Method for controllably synthesizing single-crystal WO2 and WO3 nanowire arrays with good field emission characteristics in low temperature and large area

A nanowire array and large-area technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of poor controllability of shape and structure, poor physical properties of products, and high production cost. Achieve the effect of high field emission uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

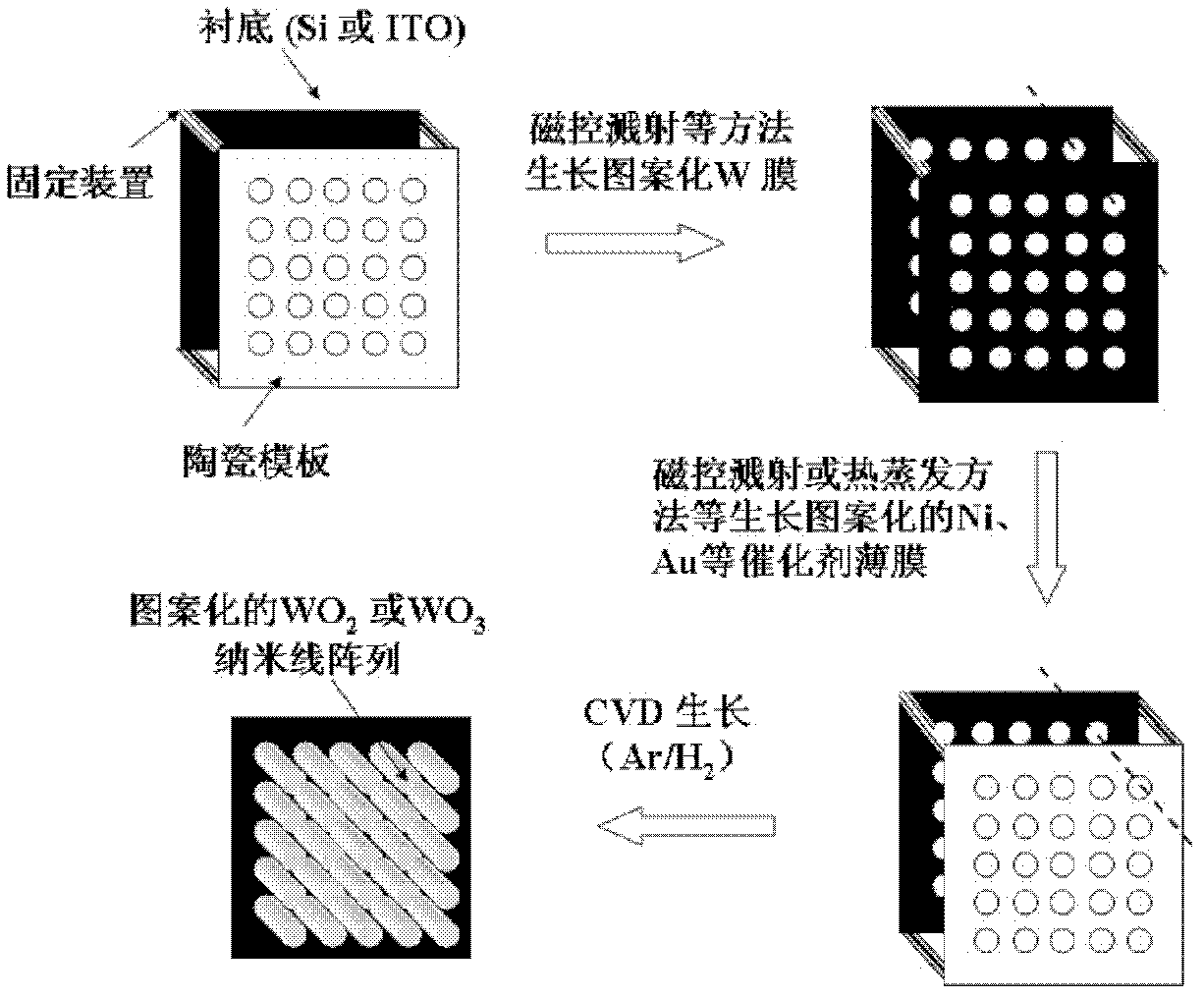

[0043] Example 1: Preparation of Patterned Single Crystal WO by Catalyst Localization Technology at Low Temperature 2 nanowire array

[0044] Using magnetron sputtering technology, using self-made ceramic template device or exposure technology of micro-processing technology, firstly, in the environment of Ar gas, the sputtering power is 300W, the sputtering time is 30min, and a layer of W with a thickness of about 400nm is grown. film, and then sputter-grow a layer of Ni nanoparticle film with a thickness of about 5 nm patterned on the W film.

[0045] The samples with W film and patterned Ni nanoparticle film grown sequentially were put into the CVD system, and the temperature was raised to 400 °C under the protection of Ar gas, and the 2 Insulated in an atmosphere of Ar gas for 1 h, then rapidly heated to 450 °C under the protection of Ar gas, and the growth pressure was 400 Pa. After 2 h of heat preservation, patterned WO was grown on the Si substrate. 2 array of nanowire...

Embodiment 2

[0047] Example 2: Preparation of patterned single crystal WO by catalyst localization technology at low temperature 3 nanowire array

[0048] Using magnetron sputtering technology, using self-made ceramic template device or exposure technology of micro-processing technology, firstly, in the environment of Ar gas, the sputtering power is 300W, the sputtering time is 30min, and a layer of W film with a thickness of about 400nm is grown. , and then a patterned Au nanoparticle film with a thickness of about 3 nm was vacuum evaporated on top of the W film.

