Loaded metal hydrogenation catalyst, its preparation method and application in ethylene glycol preparation

A hydrogenation catalyst, metal catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve problems such as unindustrialization, and achieve the effect of high mechanical strength and high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 Ni-Cu-La / SiC-C catalyst

[0023] 1. Polymer / SiO2 2 Preparation of spherical complexes:

[0024] Dissolve 2.4g of cetyltrimethylammonium chloride in 20ml of deionized water, then add 9.0g of tetraethyl silicate, store at 35°C for 24 hours, cool to 5°C, and dissolve metadichloride Add 5ml of ethylene (25wt%) and azobisisoheptanonitrile (1.5wt%) toluene solution directly, stir rapidly, heat up to 40°C and polymerize for 24 hours, thus obtaining polymer / SiO 2 spherical complexes;

[0025] 2. Preparation of SiC / C spherical molecular sieve:

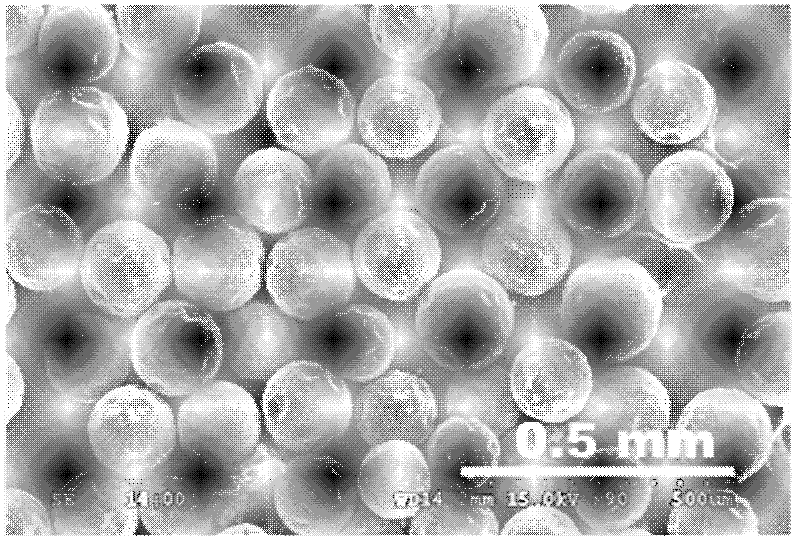

[0026] Polymer / SiO 2 The spherical composite is carbonized by temperature programming in an argon gas flow. The carbonization temperature is 150°C for 3 hours; SiC / C spherical molecular sieves are obtained, the shape is as figure 1 shown.

[0027] 3. Impregnation aging of SiC / C spherical molecular sieve:

[0028] Soak the SiC / C spherical molecular sieve with 30% nitric acid for 24h, then wash it with deionized water ...

Embodiment 2

[0030] Embodiment 2 Preparation of Ni-Cu-Zn-La / SiC-C catalyst:

[0031] Immersion aging of SiC / C spherical molecular sieves: SiC / C spherical molecular sieves were treated with 30% nitric acid overnight, then washed with deionized water and dried in vacuum. Take Ni(NO 3 ) 2 , Cu(NO 3 ) 2 , Zn(NO 3 ) 2 , La(NO 3 ) 3 and nitrilotriacetic acid to form a methanol solution composed of (Ni: 1.5wt%, Cu: 0.5wt%, Zn: 0.5wt%, La: 0.5wt%, nitrilotriacetic acid: 1.5wt%), and then use SiC / C spherical molecular sieve impregnated, dried, heated to 150°C for 3 hours in the air, and activated with hydrogen at 350°C for 3 hours to obtain a supported metal hydrogenation catalyst.

[0032] In a 100ml autoclave, use methanol as a solvent, add methyl oxalate or glycolic acid and 1.5g of catalyst, the reaction hydrogen pressure is 5.0MPa, the reaction temperature is 150-220 ° C, and the progress of the reaction is monitored by gas chromatography. The conversion rate reaches 95%, and the sel...

Embodiment

[0034] Embodiment 3Ni-Co-Zn-La / SiC-C catalyst:

[0035]Immersion aging of SiC / C spherical molecular sieves: SiC / C spherical molecular sieves were treated with 30% nitric acid, washed with deionized water, and dried in vacuum. Take Ni(NO 3 ) 2 , Co(NO 3 ) 2 , Zn(NO 3 ) 2 , La(NO 3 ) 3 and nitrilotriacetic acid to form a methanol solution composed of (Ni: 1.5wt%, Co: 0.5wt%, Zn: 0.5wt%, La: 0.5wt%, nitrilotriacetic acid: 1.5wt%), and then use SiC / C spherical molecular sieve impregnated, dried, heated to 150°C for 3 hours in the air, and activated with hydrogen at 350°C for 3 hours to obtain a supported metal hydrogenation catalyst.

[0036] In a 100ml autoclave, use methanol as a solvent, add methyl oxalate or glycolic acid and 1.5g of catalyst, the reaction hydrogen pressure is about 5.0MPa, the reaction temperature is Si0-220°C, and the progress of the reaction is monitored by gas chromatography. The conversion rate of the product reaches 98%, and the selectivity to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com