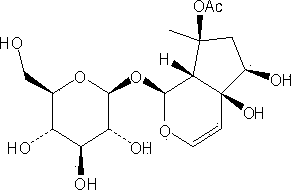

High-efficiency preparation method for acetyl harpagide reference standard product

A technology of acetyl harpatoside and reference substance, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., to achieve the effects of less solvent consumption, less environmental pollution, and less solvent toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A high-efficiency preparation method of acetylharpaside reference substance is characterized in that it is carried out according to the following process steps:

[0026] A. Extraction of raw materials: Grind 2kg of herba sinensis into coarse powder, add 20L of ethanol solution with a volume fraction of 40%, reflux extraction for 3 times, each time for 2 hours, combine the extracts, and cool to room temperature;

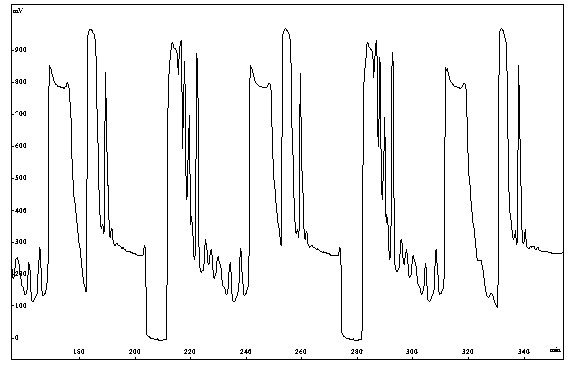

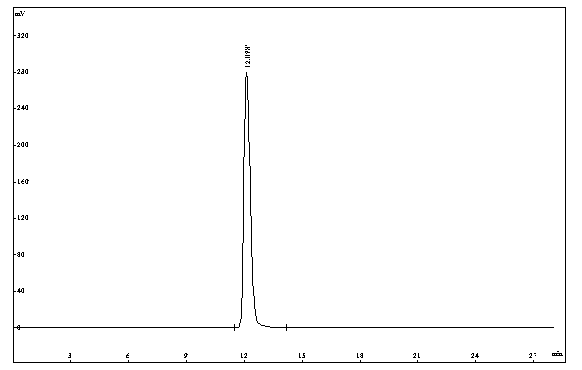

[0027] B. Macroporous resin enrichment: Weigh 1kg D101 macroporous adsorption resin, fill it with a 10cm diameter glass column to form a resin column, and the volume of the resin bed is about 3L; pass the cooled extract through the activated macropore at a speed of 3BV The adsorption resin column is used for adsorption, and then 9L of water and 6L of ethanol solution with a volume fraction of 40% are used to elute impurities, and then 6L of ethanol solution with a volume fraction of 60% is used to elute the target substance, and the eluate is collected and conce...

Embodiment 2

[0031] A high-efficiency preparation method of acetylharpaside reference substance is characterized in that it is carried out according to the following process steps:

[0032] A. Extraction of raw materials: Grind 5 kg of herba sinensis into coarse powder, add 40 L of ethanol solution with a volume fraction of 45%, reflux extraction for 3 times, each time for 2 hours, combine the extracts, and cool to room temperature;

[0033] B. Macroporous resin enrichment: Weigh 2kg AB-8 macroporous adsorption resin, fill it with a 10cm-diameter glass column to form a resin column, and the volume of the resin bed is about 6L; pass the cooled extract through the activated The macroporous adsorption resin column is adsorbed, and then 18L of water and 12L of ethanol solution with a volume fraction of 40% are used to elute impurities, and then 12L of ethanol solution with a volume fraction of 60% is used to elute the target substance, and the eluate is collected and concentrated to About 1.2L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com