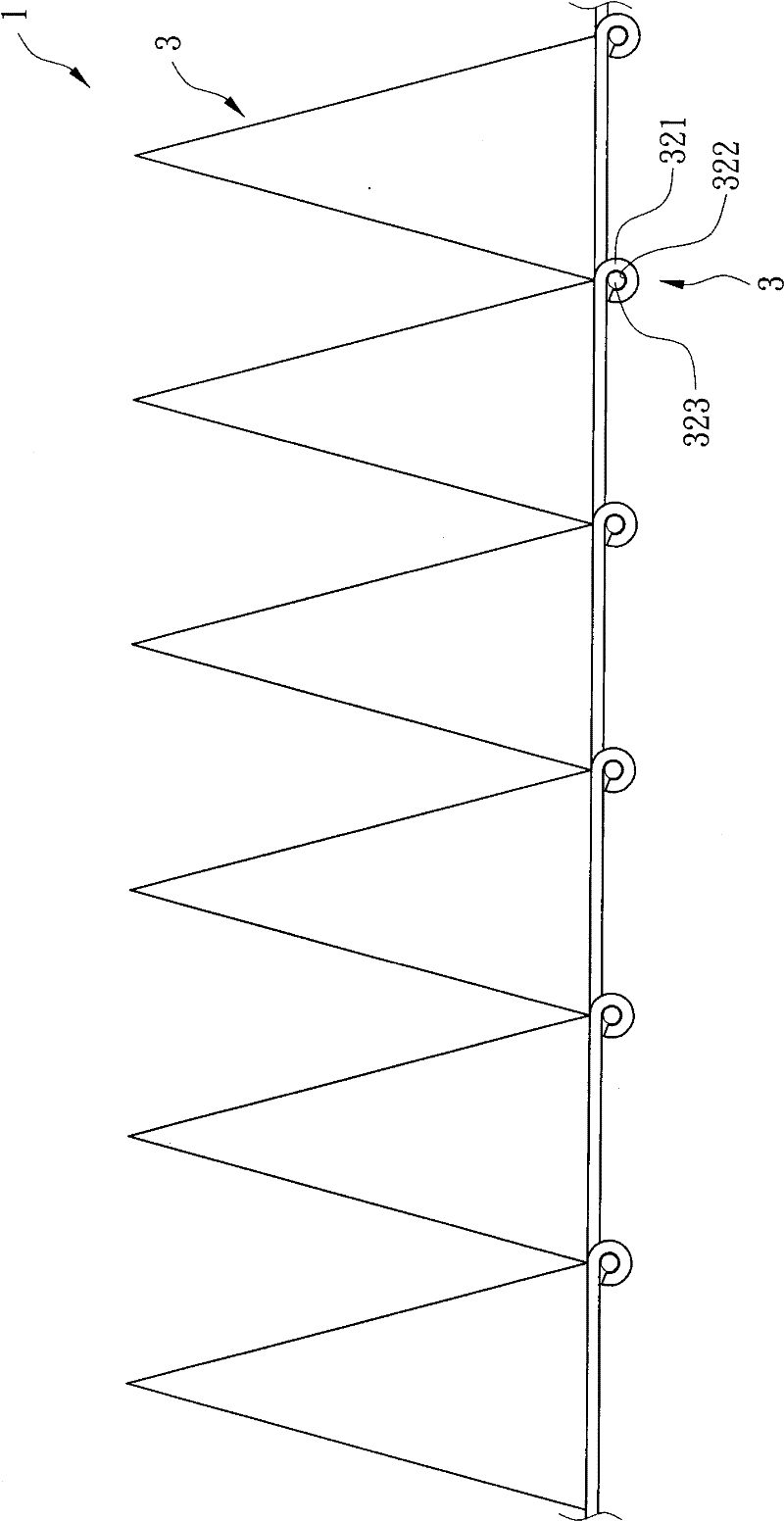

[0032] see Figure 1 ~ Figure 2 , the following is a description of an embodiment of the tapered three-dimensional array solar cell power generation system 1 of the present invention, which includes:

