Preparation method of guanidine derivative creatine hydrochloride

A technology for creatine hydrochloride and derivatives, which is applied in the field of preparation of guanidino derivative creatine hydrochloride, can solve the problems of harsh process requirements, difficult post-processing, impact on the environment, etc., and achieves simple and easy operation, The effect is stable and reliable, and the operation is simple and easy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

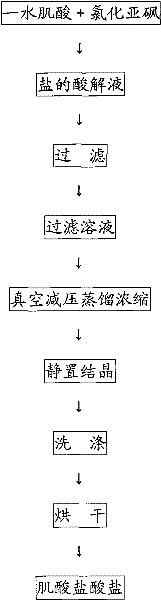

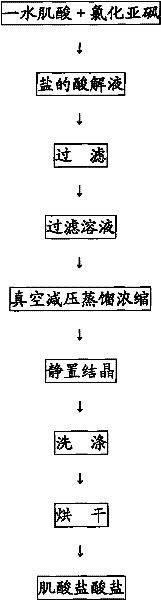

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the accompanying drawings:

[0025] A preparation method of creatine hydrochloride, a guanidinium derivative, using creatine monohydrate as raw material, using sulfur oxychloride for acid hydrolysis, and the creatine monohydrate and sulfur oxychloride are carried out at a temperature of 25-35°C Acid hydrolysis into salt, the filtered solution filtered by acid hydrolysis into salt is concentrated by vacuum distillation and concentrated, and then crystallized on standing, and the standing crystals are washed in the state of solvent suction filtration, and the washed standing The crystals are dried until the water content is less than 1% to obtain the guanidine derivative creatine hydrochloride product.

[0026] In the preparation method of the guanidine derivative creatine hydrochloride, the weight ratio of creatine monohydrate to thionyl chloride is 1:1.25-...

specific Embodiment approach 2

[0034] Carry out by specific implementation mode one, just:

[0035]1. Salt formation: Add 500Kg of 97-99% thionyl chloride to a 1000-liter reactor, turn on the stirring and micro-vacuum state, and slowly add 400Kg of creatine monohydrate, creatine The material will slowly dissolve. After the material is added, stir until it becomes clear. The pH value of the liquid should be 0.5-1. If it is too low, add a small amount of thionyl chloride until the pH value is between 0.5-1 and then at 25 At -30°C, keep warm for 5-6 hours.

[0036] 2. Filtration and concentration: the above-mentioned heat preservation liquid is press-filtered into another clean 1000-liter reactor to remove trace impurities and insoluble matter;

[0037] ①. Heat hot water at 50-60°C in the jacket of the reaction kettle, and keep the temperature in the kettle below 40°C for high-vacuum vacuum distillation to remove thionyl chloride. After a small amount of crystals appear in the reaction kettle, stop the concen...

specific Embodiment approach 3

[0043] On the basis of the specific implementation of the specific implementation modes 1 and 2, the specific implementation of multiple and repeated reductions and expansions of various multiples is carried out in proportion, so that the present invention has a principle test, a small-scale test, and a medium-scale test. The solid foundation of , expanded test and productive test has achieved the expected good effect, has practical operability, and has a wide range of popularization and application value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com