Water-based ink for plastic printing and preparation method thereof

A technology of plastic printing and plastic ink, which is applied in the direction of ink, application, household utensils, etc., to achieve the effect of considerable market potential, meeting hygienic requirements, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

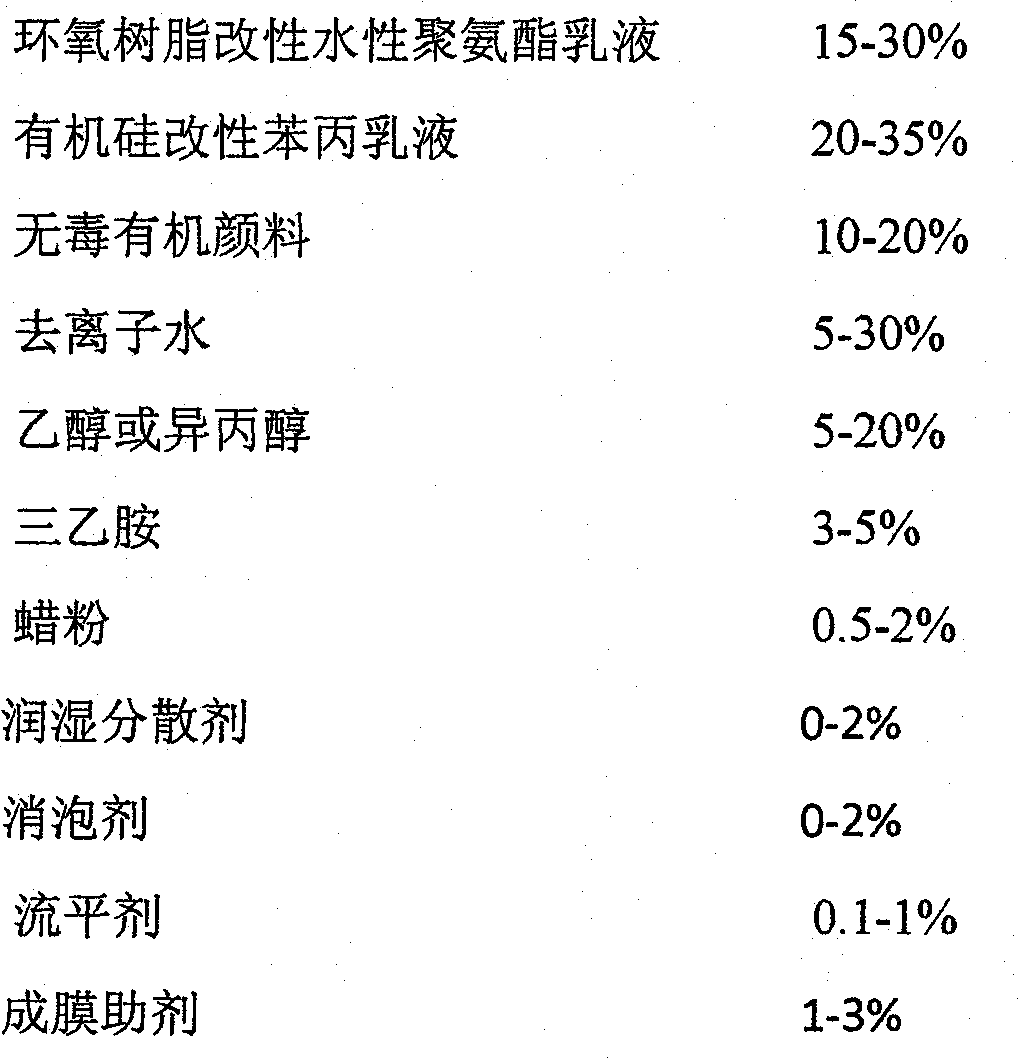

[0043] Prepare a kind of plastic printing water-based ink, the raw material composition of present embodiment is as follows:

[0044]

[0045]

[0046] Prepare water-based ink for plastic printing according to the above specific formula data. The wax powder in the formula refers to micronized polyethylene wax; the wetting and dispersing agent in the formula refers to a mixture of high molecular weight nonionic and anionic surfactants; The defoamer in the formula refers to the defoamer for CF 87 water-based ink whose components are mineral hydrocarbons or the defoamer for CF 481 water-based ink whose components are mineral hydrocarbons, silicon dioxide and surfactants; Leveling agent refers to organically modified polydimethylsiloxane solution, such as W-3018 leveling agent for water-based coatings, HX-5600 leveling agent for water-based coatings, etc.; the film-forming aid in the formula refers to alcohol ether class of compounds.