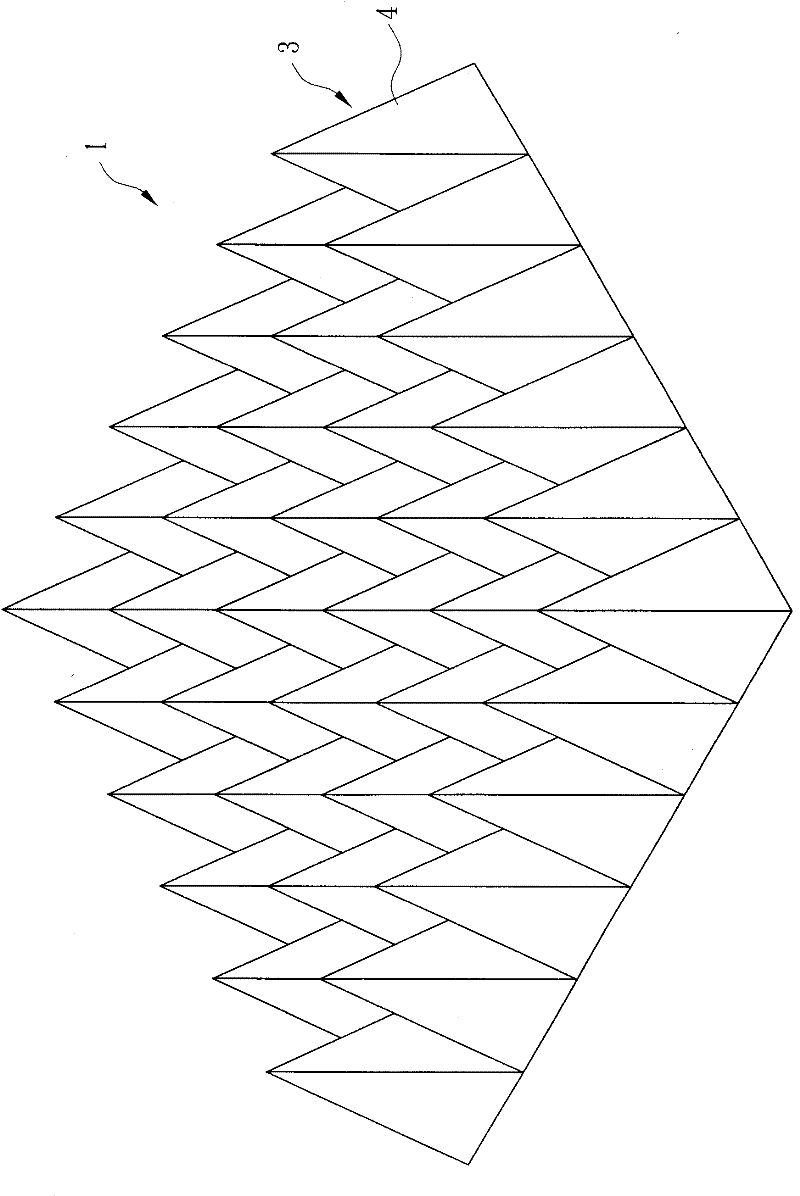

[0033] Several cones 3 are arranged in an array on a base layer 2, and are composed of panels 31 with at least three sides in a three-dimensional cone shape, and each cone of the several cones 3 is formed with a small cone angle and Form an array, wherein the shape of the bottom of each cone can be triangular, quadrangular or hexagonal, and the quadrangular shape includes square, rhombus and rectangle, etc., such as Figure 5 ~ Figure 6 As shown, when this embodiment is implemented, the bottom of the cone can be in various cone shapes such as triangle 51, square 52, rhombus 53, etc., depending on the spectral frequency band to be absorbed, that is, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com