Airlift type photo-biologic reactor capable of on-line regulation and control of light intensity

A technology for photobioreactors and reactors, applied in photobioreactors, specific-purpose bioreactors/fermenters, combinations of bioreactors/fermenters, etc. Bioreactors, on-line high-temperature disinfection and sterilization obstacles, etc., to achieve the effect of improving safety, ensuring light time, and simplifying disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

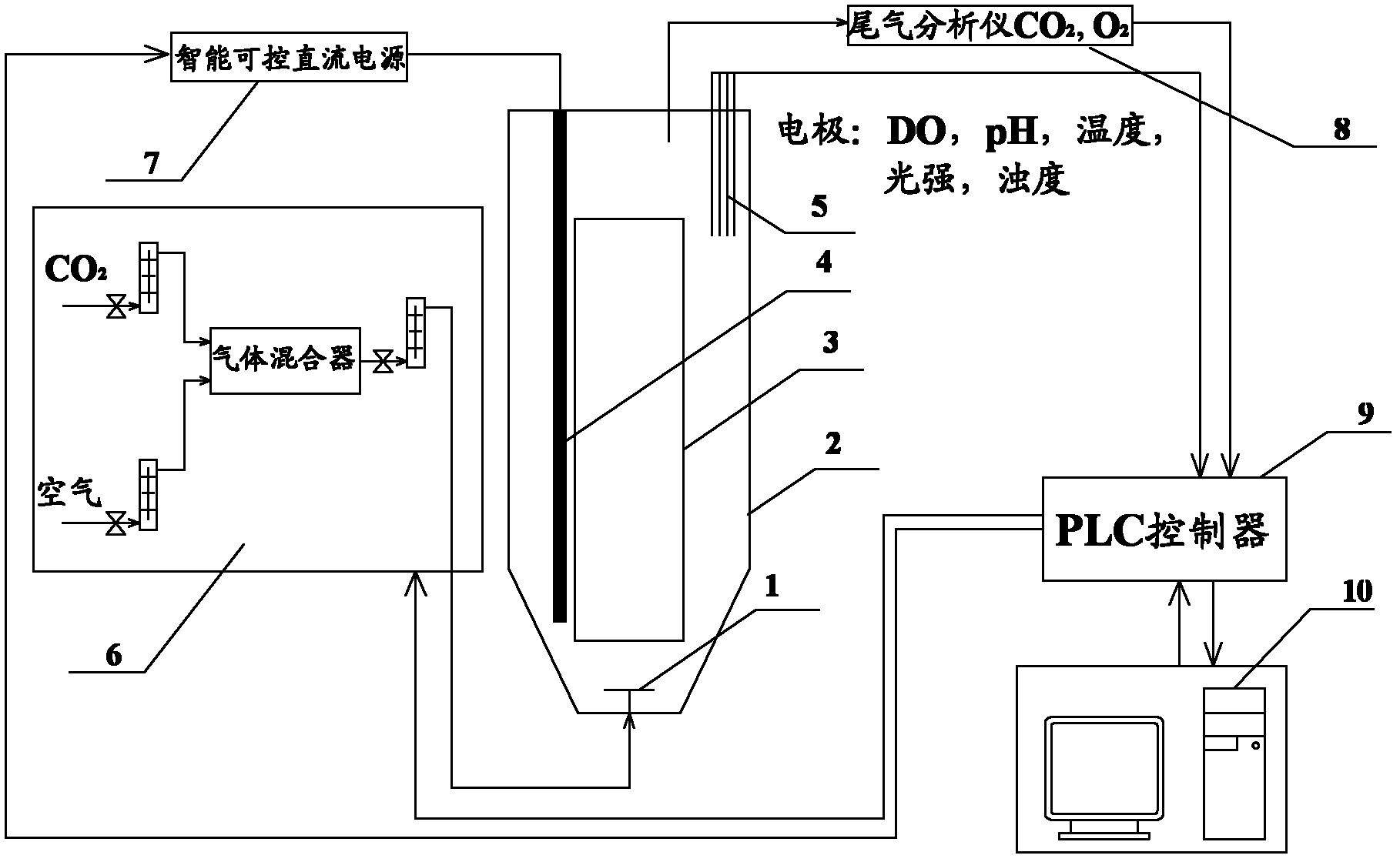

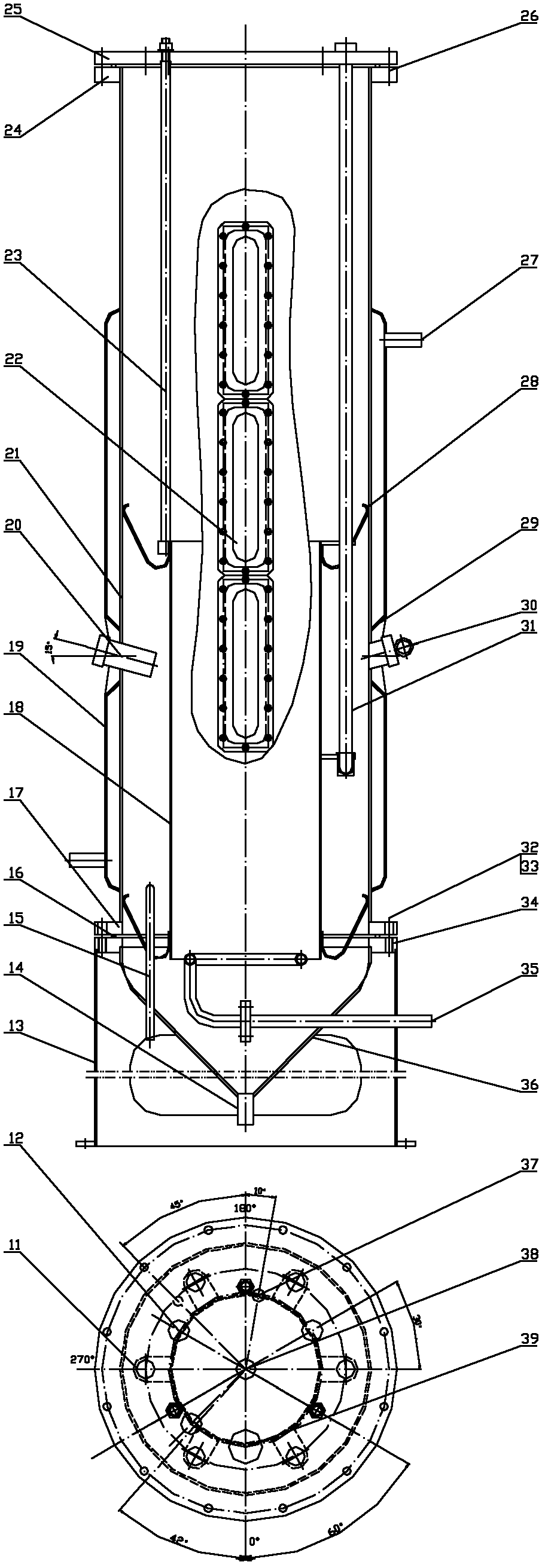

