Method for preparing m-pentadiene petroleum resin

A technology of petroleum resin and piperylene, which is applied in the field of preparation of piperylene petroleum resin, can solve the problems of complex post-treatment process and waste water generation, and achieve the effect of high selectivity, broad application prospect and simplified catalysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

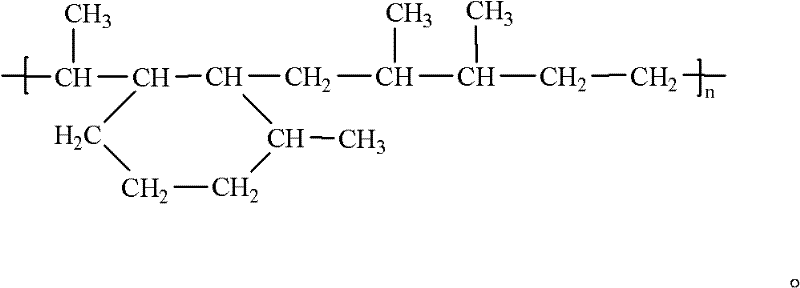

[0022] The invention provides a kind of preparation method of piperylene petroleum resin, and its steps and conditions are as follows:

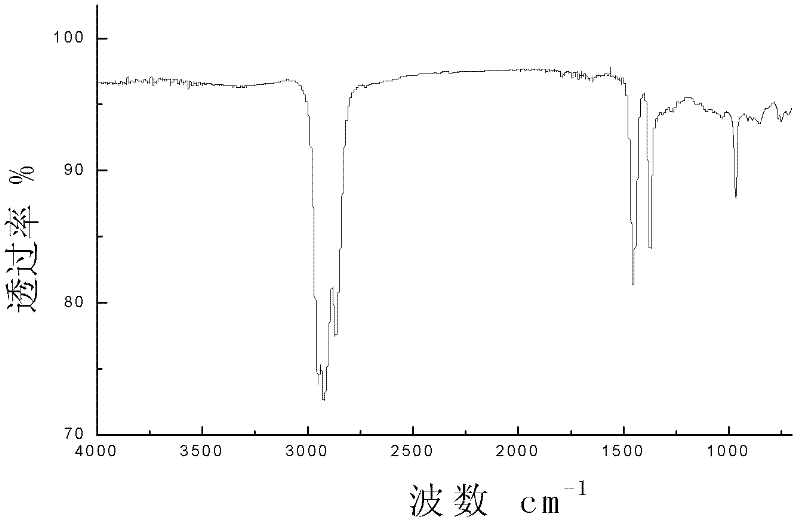

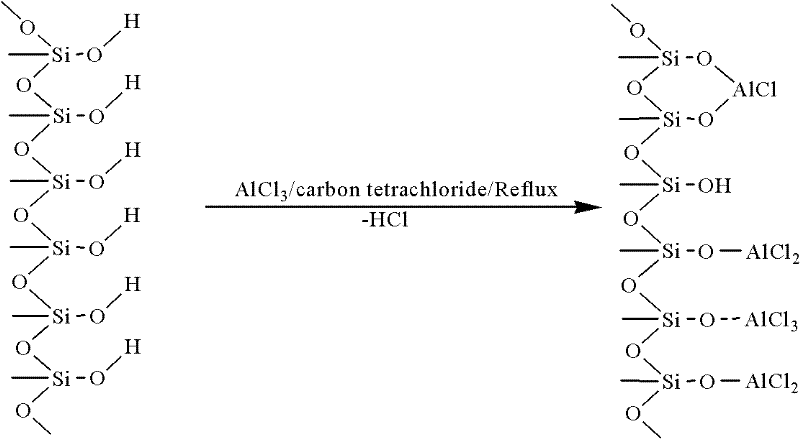

[0023] (1) The present invention has used a kind of composite catalyst system for synthetic piperylene petroleum resin, and it is the SiO of pretreatment 2 As a carrier, AlCl 3 loading onto pretreated SiO 2 On the support, get AlCl 3 / SiO 2 Supported main catalyst, pretreated SiO 2 :AlCl 3 The mass ratio of the catalyst and AlCl is 2:1; 3 / SiO 2 The mass ratio of the supported main catalyst is 1.25:100, and the cocatalyst is the liquid acid CH 4 o 3 S or H 3 PO 4 ; Pretreated SiO 2 is at 200°C, the SiO 2 Roast for 24h, or put SiO 2 After soaking in hydrochloric acid solution for 8 hours, dry it in vacuum at 80°C for 72 hours, and then use 30% H 2 o 2 After treatment for 8 h, vacuum drying at 80 °C for 72 h, the obtained pretreated SiO 2 ; Pretreated SiO 2 The specific surface area is 319m 2 / g, the pore volume is 0.9mL / g.

...

Embodiment 2

[0030] The conditions prepared in Example 2 are shown in Table 1, and the rest are the same as in Example 1. The obtained piperylene petroleum resin had a softening point of 95.3°C, a Gardner color of 2, and a resin yield of 76.5%.

Embodiment 3

[0031] The conditions for the preparation of Example 3 are shown in Table 1, and the rest are the same as in Example 1. The obtained piperylene petroleum resin had a softening point of 98.3° C., a Gardner color of 4, and a resin yield of 81.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com