Preparation method for high temperature-resistant automobile brake lining

A technology for automobile braking and high temperature resistance, applied in the field of composite friction materials, can solve problems such as unsatisfactory high temperature resistance effect, and achieve the effects of good thermal recession resistance, low wear rate, and improved high temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

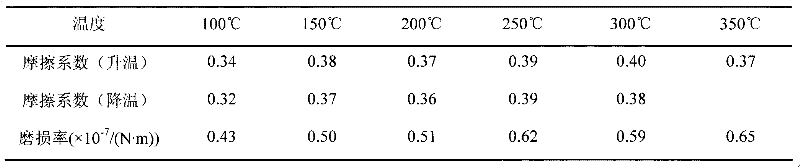

Image

Examples

preparation example Construction

[0022] The invention provides a method for preparing a high-temperature-resistant automobile brake lining, which consists of organic binder: phenolic resin, reinforcement: inorganic fiber and cellulose fiber, friction performance regulator: graphite, molybdenum disulfide, aluminum oxide, Self-made phase change material and several other fillers: fly ash, wollastonite powder and barite, the sum of the percentages of each component of the friction material is 100%.

[0023] A preparation method of a high temperature resistant brake lining provided by the invention comprises the following steps:

[0024] 1. Preparation of phase change materials. The magnesium oxide and aluminum oxide are mixed in a molar ratio of 1:1, and the phase change material is NaNO 3 -NaCl-Na 2 CO 3 According to a certain mass ratio (where the lowest eutectic point occurs), the mass ratio of the phase change material to the ceramic matrix is 4:6. After mixing all kinds of raw materials evenly, they w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com