Triazine carbon forming-foaming agent, synthesis method of the triazine carbon forming-foaming agent, and flame-retardant polymer composite material prepared from the triazine carbon forming-foaming agent

A technology of flame retardant polymer and synthesis method, which is applied in the field of flame retardant polymer composite materials, can solve the problems of high polarity of charcoal-foaming agent, poor surface smoothness, poor compatibility, etc., and achieve excellent flame retardant effect , good compatibility, and the effect of improving water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

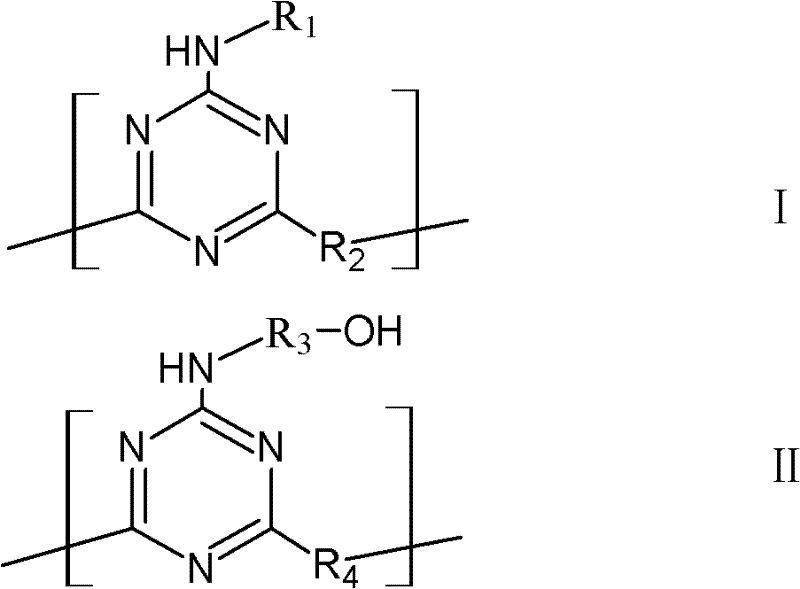

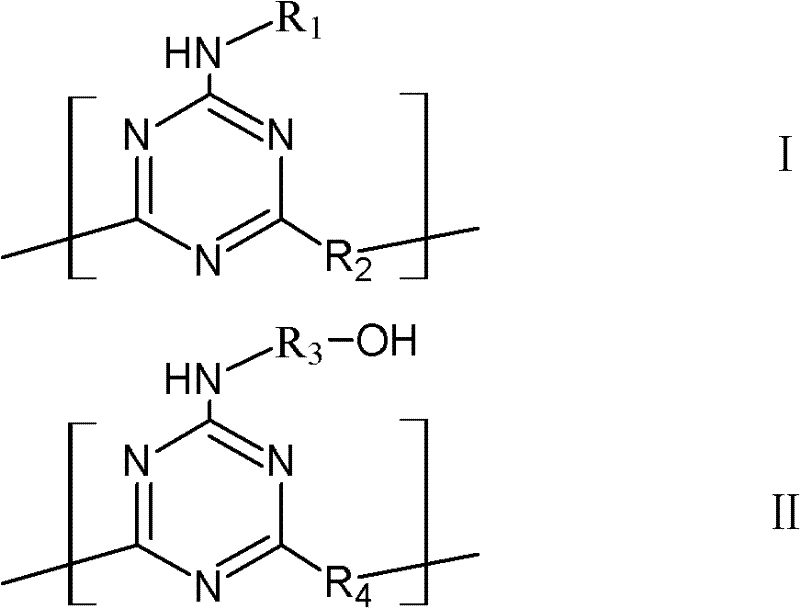

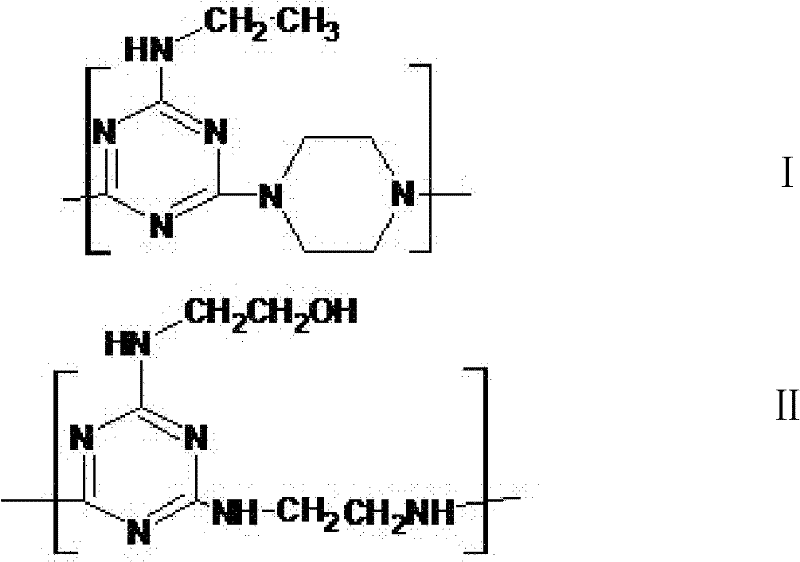

[0014] Specific embodiment one: the present embodiment triazine series char-forming-foaming agent is the random copolymer that is made up of structural unit represented by following general formula I and II;

[0015]

[0016] Wherein the molar ratio of above-mentioned structural unit I and II is 01 =C n1 H2 n1+1 , n1=1~10; R 2 =-NH(CH 2 ) n2 NH-, Among them n2=2~6; R 3 =C n3 h 2n3 , n3=2~4; R 4 =-NH(CH 2 ) n2 NH-, Wherein n2=2~6.

specific Embodiment approach 2

[0017] Specific embodiment two: the synthetic method of the described triazine series char-forming-foaming agent of specific embodiment one, carry out according to the following steps: one, take cyanuric chloride as starting raw material, take inorganic alkali as acid-binding agent, Add cyanuric chloride into the reaction vessel, add a solvent into the reaction vessel to disperse the cyanuric chloride evenly, add alcohol amine, alkylamine and acid-binding agent dropwise to the reactor under the condition of -5~10°C, The acid-binding agent is added dropwise, so that the pH of the solution is 5-8. After 2-4 hours of reaction, the first step of substitution reaction is completed, and a substituted product of cyanuric chloride, 2-hydroxyalkylamino-4,6 -Dichloro-1,3,5-triazine and 2-alkylamino-4,6-dichloro-1,3,5-triazine, wherein the mass ratio of alcoholamine to alkylamine is 1~ 50:1; 2. Raise the temperature to 30-50°C, then add diamine and acid-binding agent dropwise, and contro...

specific Embodiment approach 3

[0019] Embodiment 3: This embodiment is different from Embodiment 2 in that: in step 1, the solvent is acetone, water or a mixture of acetone and water. Others are the same as in the second embodiment.

[0020] In this embodiment, when the solvent is a mixture, acetone and water are mixed in any ratio.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermogravimetric decomposition temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com