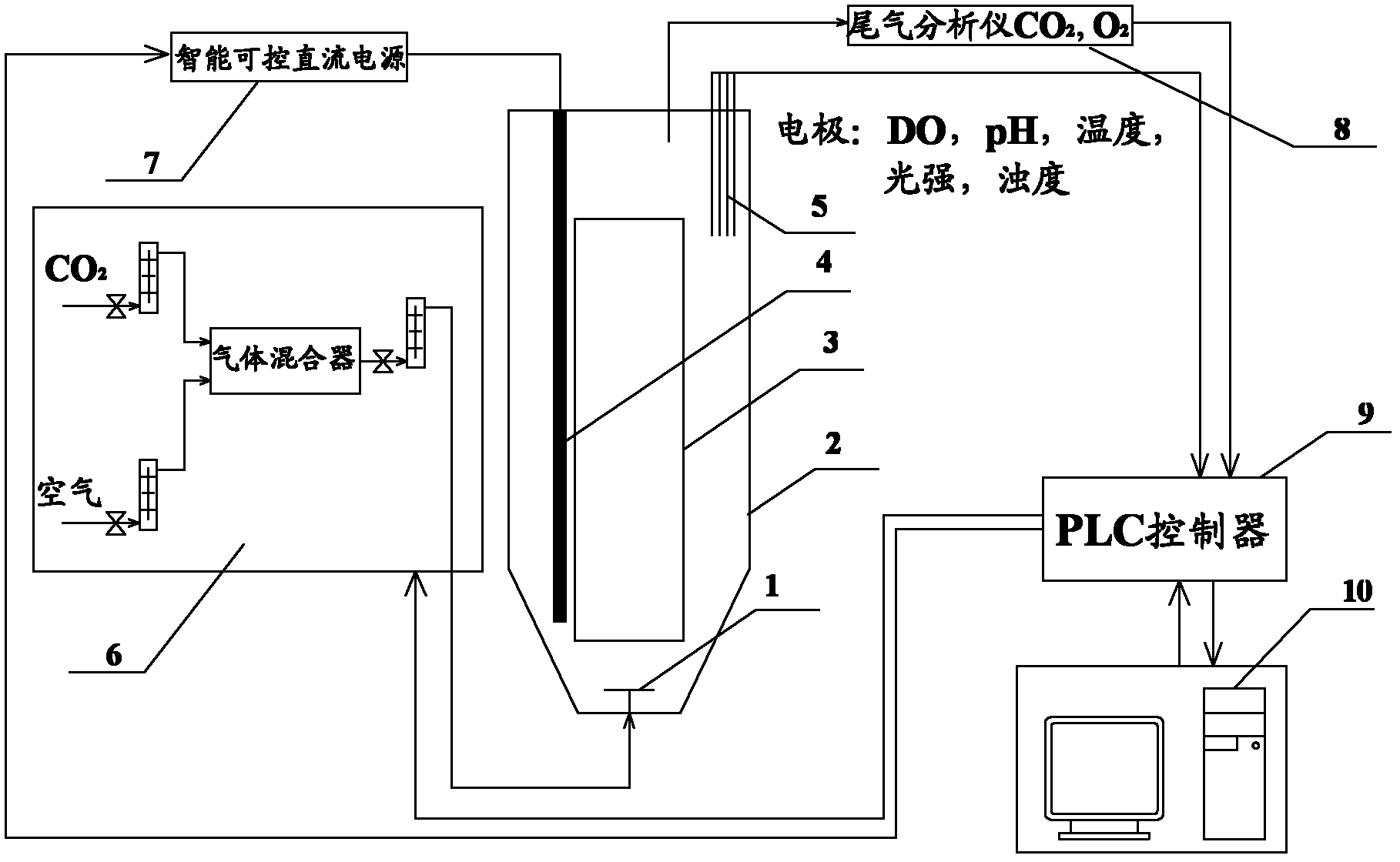

[0048] like figure 1 As shown, an airlift photobioreactor with on-line control of light intensity of the present invention, the device is mainly composed of a gas distributor 1, an airlift reactor main body 2, a built-in guide tube 3, an LED light source 4, and an electrode monitoring system 5. Gas distribution system 6, light control system 7, tail gas analysis system 8, PLC controller 9, and microcomputer system 10.

[0049] The gas distributor 1 is used to pass the air and CO 2 Distributed into uniform fine bubbles into the reactor;

[0050] The main body 2 of the airlift reactor is a stainless steel airlift photobioreactor;

[0051] The built-in guide tube 3 is a cylindrical tube made of stainless steel;

[0052] The LED light source 4 adopts a light bar connected by 0.5W LED lamp beads that can be purchased in the existing market, and each LED light source is composed of four LED light bars;

[0053] The electrode monitoring system 5 is composed of 5 groups of electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com