Method for preparing 5-hydroxymethylfurfural from carbohydrate

A technology of carbohydrates and hydroxymethyl furfural, applied in directions such as organic chemistry, can solve the problems of unfavorable large-scale production of 5-HMF, inability to realize industrialized large-scale production, and high fructose price, and achieves good catalytic effect, low cost, and post-processing. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

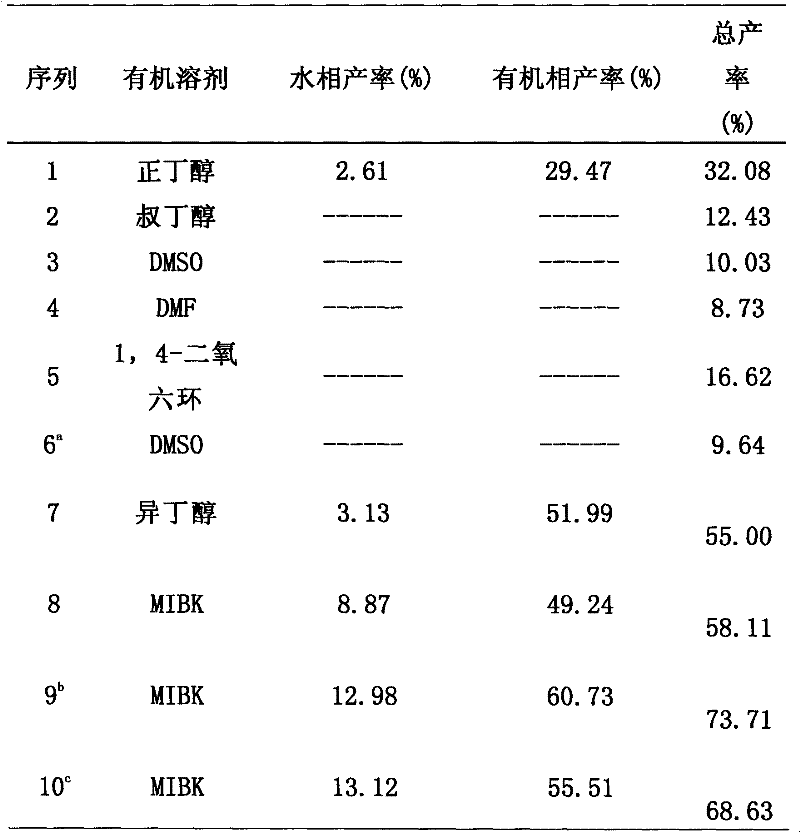

Image

Examples

Embodiment 1

[0019] 0.3000g glucose, 3.0000g [OMIM] BF 4 Ionic liquid, 0.1500g metaphosphoric acid, 1.5000g water, 175°C, reacted for 24h, and the yield of 5-hydroxymethylfurfural determined by high performance liquid chromatography was 55.4%.

Embodiment 2

[0021] 0.3000g fructose, 3.0000g [OMIM] BF 4 Ionic liquid, 0.1500g metaphosphoric acid, 1.5000g water, 175°C, after reaction for 24h, the yield of 5-hydroxymethylfurfural was determined to be 73.8% by high performance liquid chromatography.

Embodiment 3

[0023] 0.3000g sucrose, 3.0000g [OMIM]BF 4 Ionic liquid, 0.1500g metaphosphoric acid, 1.5000g water, 175°C, after reaction for 24h, the yield of 5-hydroxymethylfurfural was determined to be 63.7% by high performance liquid chromatography.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com