Method for preparing one-dimensional self-assembly material with ZnO nanorod array as template

A nanorod array and self-assembly technology, applied in nanotechnology, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as film orientation and structural damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: Preparation of zinc oxide nanorod array

[0036] The ZnO nanorod array with consistent orientation was prepared by traditional hydrothermal method. The specific method is as follows:

[0037] 1. Prepare 15ml each of 0.1M zinc nitrate and 0.1M hexamethylenetetramine solutions, and set aside;

[0038] 2. Add zinc nitrate and hexamethylenetetramine into a 50ml polytetrafluoroethylene hydrothermal kettle, and insert a cleaned substrate such as ITO glass or cordierite into the reaction solution at an angle of 45 degrees, and 95°C water Thermal reaction 4h.

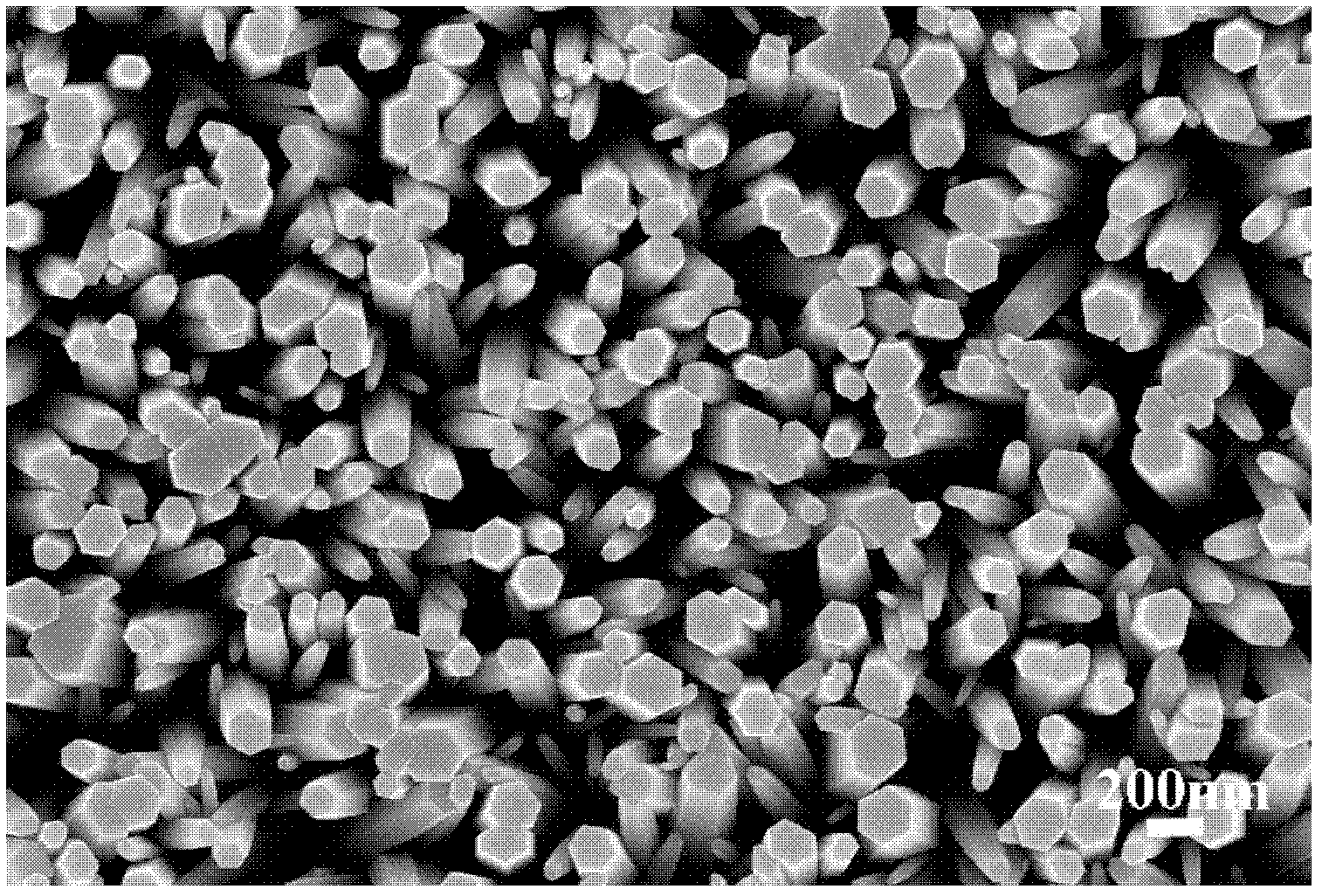

[0039] 3. The scanning electron microscope photos of the prepared ZnO nanorod arrays are shown in figure 1 , as shown in the figure, the ZnO nanorods have a hexagonal columnar structure with a uniform growth orientation and an average diameter of 200 nm.

