Method for preparing binderless ZSM5/beta composite zeolite molecular sieve

A technology of ZSM-5 and composite molecular sieve, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of cumbersome preparation process and achieve simplified preparation process, uniform distribution, and improved The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

[0015] In the preparation process, only one seed crystal of zeolite beta is used.

[0016] Take by weighing 5 grams of white carbon black, 6.5 grams of alumina and 70 grams of beta zeolite (SiO 2 / Al 2 o 3 The molar ratio is 30), add 62.5 grams of silica sol (SiO 2 The mass percentage is 40%) for kneading and molding, and the shaped catalyst is baked at 100° C. for 3 hours.

[0017] 15 grams of triethylamine, 10 grams of ethylenediamine and 10 grams of distilled water were added in advance to the reaction kettle, and 60 grams of the above-mentioned cylindrical product was placed in the reaction kettle and sealed above the porous stainless steel mesh, and then the gas-solid phase was carried out at 120 ° C. 3 days of treatment, 6 days. After the product was taken out, it was washed with distilled water, dried in the air and then calcined at 550°C in an air atmosphere.

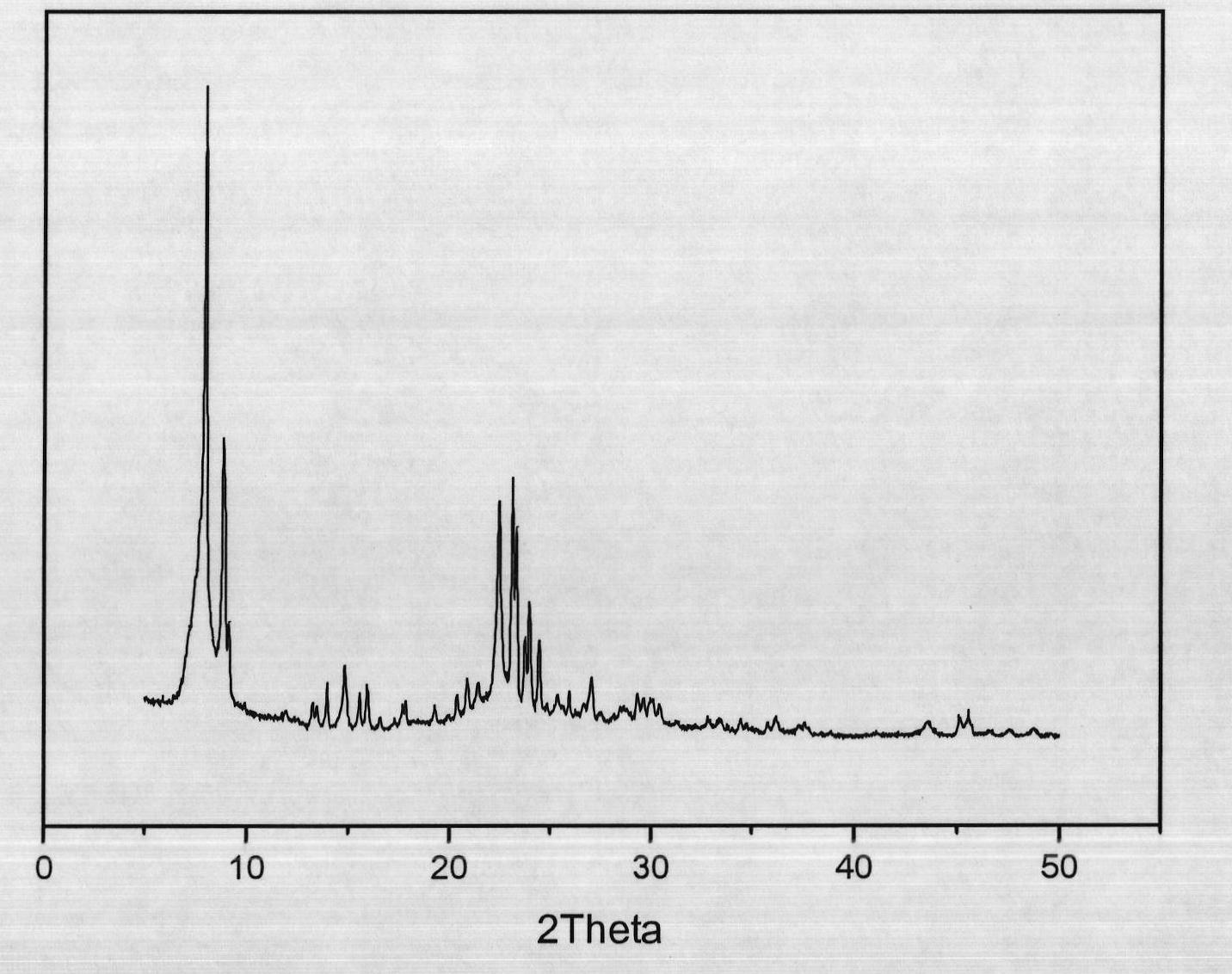

[0018] Process the product XRD pattern of 3 days (see figure 1 ) shows that the product contains the di...

