Inorganic-organic slow-acting fertilizer suitable for landscaping nursery stocks and preparation method and application thereof

A landscaping and long-acting fertilizer technology, applied in the field of fertilizer production, can solve the problems of not being able to meet the demand well, the fertilizer efficiency is short, and the fertilization cost is increased, and the effects of improving the growth environment of seedlings, stable fertilizer efficiency, and reducing the number of fertilization and application are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

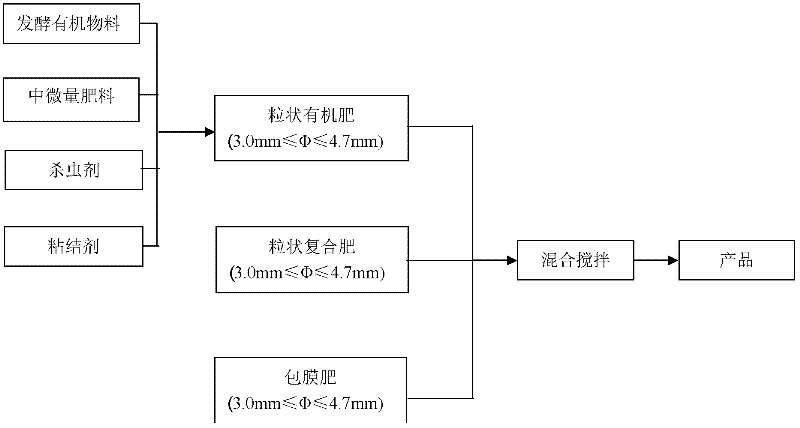

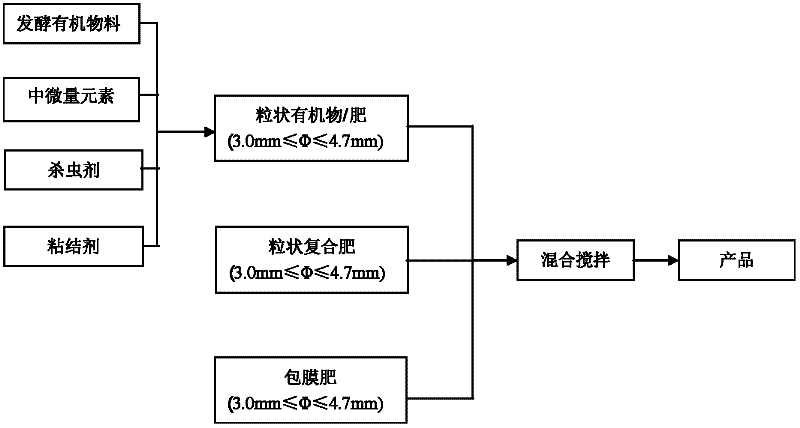

[0044] A kind of preparation method that is applicable to the organic-inorganic long-acting fertilizer of landscaping nursery stock, comprises the following steps (as figure 1 shown):

[0045] (1) Cow dung (water content percentage is 80%) accounting for 60% of the mass of fermented organic material and inorganic conditioner (composed of fly ash and phosphate rock powder) accounting for 12% of the mass of fermented organic material, accounting for 12% of the mass of fermented organic material The organic conditioner (composed of mushroom slag and rice bran) with a mass of 26% and the yeast waste liquid accounting for 2% of the mass of fermented organic materials are uniformly mixed, and composted according to the initial pH value of 6.5 and the mass ratio of carbon to nitrogen of 25:1; when the compost mixture When the moisture content drops to 44%, the compost mixture is packed into the compost reactor, and stirring and forced ventilation are set so that the oxygen content in...

Embodiment 2

[0049] A kind of preparation method that is applicable to the organic-inorganic long-acting fertilizer of landscaping nursery stock, comprises the following steps (as figure 1 shown):

[0050] (1) The compost main material (the mixture of cow dung, chicken manure and pig manure; the water mass percentage is 70%) accounting for 75% of the fermented organic material quality and the inorganic conditioner (composed of 6% of the fermented organic material quality) gypsum powder and sulfur), an organic conditioner (composed of straw and humic acid) accounting for 15% of the mass of fermented organic material, and a decomposing accelerator (composed of distiller's grains and molasses) accounting for 4% of the mass of fermented organic material. Compost with a pH value of 7.5 and a mass ratio of carbon to nitrogen of 35:1; when the moisture content of the compost mixture drops to 46%, put the compost mixture into the compost reactor, set stirring and forced ventilation to make the oxy...

Embodiment 3

[0054] A kind of preparation method that is applicable to the organic-inorganic long-acting fertilizer of landscaping nursery stock, comprises the following steps (as figure 1 shown):

[0055] (1) The compost main material (the mixture of cow dung, chicken manure and pig manure; the water mass percentage is 85%) accounting for 64% of the fermented organic material quality and the inorganic conditioner (composed of 10% of the fermented organic material quality) Meadow soil and peat soil), an organic conditioner (composed of mushroom slag, straw and molasses) accounting for 20% of the mass of fermented organic materials, a decomposing accelerator (composed of monosodium glutamate waste liquid and granulated sugar) accounting for 6% of the mass of fermented organic materials ) uniformly mixed, composting according to initial pH value 5.5, carbon-nitrogen mass ratio 20: 1; In the reactor, the oxygen content is 5%, the temperature is 55 ° C, and the VT-1000 bacterial agent (produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com