Powdered rock phosphate oxygen-enriched binder

A technology of phosphate rock powder and binder, which is applied in the direction of phosphate material treatment, fertilizer mixture, fertilization device, etc., can solve the problems of restricting the development of phosphorus chemical industry and difficult to effectively utilize and reflect resource advantages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

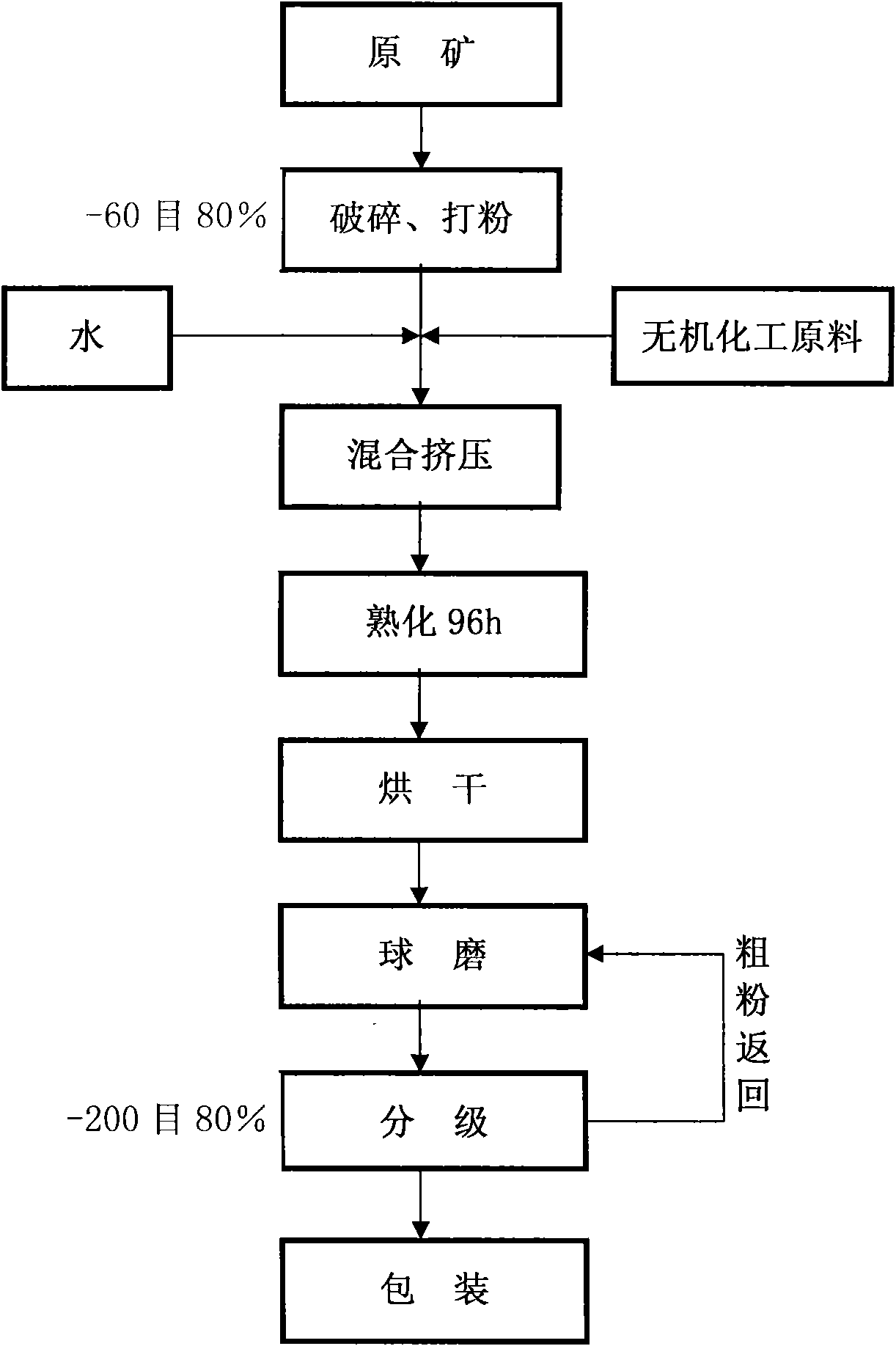

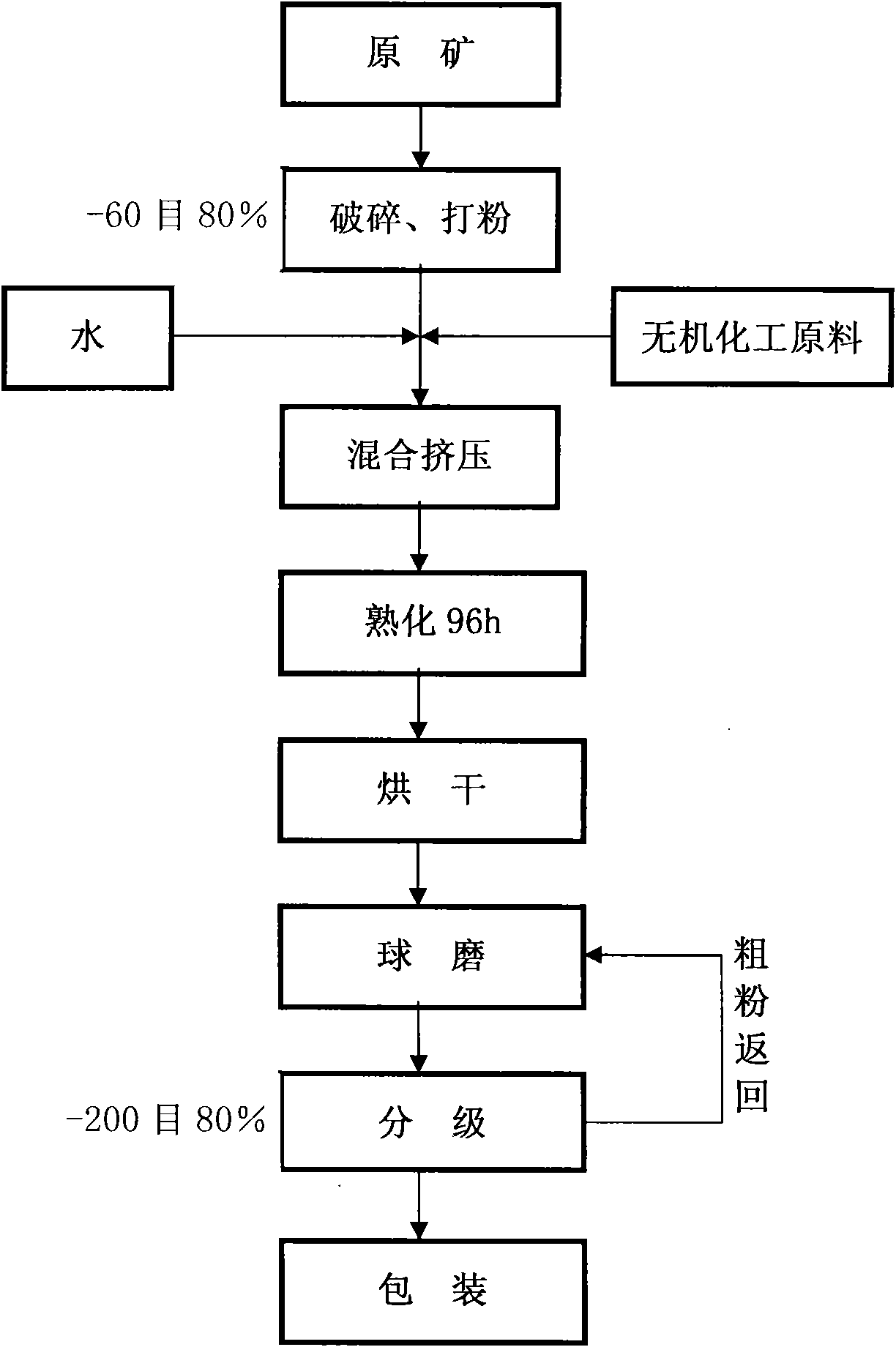

[0009] The technical solution will be specifically described as an embodiment in conjunction with the accompanying drawings.

[0010] refer to figure 1 , the production of phosphate rock powder oxygen-enriched binder is proportioned, and the raw ore undergoes mechanical mixing-crushing (powdering)-sodium modification (mixed extrusion)-drying-ball milling-cyclone classification filtration-packaging and other technological processes processed. The specific production process is to take 3%-5% of rare earth elements containing copper and barium, 5%-10% of sodium chloride, 5%-10% of calcium chloride, 5%-10% of zinc chloride, and sodium carbonate according to the weight percentage. 5%-10%, Potassium Carbonate 2~11%, crush and mix evenly, add sufficient amount of water and the powdery materials of the aforementioned six kinds of inorganic chemical raw materials and stir evenly to make a medicament with a concentration of 20-45% for later use, and then press the medicament: Montmori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com