Embodiment 3

[0020] In the preparation process, only one seed crystal of zeolite beta is used.

[0021] Take by weighing 2.8 grams of sodium metaaluminate and 50 grams of beta zeolite (SiO 2 / Al 2 o 3 Molar ratio is 20), add 90 grams of silica sol (SiO 2 The mass percentage is 40%) for kneading and molding, and the shaped catalyst is baked at 100° C. for 3 hours.

[0022] 50 grams of triethylamine and 10 grams of distilled water were pre-added in the reaction kettle, and 60 grams of the above-prepared cylindrical product was placed in the reaction kettle above the porous stainless steel mesh and sealed and then subjected to gas-solid phase treatment at 180° C. for 5 days. After the product was taken out, it was washed with distilled water, dried in the air and then calcined at 550°C in an air atmosphere.

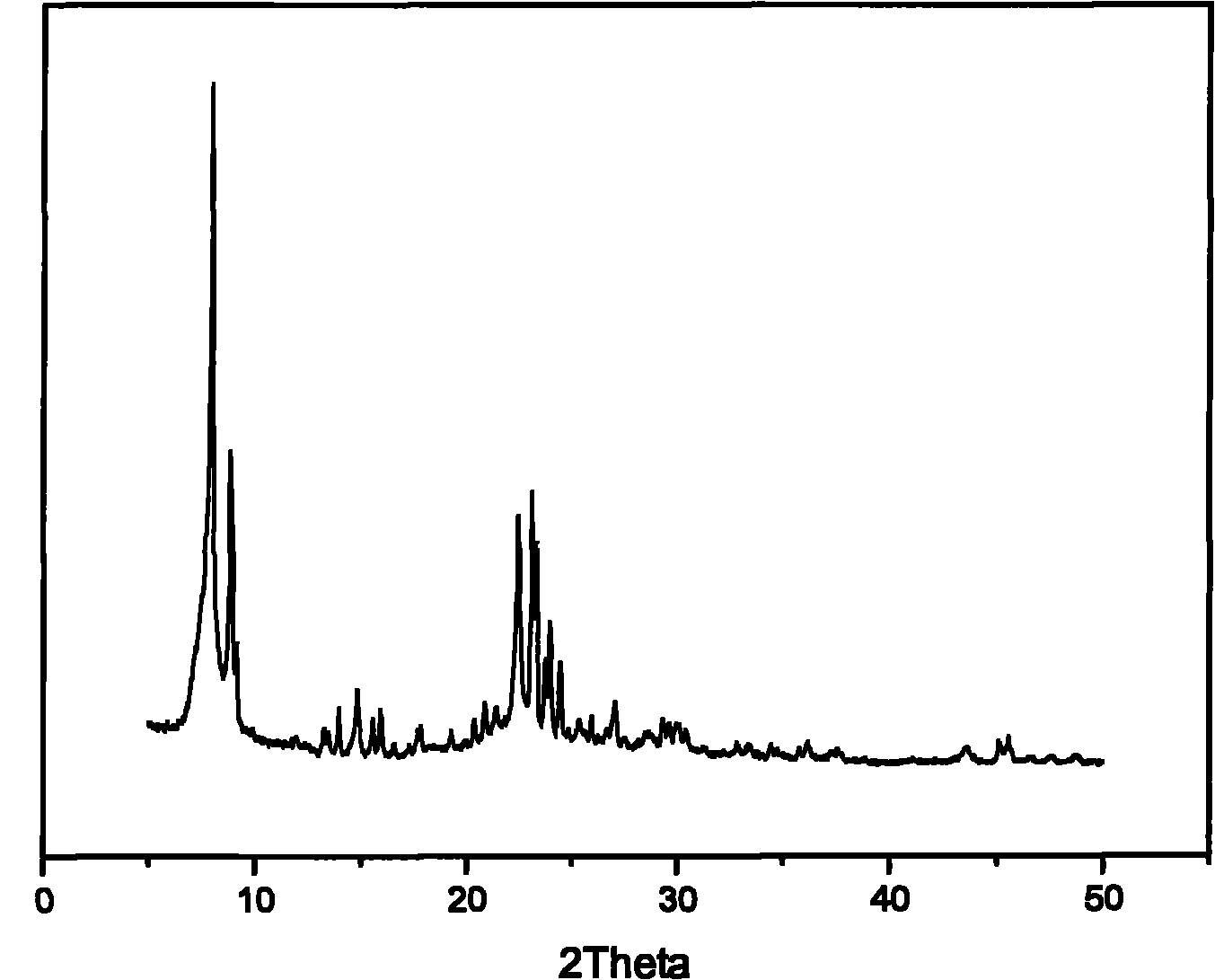

[0023] The XRD pattern of the product treated for 5 days shows that the main diffraction peak of the zeolite beta molecular sieve is smaller than that of the ZSM-5 zeolite molecular ...

