Industrial production method of copper nanoparticle

A technology of nano-copper and particles, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of complex process, high input cost, poor stability of nano-copper particles, etc. Simple, low input cost, promotion and popularization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

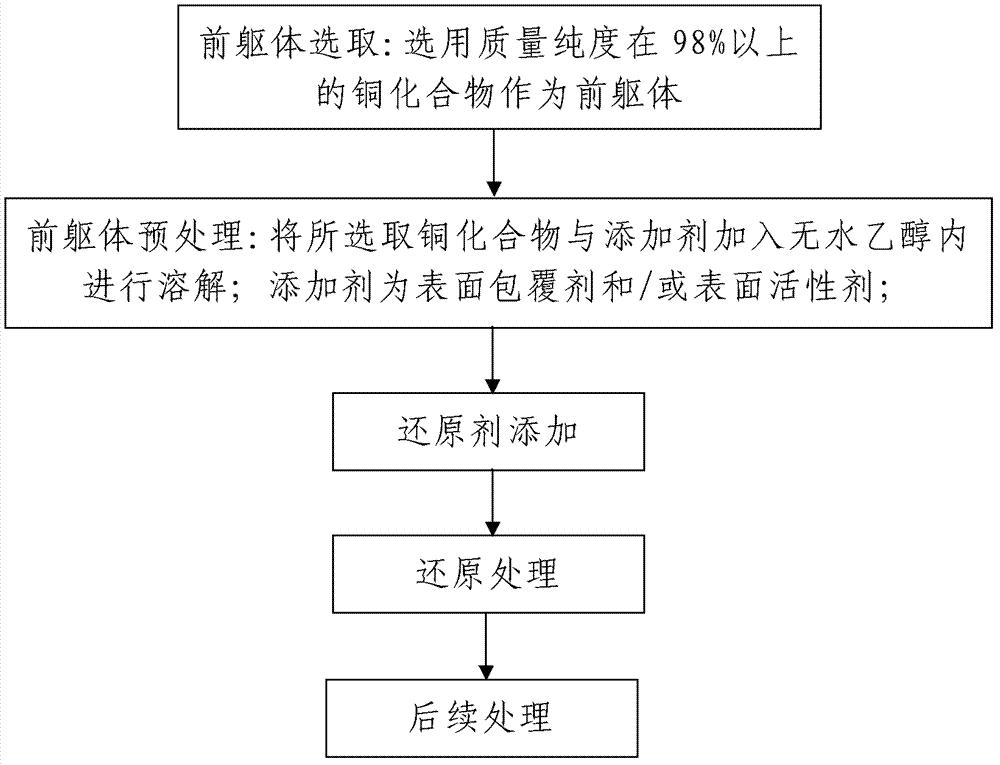

[0045] In the present embodiment, when producing nano-copper particle, comprise the following steps:

[0046] Step 1. Precursor selection: select 12.5 g of copper oxide with a mass purity above 98% as the precursor.

[0047] In actual processing, copper hydroxide or copper acetate can also be used as the precursor.

[0048] Step 2. Pretreatment of the precursor: adding the copper compound and additives selected in Step 1 into absolute ethanol (mass fraction ≥ 99.7%) for dissolution, and uniformly stirring to prepare an ethanol mixed solution.

[0049] In this embodiment, the additive is a surface coating agent, and the surface coating agent is a hydrophilic coating agent, and polyvinylpyrrolidone is selected as the hydrophilic coating agent. In actual use, first use a graduated cylinder to measure 100ml of absolute ethanol, and add 12.5g of copper oxide weighed in advance to 100ml of absolute ethanol for dissolution, and at the same time weigh 2g of polyvinylpyrrolidone (PVP)...

Embodiment 2

[0067] In this example, the difference from Example 1 is that polyether-modified silicone oil is selected as the hydrophilic coating agent in Step 2, and the rest of the production steps and process parameters are the same as in Example 1.

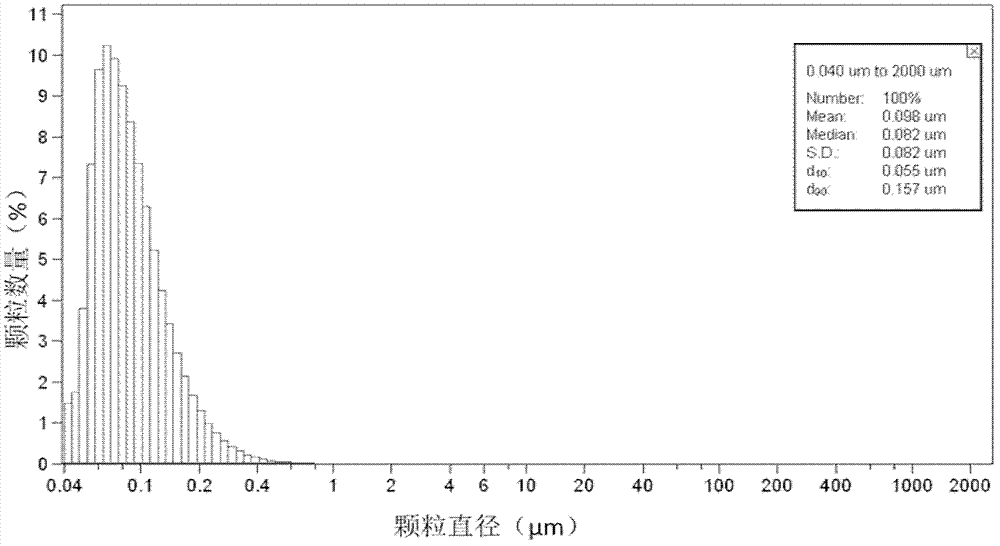

[0068] In this embodiment, polyether modified silicone oil is used as a surface coating agent to obtain copper particles with an average particle size of about 99nm. The particle size test results of the obtained copper particles are as follows: Figure 6 shown.

Embodiment 3

[0070] In this example, the difference from Example 1 is that polyacrylic acid resin is selected as the hydrophilic coating agent in step 2, and the rest of the production steps and process parameters are the same as in Example 1.

[0071] In this embodiment, polyacrylic acid resin is used as the surface coating agent to obtain copper particles with an average particle size of about 81nm. The particle size test results of the obtained copper particles are as follows: Figure 6 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com