A Microwave-Assisted Co-immobilization Method of Aldoketone Reductase and Glucose Dehydrogenase

A technology of glucose dehydrogenase and aldehyde-ketone reductase, which is applied in the direction of immobilization on or in inorganic carriers, multi-enzyme systems, etc., can solve the problems of non-reusability, poor stability of free enzymes, etc. Effects of improved stability and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Preparation of aldehyde and ketone reductase

[0035] The nucleotide sequence shown in SEQ ID NO.1 was ligated with the vector pET28a, the ligated product was transformed into E.coli DH5α competent cells, and a single colony was picked for PCR verification to obtain positive clones, and the pET28a-Lek plasmid was obtained using a plasmid extraction kit. Then the recombinant plasmid was introduced into E.coli BL21(DE3) to obtain pET28a-Lek-E.coli BL21(DE3) strain.

[0036] The pET28a-Lek-E.coli BL21(DE3) strain was inoculated in LB liquid medium and cultivated overnight at 37°C. Transfer the bacterial solution to 1L of LB medium containing kanamycin (100 μg / mL) according to the volume concentration of 1% inoculum, culture at 37 ° C and 200 rpm until the OD600 reaches 0.6, and add IPTG to the culture solution to make it final The concentration was 0.1 mM, and the expression was induced for 12-16 hours at 25°C and 150 rpm. Centrifuge at 4°C and 8000rpm for 15mi...

Embodiment 2

[0039] Example 2 Preparation of glucose dehydrogenase

[0040] The nucleotide sequence shown in SEQ ID NO.2 was ligated with the vector pET22b, and the ligated product was transformed into E.coli DH5α competent cells, and a single colony was picked for PCR verification to obtain positive clones, and the pET22b-GDH104 plasmid was obtained using a plasmid extraction kit. Then the recombinant plasmid was introduced into E.coli BL21(DE3) to obtain pET22b-GDH104-E.coli BL21(DE3) strain.

[0041] The successfully constructed pET22b-GDH104-E.coli BL21(DE3) strain was inoculated in liquid LB medium containing ampicillin (100 μg / mL), and cultured overnight at 37° C. and 220 rpm. Take 10 mL of the bacterial liquid and transfer it to 1 L of LB medium, shake and culture at 37°C, 200rpm until the OD600 reaches 0.6, add IPTG to the culture medium to make the final concentration 0.1mM, and induce expression at 25°C, 150rpm for 12-16h. The bacterial cells were collected by centrifugation, wa...

