High-efficiency anti-magnesium ion oil displacement method

An oil displacement method and magnesium ion technology are applied in the field of high-efficiency anti-magnesium ion oil displacement, which can solve the problems of alkali corrosion, high use concentration and poor oil displacement efficiency in ternary composite flooding, and achieve strong ability to reduce interfacial tension, The effect of high salinity resistance and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

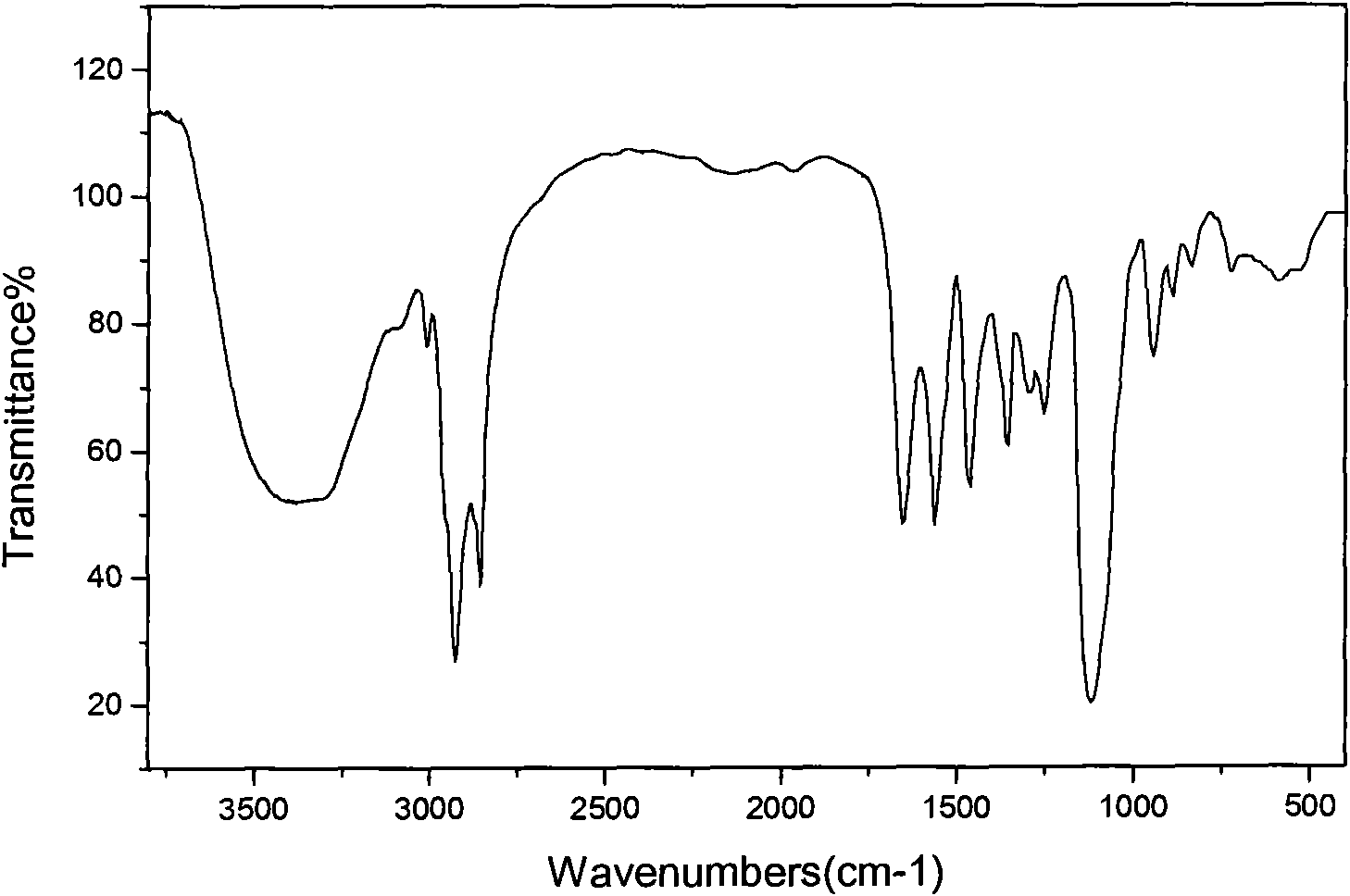

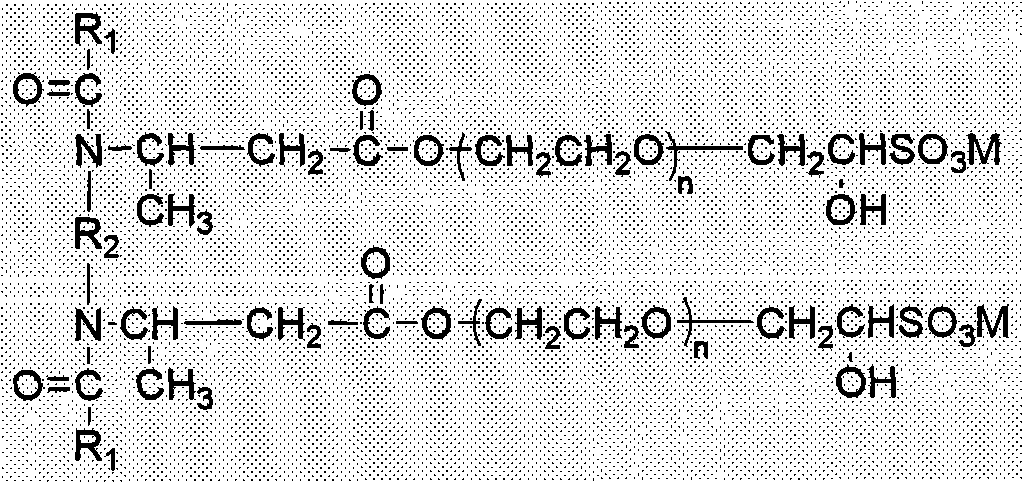

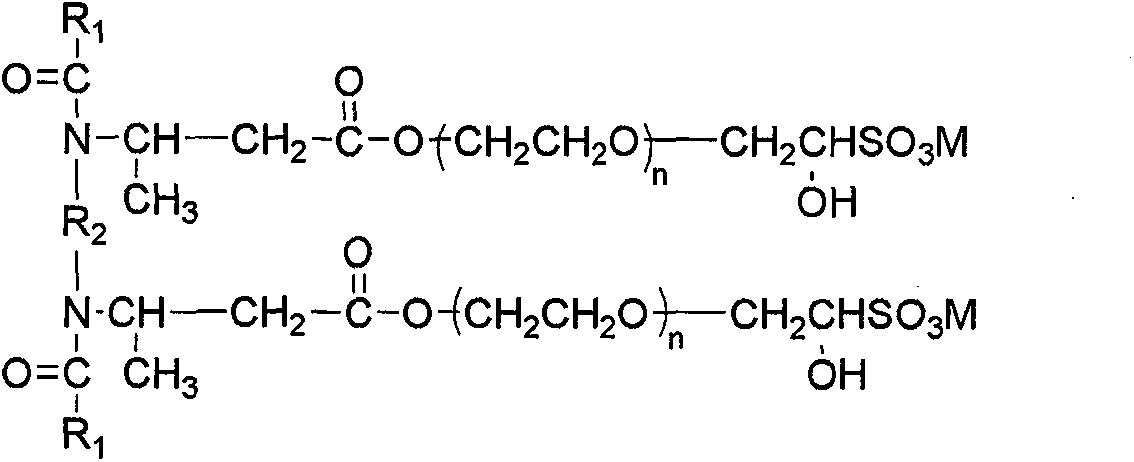

Image

Examples

Embodiment 1

[0034] (a) Synthesis of N, N-dilauroyl ethylenediamine dimethyl propionic acid

[0035] 300 grams (1.5 moles) of lauric acid, 267.8 grams (2.25 moles) of thionyl chloride and 4.5 grams of DMF were added to a 1000-milliliter four-necked flask equipped with a sealed mechanical stirrer, a thermometer, a condenser tube, etc., and reacted at 90 ° C for 3 After one hour, excess thionyl chloride was distilled off under reduced pressure to obtain lauroyl chloride. Add 45.0 grams (0.75 moles) of anhydrous ethylenediamine and 180 grams of 1,4-dioxane to another 2000 ml four-neck flask equipped with a sealed mechanical stirrer, a thermometer, and a condenser tube, heat up to 50° C., and slowly Add 165.0 grams (1.65 moles) of methyl methacrylate dropwise, continue the reaction for 3 hours after dropping, remove unreacted methyl methacrylate and solvent 1,4-dioxane under reduced pressure, and the residue is ethylenediamine dioxane. Methyl methpropionate. Use 50wt% sodium hydroxide to adj...

Embodiment 2

[0043] (a) Synthesis of N, N-dilauroyl hexamethylenediamine dimethylpropionic acid