Embodiment 4~6

[0025] Take by weighing 120 grams of white carbon black, 4.2 grams of aluminum sulfate and 10 grams of beta zeolite (SiO 2 / Al 2 o 3 The molar ratio is 50), add 175 grams of silica sol (SiO 2 The mass percentage is 40%) for kneading and molding, and the shaped catalyst is baked at 100° C. for 3 hours.

[0026] A mixture of 30 grams of ethylamine and 3 grams of distilled water was added to the reaction kettle in advance, and 20 grams of the above-prepared cylindrical products were placed in the reaction kettle above the porous stainless steel mesh and sealed, and then gas-solid phase treatment was carried out at 100°C respectively 3, 5 ,8 days. After the product was taken out, it was washed with distilled water, dried in the air and then calcined at 550°C in an air atmosphere.

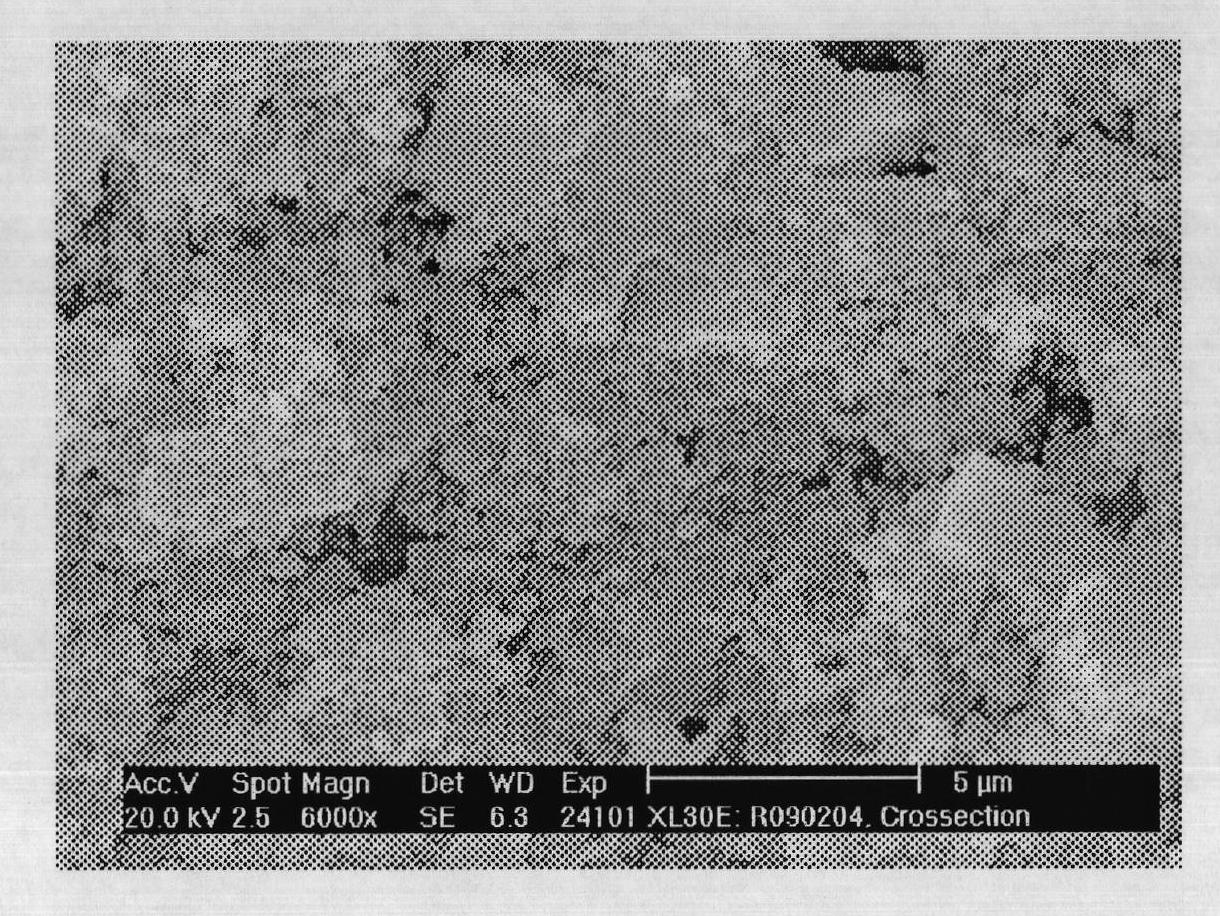

[0027] The XRD patterns of the products of the three examples all contain diffraction peaks of ZSM-5 and zeolite beta, indicating that the products contain both ZSM-5 and zeolite beta; SEM photos sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| surface | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com