One-step continuous granulation preparation method for water absorbent granule

A water-absorbing agent and granule technology, which is applied in the field of one-step continuous granulation of water-absorbing agent granules, can solve the problems of uneven particle size and long drying time, achieve uniform particle size distribution, increase particle size, and facilitate process scale-up Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

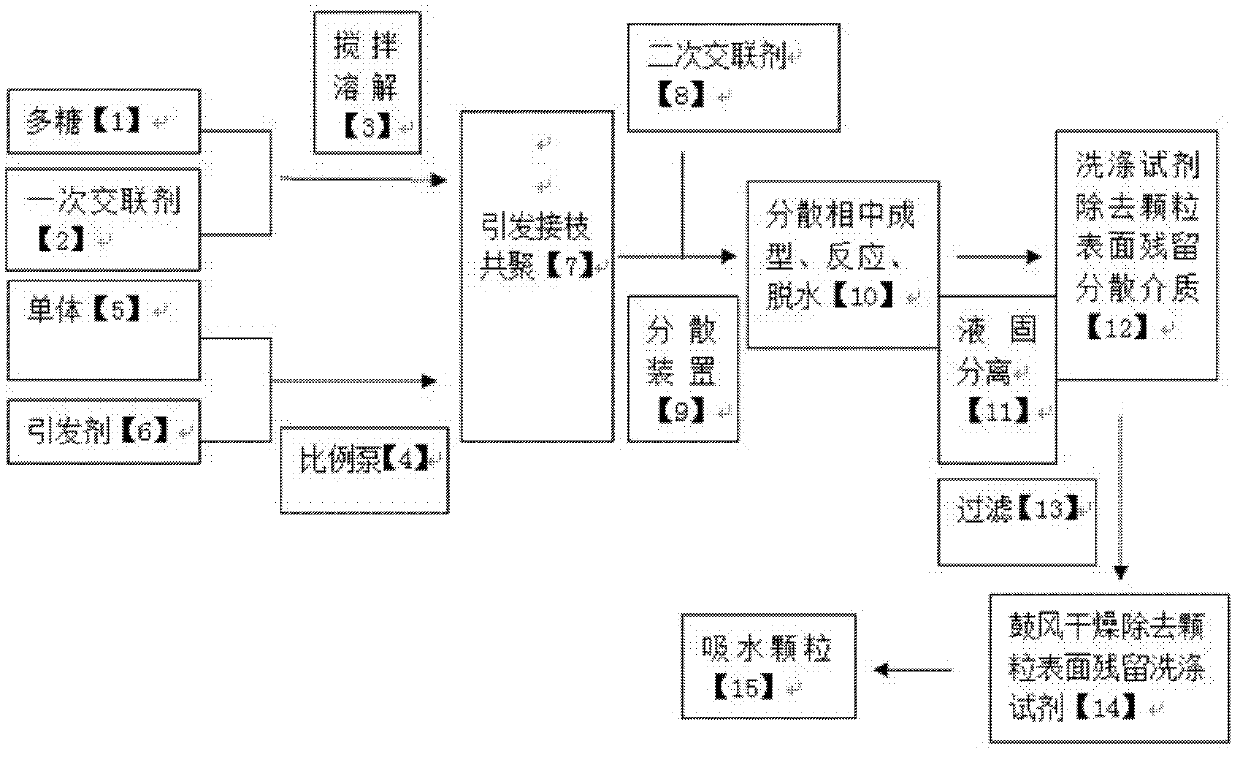

Method used

Image

Examples

example 1

[0049] A kind of water absorbing agent particles, which are composed of the following materials with the following mass ratios:

[0050] Raw material mass ratio%

[0051] Polysaccharide Konjac Glucomannan 0.9%

[0052] Xanthan gum 0.1%

[0053] Monomer acrylic acid 98.14%

[0054] Initiator Potassium persulfate 0.1%

[0055] Crosslinking agent Primary crosslinking agent Alumina 0.6%

[0056] Secondary crosslinking agent N, N-methylene bisacrylamide 0.16%

[0057] Note: The monomer is a monomer compound (sodium acrylate) partially neutralized by a neutralizing alkali (sodium hydroxide), and the degree of neutralization is 80 mol% (that is, the molar ratio of sodium acrylate to acrylic acid in the monomer is 80:20);