Embodiment 2

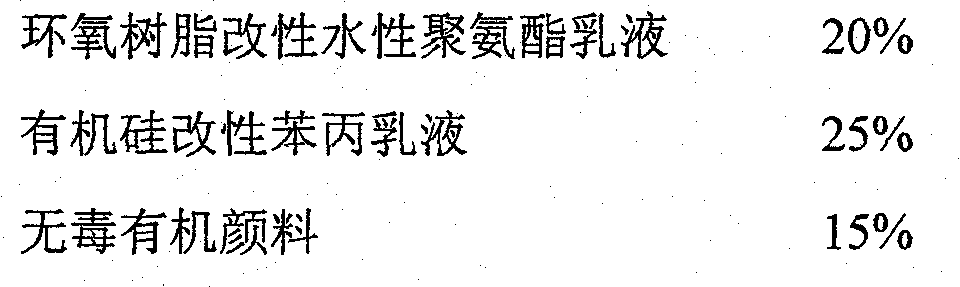

[0062] Prepare a kind of plastic printing water-based ink, the raw material composition of present embodiment is as follows:

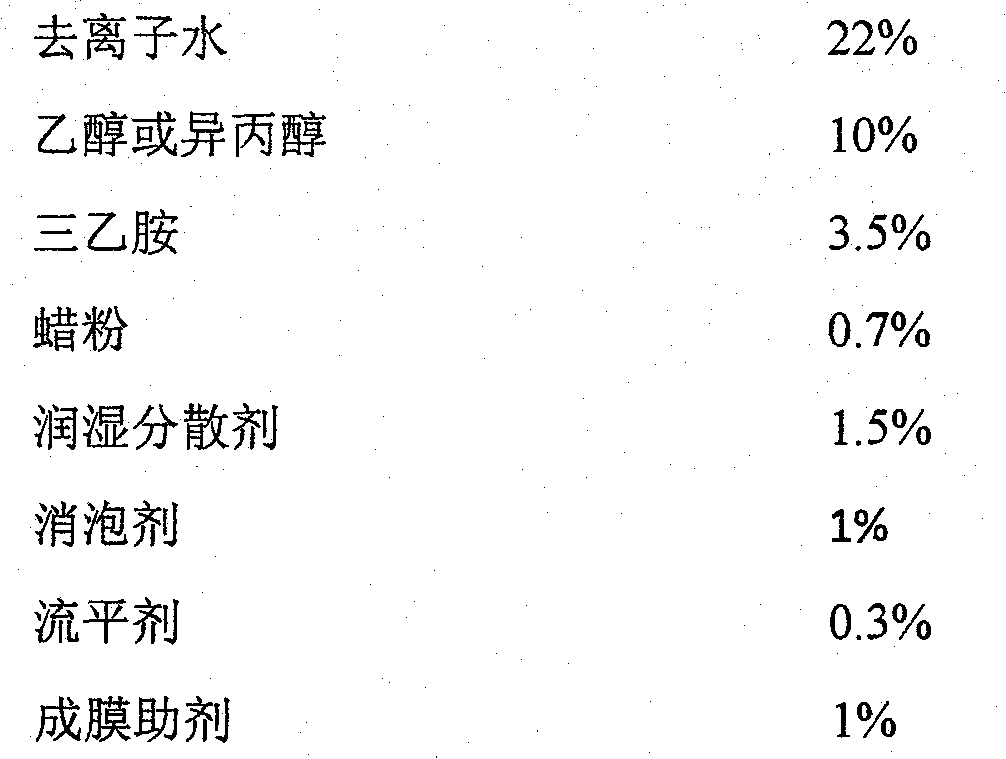

[0063]

[0064] Prepare water-based ink for plastic printing according to the above specific formula data. The wax powder in the formula refers to micronized polyethylene wax; the wetting and dispersing agent in the formula refers to a mixture of high molecular weight nonionic and anionic surfactants; The defoamer in the formula refers to the defoamer for CF 87 water-based ink whose components are mineral hydrocarbons or the defoamer for CF 481 water-based ink whose components are mineral hydrocarbons, silicon dioxide and surfactants; Leveling agent refers to organically modified polydimethylsiloxane solution, such as W-3018 leveling agent for water-based coatings, HX-5600 leveling agent for water-based coatings, etc.; the film-forming aid in the formula refers to high-carbon Alcohol ester organic compounds.

[0065] Silicone modified styrene-acryl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tinctorial strength | aaaaa | aaaaa |

| tinctorial strength | aaaaa | aaaaa |

| tinctorial strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com