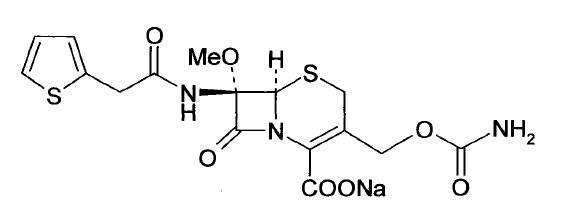

Preparation method for Cefoxintin sodium

A technology of cefoxitin sodium and cefoxitin acid, which is applied in the direction of organic chemistry, can solve the problems of low product content and high solvent residue of cefoxitin sodium, and achieve the effects of high content, good product color grade, simple and feasible method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

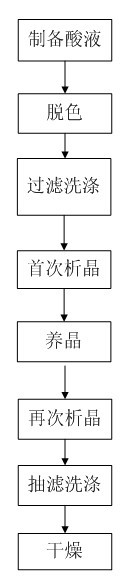

[0029] See figure 1 , A method for preparing cefoxitin sodium of the present invention, the specific steps include:

[0030] (100). Preparation of acid solution: firstly mix the first solvent and the second solvent to form a mixed solution, cool to 8°C-12°C, and then add cefoxitin acid to the mixed solution to dissolve to form an acid solution. The volume ratio of the first solvent to the second solvent is 1:5-8; the first solvent is preferably methanol, and the second solvent is preferably ketone solvents such as acetone, methyl ethyl ketone, and methyl isobutyl ketone;

[0031] (200), decolorization: control the temperature T=-2~0℃, add activated carbon to the acid solution to decolorize for 25~35min to form a decolorized acid solution;

[0032] (300). Filtration and washing: pass the decolorized acid solution through a microporous filter membrane to form a filtered acid solution, pass the lye solution through the microporous filter membrane to form a filtered lye solution, and di...

Embodiment 1

[0040] (1) Add 80ml methanol and 440ml methyl ethyl ketone into a 1000ml four-neck reaction flask, cool to 10°C, add 50g cefoxitin acid, rinse the bottle wall with 200ml methyl ethyl ketone, stir to dissolve;

[0041] (2) Control the temperature T=-2-0℃, add 5g of 767 activated carbon to decolorize for 25min;

[0042] (3) Add 85ml methanol and 10ml methyl ethyl ketone into a 500ml four-necked reaction flask, add 13.5g sodium tert-butoxide at room temperature, rinse the wall of the bottle with 15ml methanol, stir to dissolve to form lye;

[0043] (4) The lye is passed through a 0.45 micron microporous membrane. This process should take about 1 min. The temperature of the filtrate is cooled to T=-2-0℃, and it is ready for use;

[0044] (5) Prepare pickling solution, mix 50ml methanol with 250ml methyl ethyl ketone, cool to T=-2-0℃, set aside;

[0045] (6) Pass the acid solution formed in step (1) through a 0.45 micron microporous membrane, and wash the carbon cake twice with the acid solu...

Embodiment 2

[0055] (1) Add 90ml methanol and 450ml acetone into a 1000ml four-necked reaction flask, cool to 10°C, add 50g cefoxitin acid, rinse the bottle wall with 210ml acetone, stir to dissolve;

[0056] (2) Control the temperature T=-2-0℃, add 5g of 767 activated carbon to decolorize for 30min;

[0057] (3) Add 75ml methanol and 10ml acetone into a 500ml four-necked reaction flask, add 11g sodium acetate at room temperature, rinse the bottle wall with 10ml methanol, and stir to dissolve;

[0058] (4) The sodium acetate solution is passed through a 0.45 micron microporous membrane. This process should take about 1 min. The temperature of the filtrate is cooled to T=-2-0°C, and it is ready for use;

[0059] (5) Prepare pickling solution, mix 40ml methanol with 250ml acetone, cool down to T=-2-0℃, set aside;

[0060] (6) Pass the acid solution formed in step (1) through a 0.45 micron microporous membrane, and wash the carbon cake twice with the acid solution formed in step (5);

[0061] (7) Combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com