Normal pressure crystallization method for monosodium glutamate

A normal pressure, crystallization technology, applied in solution crystallization, food preparation, food science, etc., can solve the problems of reducing circulating water, low carbon and energy saving, unreachable savings, small heating area, etc., to reduce equipment cost, easy to find, improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

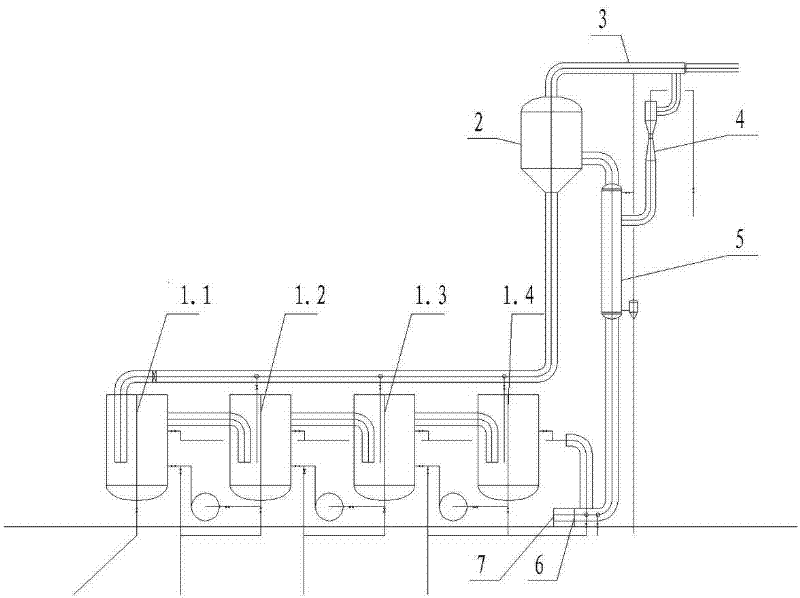

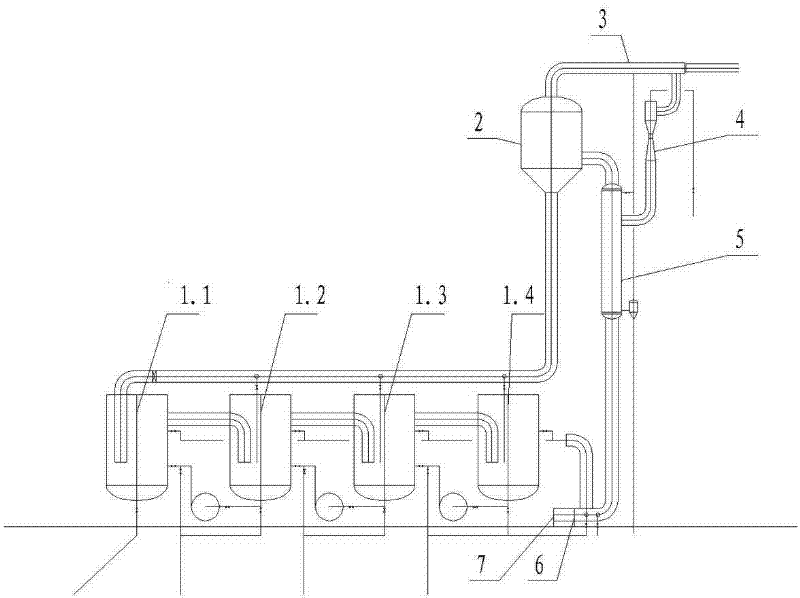

[0014] The crystallization process is completed in the normal pressure crystallization equipment, and the heating and evaporation process is completed in the negative pressure heating and evaporation equipment. The normal pressure crystallization equipment and the negative pressure heating and evaporating equipment are connected end to end by pipelines. From the normal pressure crystallization equipment to the negative pressure heating and evaporating equipment The circulation pump and feed inlet are set on the pipeline.

[0015] Said negative pressure heating evaporation equipment is that the shell and tube heat exchanger 5 as the heater and the evaporation chamber 2 are composed of pipelines connected in series, and the gas outlet of the evaporation chamber is connected to the condenser and the vacuum pump through the steam pipeline 3; The heat medium inlet of the tube heat exchanger is directly connected to the compression pump 4, and the other inlet of the compression pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com