[0044] With [Example 1] (a), the difference replaces 45.0 grams (0.75 moles) of anhydrous ethylenediamine with 87.0 grams (0.75 moles) of anhydrous hexamethylenediamine, and the rest are the same to obtain N, N-dilauroyl Hexamethylenediamine dimethyl propionic acid 328.6 grams, molar yield 67.2%.

[0045] (b) Synthesis of N,N-dilauroylhexamethylene diamine dimethyl propionate dipolyoxyethylene ether (n=3)

[0046] With [Example 1] (b), the difference is 328.6 grams (0.504 moles) of N, N-dilauroyl hexamethylenediamine dimethyl propionic acid instead of 306.2 grams (0.514 moles) of N, N-didodecanoic acid The consumption of acyl ethylenediamine dimethyl propionic acid and oxirane is 133.1g (3.024 moles), and the consumption of the basic compound of calcium is 7.5 grams to obtain N, N-dilauroyl hexamethylene diamine Dipolyoxyethylene methpropionate (n=3) was 409.5 grams, and the molar yield was ...

Embodiment 3

[0052] (a) Synthesis of N, N-didecanoyl butanediamine dimethylpropionic acid

[0053] With [Example 1] (a), the difference replaces 300.0 grams (1.5 moles) of lauric acid with 261.0 grams (1.5 moles) of capric acid, and replaces 45.0 grams (0.75 grams) of anhydrous butanediamine with 66.0 grams (0.75 moles). mol) anhydrous ethylenediamine, and the rest are the same to obtain 283.3 grams of N, N-didecanoyl butanediamine dimethylpropionic acid, and the molar yield is 66.5%.

[0054] (b) Synthesis of N, N-didecanoyl butanediamine dimethyl propionate dipolyoxyethylene ether (n=3)

[0055] With [Example 1] (b), the difference is 283.3 grams (0.499 moles) of N, N-didecanoyl butanediamine dimethyl propionic acid instead of 306.2 grams (0.514 moles) of N, N-dilauroyl The consumption of ethylenediamine dimethylpropionic acid and oxirane is 131.7g (2.994 moles), and the consumption of the basic compound of calcium is 6.4 grams to obtain N, N-didecanoyl butanediamine dimethyl Dipolyoxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com