Preparation method for anode support layer of solid oxide fuel cell

A technology of anode support and anode support, which is applied in the direction of solid electrolyte fuel cells, fuel cell additives, and final product manufacturing. The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

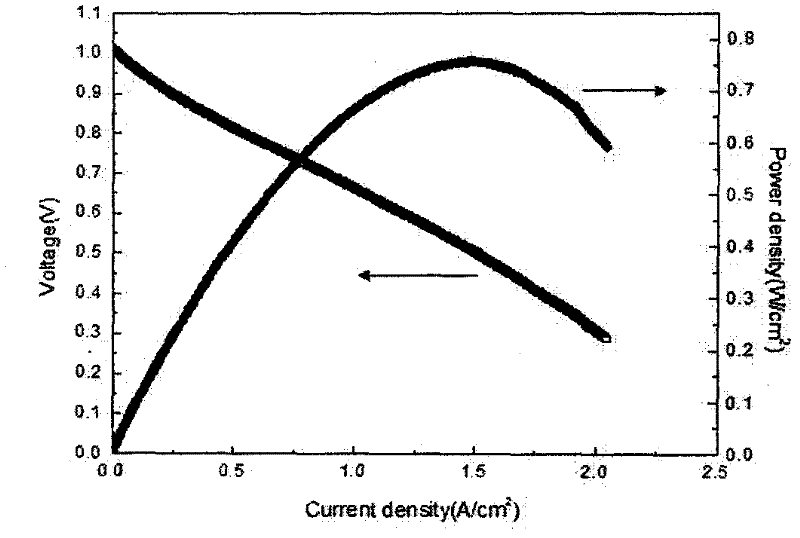

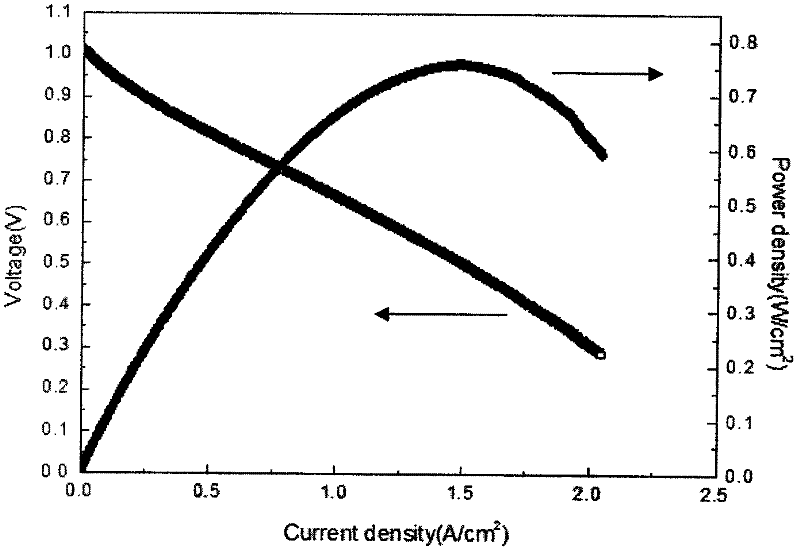

Image

Examples

Embodiment 1

[0037] Weigh 28.46g NH 4 Al(SO 4 ) 2 , add 1L of distilled water to form an aqueous solution with a concentration of 0.12mol / L, stir evenly, and use a spray gun to spray into 1.6mol / L NH3 containing 2% polyethylene glycol with a mass ratio of 2%. 4 HCO 3 In aqueous solution, NH 4 Al(OH) 2 CO 3 precipitation.

Embodiment 2

[0039] Will NH 4 Al(OH) 2 CO 3 The precipitate was repeatedly washed with distilled water and centrifuged to remove impurity ions. Finally, put the precipitate into an oven at a constant temperature of 100°C for drying. The dried sample was ground into powder in an agate mortar, and calcined in a high-temperature furnace at 1100°C to obtain ultrafine Al 2 o 3 Powder.

Embodiment 3

[0041] Accurately weigh 55gNiO, 5gMgO, 15g starch, 25g superfine Al 2 o 3 Powder, 0.3g acicular Al 2 o 3 , 2 g of polyvinylpyrrolidone and 20 g of distilled water were placed in an ultrasonic oscillator for 2 hours to disperse evenly; After hours, the obtained anode support layer slurry was placed in an oven at 90°C and dried at a constant temperature, and then taken out and ground into powder to obtain an anode support layer powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com