Extracting agent for treating dioxin in flying ash and method for extracting dioxin by extracting agent

An extractant and fly ash technology, applied in the field of environmental engineering, can solve the problems of low decomposition efficiency and incomplete elimination of dioxin, and achieve the effect of high processing efficiency, low price and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Sulfonated kerosene with a volume percentage of 80%, n-hexane with a volume percentage of 10% and acetone with a volume percentage of 10% were uniformly mixed to prepare an extractant.

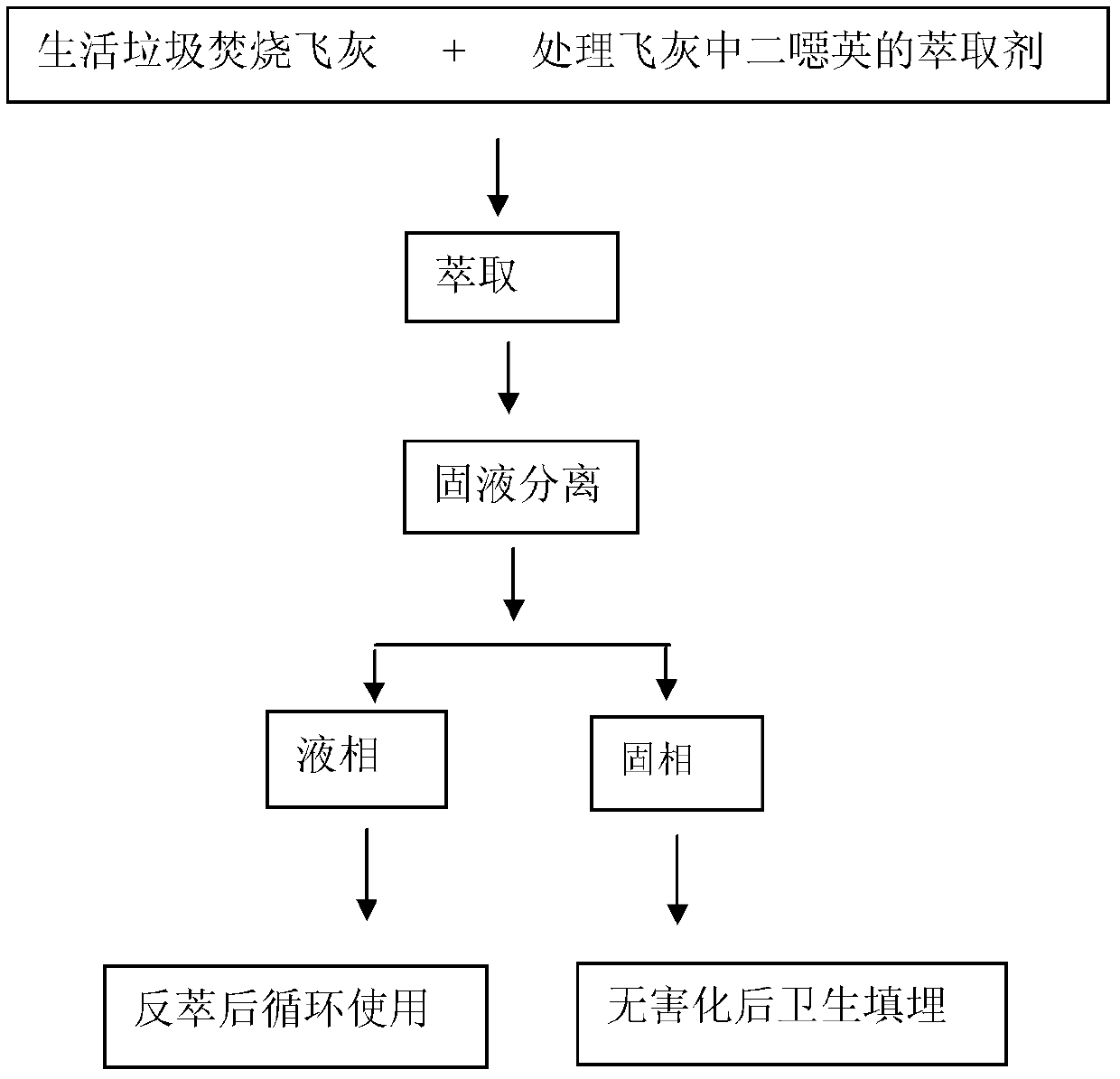

[0029] figure 1 It is a flowchart of a method for extracting dioxins in fly ash with the extractant for treating dioxins in fly ash of the present invention. The prepared extraction agent for treating dioxin in the fly ash and the municipal solid waste incineration fly ash were mixed and extracted according to the mass ratio of 1:1, placed in a stirrer at room temperature and stirred continuously for 12 hours, and then left to stand at room temperature and separated into layers , solid-liquid separation, after static stratification, it is divided into upper and lower layers, the upper layer is liquid phase extractant; the lower layer is solid phase fly ash, the dioxin concentration in fly ash is 2.1-2.7μgTEQ / kg, which is lower than that of domestic waste filling The concentration limit...

Embodiment 2

[0032] Sulfonated kerosene with a volume percentage of 10%, n-hexane with a volume percentage of 50% and acetone with a volume percentage of 40% were uniformly mixed to prepare an extractant.

[0033] The prepared extraction agent for treating dioxin in the fly ash and the municipal solid waste incineration fly ash were mixed and extracted according to a mass ratio of 3:1, placed in a stirrer at room temperature and stirred continuously for 24 hours, and then left to stand at room temperature and separated into layers , solid-liquid separation, after static stratification, it is divided into upper and lower layers, the upper layer is the liquid phase extractant, the lower layer is the solid phase fly ash, the dioxin concentration in the fly ash is 1.7-2.2μgTEQ / kg, which is lower than that of domestic waste filling Concentration limits of fly ash toxic equivalent in landfill pollution control standards. Among them: after the extractant is repeatedly extracted and reaches satura...

Embodiment 3

[0035] Sulfonated kerosene with a volume percentage of 45%, n-hexane with a volume percentage of 30% and acetone with a volume percentage of 25% were uniformly mixed to prepare an extractant.

[0036] The prepared extraction agent for treating dioxin in the fly ash and the municipal solid waste incineration fly ash were mixed and extracted according to the mass ratio of 2:1, placed in a stirrer at room temperature and stirred continuously for 24 hours, and then left to stand at room temperature and separated into layers , solid-liquid separation, after static stratification, it is divided into upper and lower layers, the upper layer is the liquid phase extractant, the lower layer is the solid phase fly ash, the dioxin concentration in the fly ash is 2.0-2.5μgTEQ / kg, which is lower than Concentration limits of fly ash toxic equivalent in landfill pollution control standards. Among them: after the extractant is repeatedly extracted and reaches saturation, it can be back-extracte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com