Embodiment 2

[0040] Example 2: Cerium Oxide Nanotube Arrays

[0041] 1. Preparation method: Immerse the zinc oxide nanorod array prepared in Example 1 into a 0.1M cerium nitrate solution, and conduct a hydrothermal reaction at a constant temperature of 95°C for 2 hours to obtain a cerium oxide nanorod with similar size and density as the zinc oxide nanorod array. tube array.

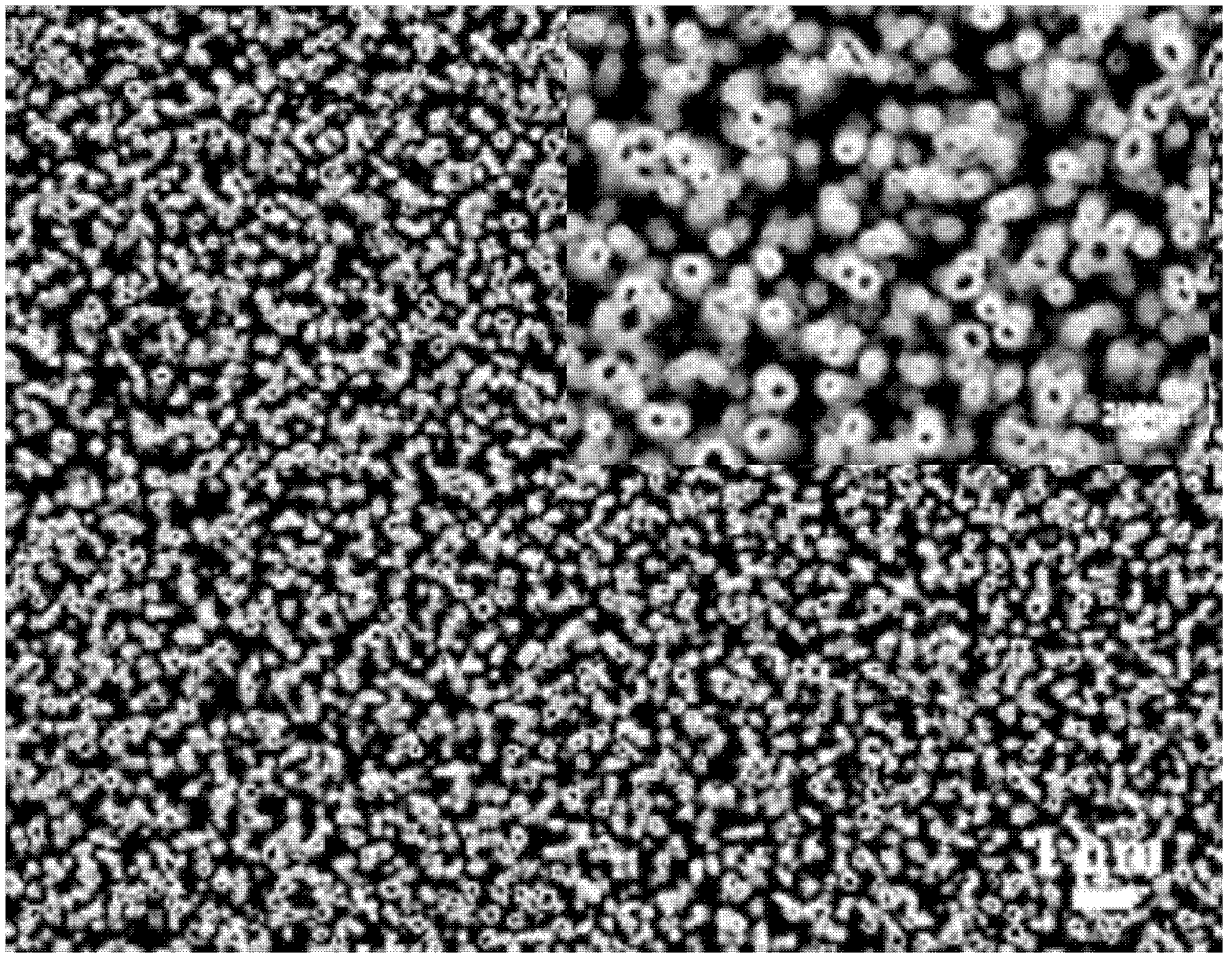

[0042] 2. The obtained cerium oxide: the scanning electron microscope photo of the prepared cerium oxide nanotube array is shown in figure 2 , as shown, the cerium oxide tubular structures have similar orientation and density to the ZnO nanorod arrays.

