Carbon-layer-coated nano iron having butterfly wing microscopic structure and preparation method thereof

A nano-scale, butterfly-wing technology, applied in the field of nano-scale iron and its preparation, can solve problems such as unreported, and achieve the effects of strong chemical stability, excellent magnetic properties, stable and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

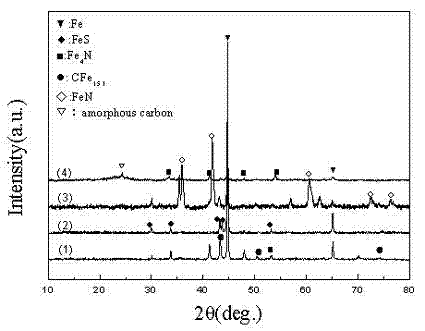

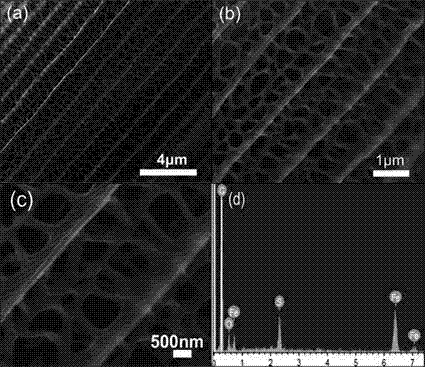

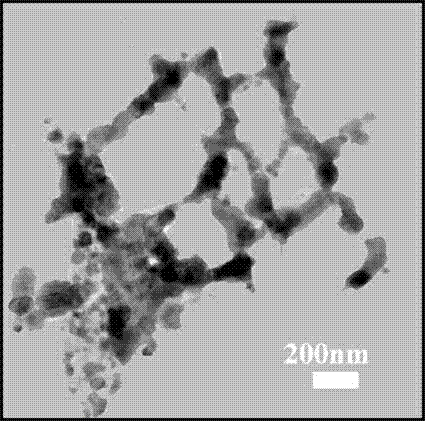

Embodiment 1

[0042] The wings of the different-shaped purple butterfly were selected as the biological template and the raw material for the reaction. First, the butterfly wings were soaked in absolute ethanol for 3 hours to remove the pigment and other alcohol-soluble impurities in the butterfly wings; 20% HCl solution for 3 hours, the purpose is to remove the inorganic salt in the butterfly template that is not easy to decompose, and the components that are not easily removed by sintering, and reduce the impurity content of the final product; after washing, put in a NaOH solution with a mass fraction of 1%. Treated for 12 hours in the middle to expose more amino and hydroxyl groups to improve the adsorption of metal ions; after treatment, take it out and wash it with distilled water for 3 times; then immerse it in saturated Fe(AC) 2 Solution, let stand for 24h. Take it out, wash it three times with distilled water, and put it in a drying oven at 40 °C for 2 h. The dried butterfly wings ...

Embodiment 2

[0045] The wings of Papilio paris were selected as the biological template and reaction raw material. Firstly, the butterfly wings were soaked in absolute ethanol for 0.5h to remove the pigment and other alcohol-soluble impurities in the butterfly wings; then the butterfly wings were immersed in the volume HCl solution with a fraction of 1% for 0.5h, the purpose is to remove the inorganic salt in the butterfly template, which is not easy to decompose, and the components that are not easy to be removed by sintering, and reduce the impurity content of the final product; after washing, put the mass fraction of 40% The NaOH solution was treated for 1h to expose more amino and hydroxyl groups to improve the adsorption of metal ions; after treatment, take it out and wash it with distilled water for 3 times; then immerse it in 1% FeSO 4 solution, let it stand for 4h. Take it out, wash it three times with distilled water, and put it in a drying oven at 40 °C for 2 h. The dried butter...

Embodiment 3

[0048] The wings of the different-shaped purple butterfly were selected as the biological template and the raw material for the reaction. First, the butterfly wings were soaked in absolute ethanol for 3 hours to remove the pigment and other alcohol-soluble impurities in the butterfly wings; 20% HCl solution for 3 hours, the purpose is to remove the inorganic salt in the butterfly template that is not easy to decompose, and the components that are not easily removed by sintering, and reduce the impurity content of the final product; after washing, put in a NaOH solution with a mass fraction of 40% Treated for 12 hours in the middle to expose more amino and hydroxyl groups to improve the adsorption of metal ions; after treatment, take it out and wash it with distilled water for 3 times; then immerse it in 30% Fe(NO 3 ) 3 Solution, let stand for 12h. Take it out, wash it three times with distilled water, and put it in a drying oven at 40 °C for 2 h. The dried butterfly wings ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com