Embodiment 3

[0044] Example 3 Making double enzymes into co-immobilized enzymes

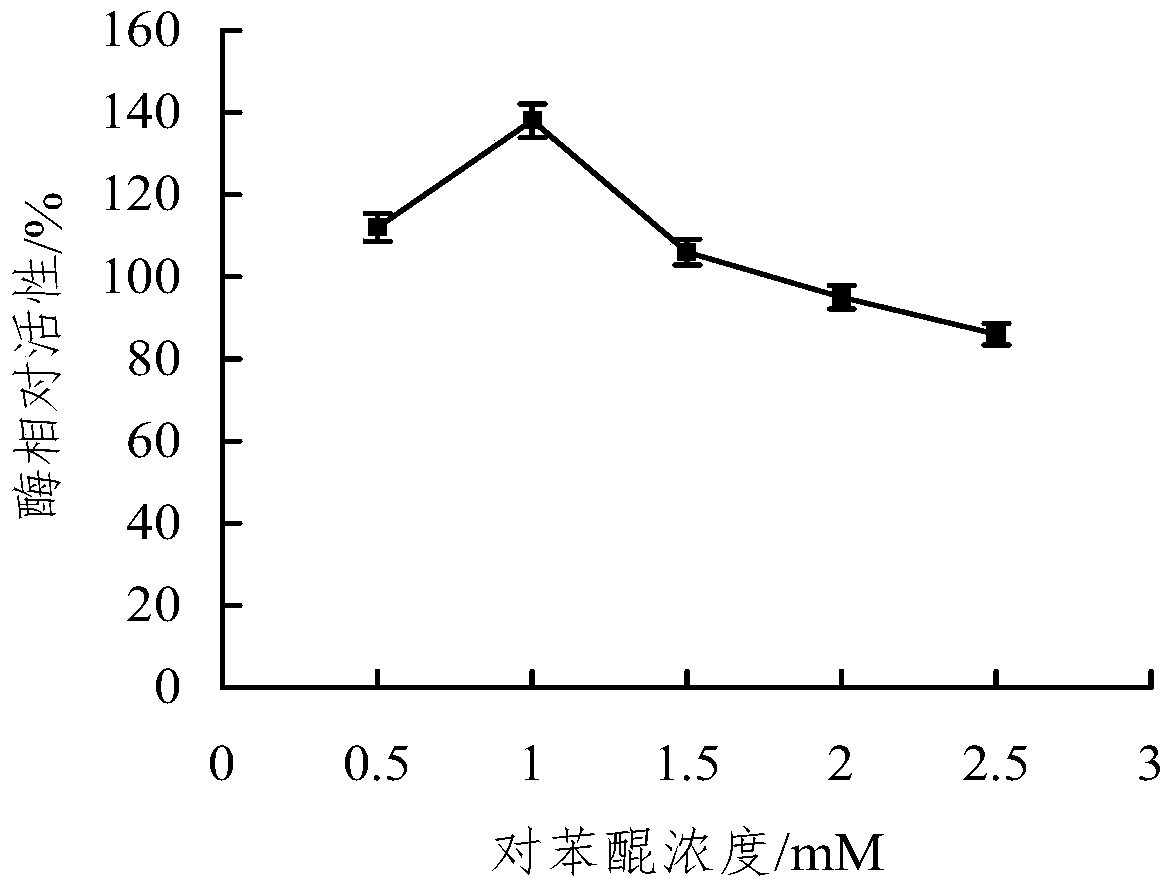

[0045] (1) Activation of the carrier: 20mgMCFs-NH 2 Dissolve the powder in 3mL of 1.0mM p-quinone solution (the solvent is 50% ethanol aqueous solution), at 25°C and 160rpm, vibrate on a constant temperature water bath shaker for 2h, centrifuge, and take the precipitate with 3mL, pH 7.0, 0.1M Wash with PBS solution, centrifuge, and redisperse the pellet in 2.42mL, pH 7.0, 0.1M PBS solution. According to the mass ratio of 100mg enzyme / g carrier, add 0.26mL of the 7.7mg / mL aldehyde and ketone reductase solution obtained in Example 1 and 0.32 mL of the 6.25mg / mL glucose dehydrogenase solution obtained in Example 2 to the mixed solution successively. mL, mix well;