[0049] The samples with W thin film and patterned Au nanoparticle thin film grown sequentially were placed in the CVD system, and the temperature was raised to 500 °C under the protection of Ar gas. 2 Insulated in an atmosphere of Ar gas for 1 h, then rapidly heated to 550 °C under the protection of Ar gas, the growth pressure was 8000 Pa, and after 2 h of growth, patterned WO could be grown on the Si substrate. 3 array of na...

Embodiment 3

[0051] Example 3: Using Catalyst Localization Technology to Prepare WO at Different Growth Temperatures 2 Nanowires

[0052] Keeping the argon (Ar) carrier gas flow rate as 200sccm, the reaction pressure as 400Pa, and the reaction time of 2h under the reaction conditions, change the reaction temperature to prepare WO 2 Nanowire array:

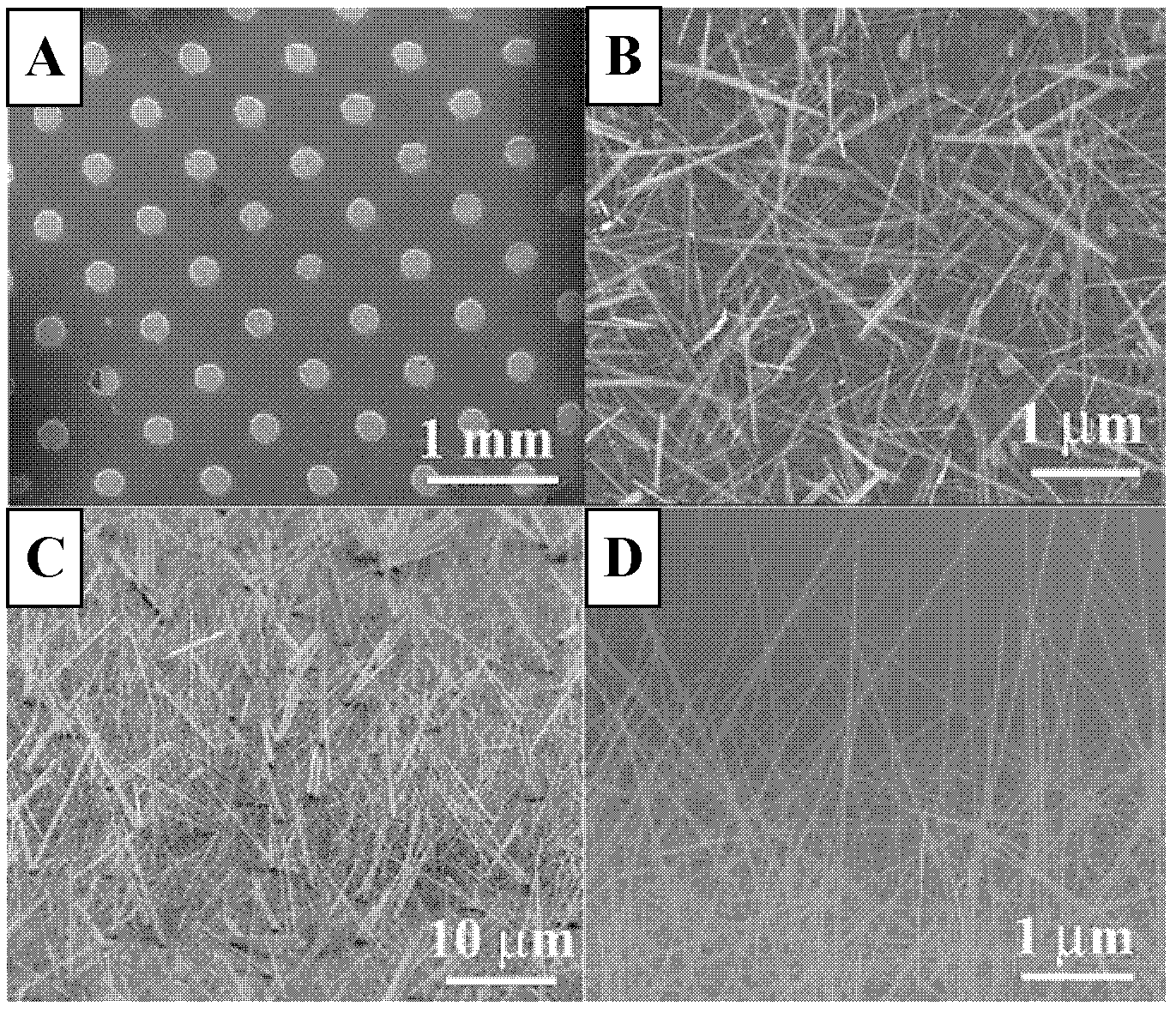

[0053] (1) When the reaction temperature is 550 °C, a higher density WO can be prepared on the Si substrate 2 The nanowire has a length of 2-3μm and a diameter of 40nm, and the shape and diameter of the nanowire are relatively uniform, such as Figure 8 As shown in A

[0054] (2) When the reaction temperature is 600°C, WO 2 The density of the nanowires decreased while the diameter increased to about 60nm, as shown in Figure 8 Shown in B.

[0055] (3) When the reaction temperature is 700°C, WO 2 The diameter of the nanowire increases significantly, and the diameter distribution range is large. Between 40-100nm, the density of the nanowi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com