Embodiment 3

[0043] Embodiment 3: cobalt oxide nanotube array

[0044]1. Preparation method: immerse the zinc oxide nanorod array synthesized in Example 1 into a 0.16M cobalt nitrate solution, and conduct a hydrothermal reaction at 95° C. for 3 hours to obtain the cobalt oxide nanotube array.

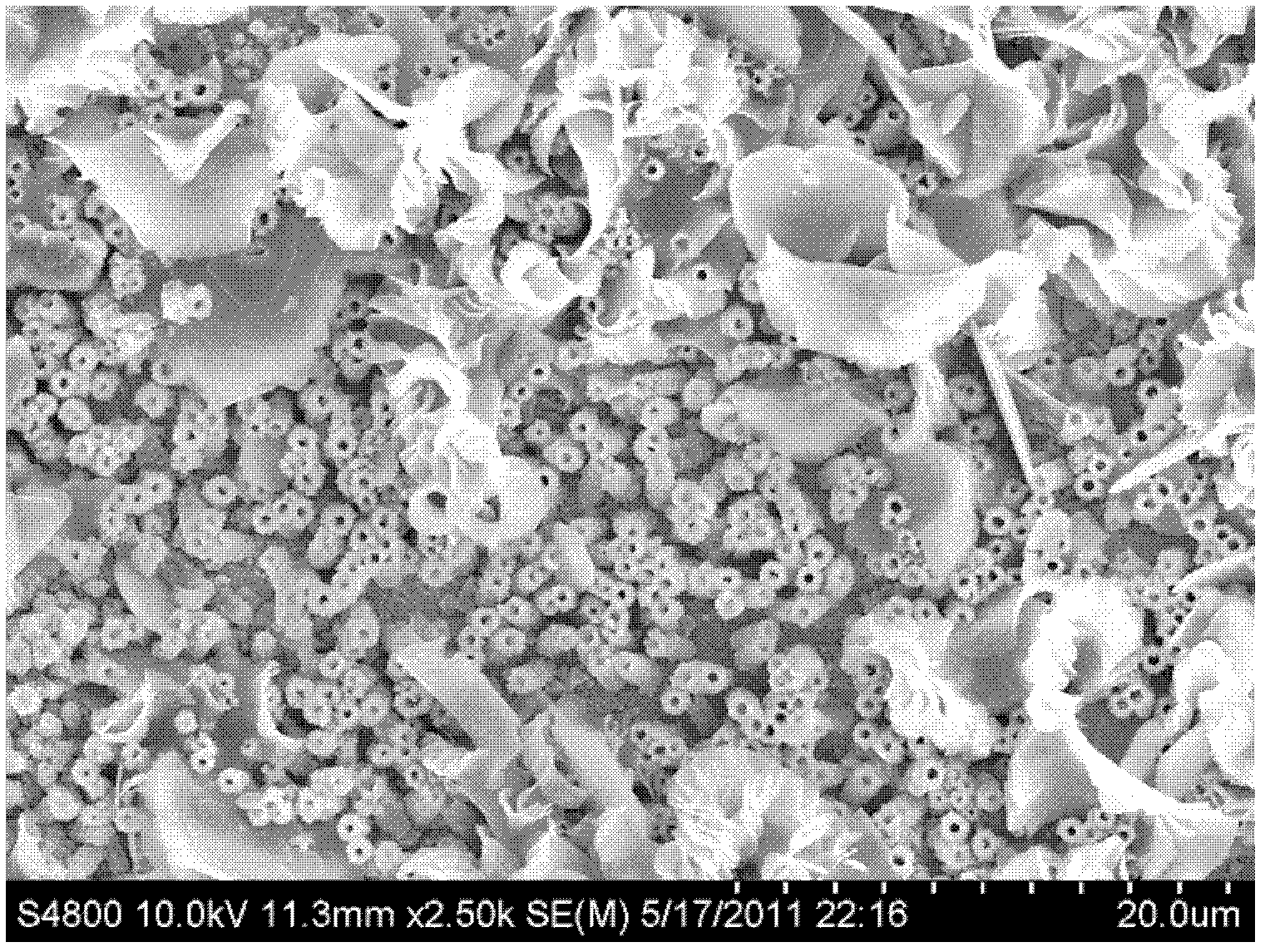

[0045] 2. Obtained cobalt oxide: the scanning electron microscope photo of the prepared cobalt oxide nanotube array is shown in image 3 , image 3 As shown, the substrate is evenly distributed with a tubular array structure of cobalt oxide with uniform orientation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com