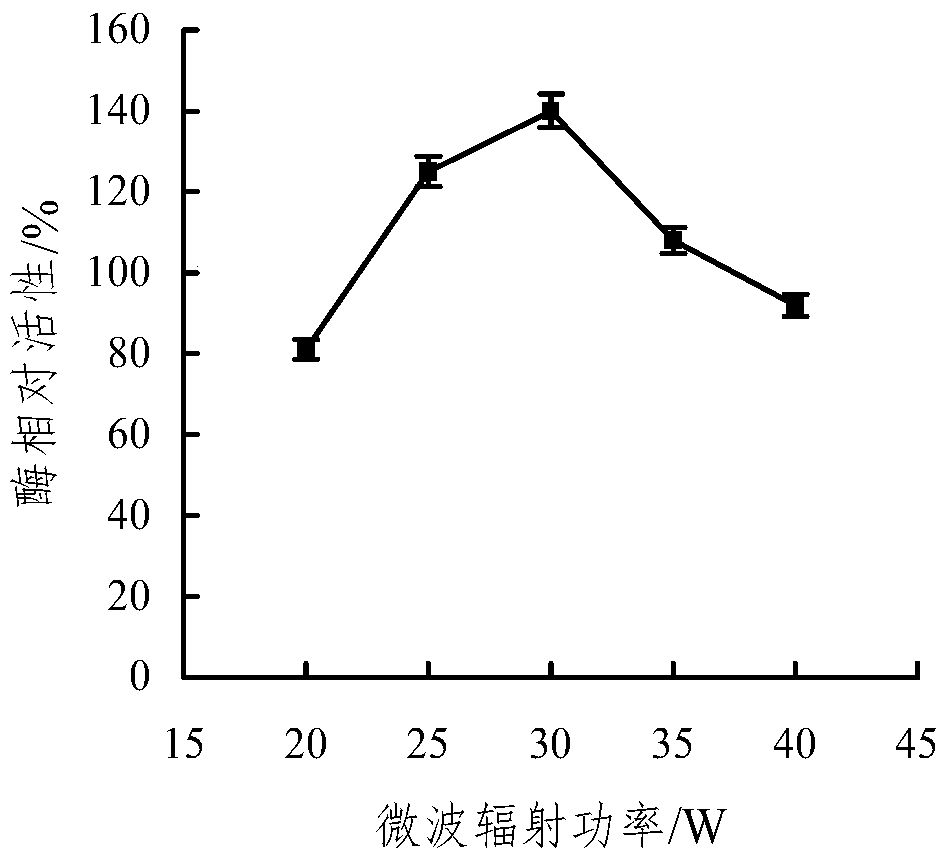

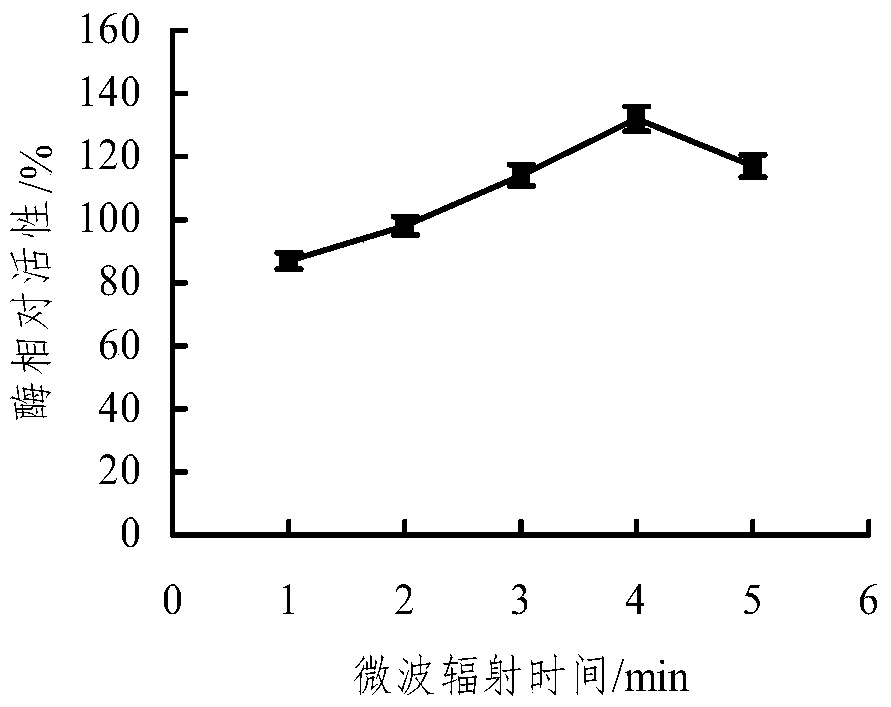

[0046] (2) Dual-enzyme co-immobilization: take the mixed solution of step (1) and irradiate it under 30W microwave conditions for 4 minutes at 0-10°C, centrifuge, and wash the precipitate with pH 7.0, 0.1M PBS solution to obtain the co-immobilized e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com