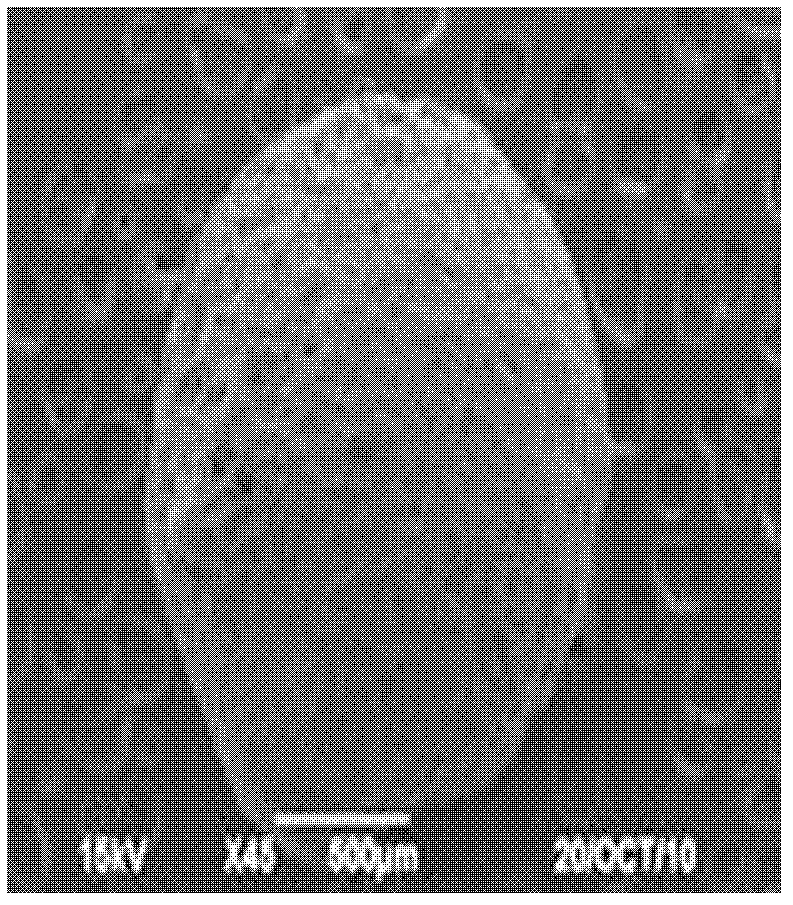

[0058] Obtained as a granular product with a particle size of 2.5mm, the product has a water absorption rate of 1000 times for pure water and 90 times for physiological saline.

[0059] A preparation method of one-step continuous granulation of water-absorbing age...

example 2

[0065] A kind of water absorbing agent particles, which are composed of raw materials with the following mass ratios:

[0066] Raw material mass ratio%

[0067] Polysaccharide starch 2%

[0068] Monomer acrylic acid 95.8%

[0069] Initiator Ammonium persulfate 0.15%

[0070] Crosslinking agent Primary crosslinking agent N,N-methylenebisacrylamide 0.05%

[0071] Secondary crosslinking agent Epichlorohydrin 2%

[0072] Note: The monomer is a monomer compound (potassium acrylate) partially neutralized by a neutralizing base (potassium hydroxide), and the neutralization degree is 50 mol% (that is, the molar ratio of potassium acrylate to acrylic acid in the monomer is 50:50);

[0073] A granular product with a particle size of 1.5 mm was obtained. The product has a water absorption rate of 400 times for pure water and 50 times for normal saline.

[0074] A preparation method for one-step continuous granulation of water absorbing agent particles, which comprises the following steps:

[0...

example 3

[0080] A kind of water absorbing agent particles, which are composed of raw materials with the following mass ratios:

[0081] Raw material mass ratio%

[0082] Polysaccharides Seaweed 9%

[0083] Monomer Methacrylic acid 77.5%

[0084] Styrene sulfonic acid 8.75%

[0085] Initiator sodium persulfate 0.15%

[0086] Crosslinking agent Primary crosslinking agent Epichlorohydrin 0.1%

[0087] Secondary crosslinking agent 4.5% alumina

[0088] Note: The monomer is a monomer compound (ammonium methacrylate, ammonium styrene sulfonate) partially neutralized by neutralizing alkali (aqueous ammonia), and the degree of neutralization is 70 mol% (that is, ammonium methacrylate, methacrylic acid in the monomer The molar ratio of styrene sulfonic acid is 70:30, and the molar ratio of ammonium styrene sulfonate to styrene sulfonic acid is 70:30);

[0089] A granular product with a particle size of 3 mm was obtained. The product absorbs 600 times of pure water and 70 times of normal sal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com