Design and preparation of iodine antibacterial hydroxyapatite coating titanium and titanium alloy implants

A technology of hydroxyapatite and titanium alloy, applied in the field of medical biomaterial preparation, can solve the problems of restricting clinical research and use, increasing production cost and production cycle, poor physical and chemical properties of coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] 1. Surface pretreatment of plants in titanium and titanium alloy substrates: cleaning and sandblasting pretreatment.

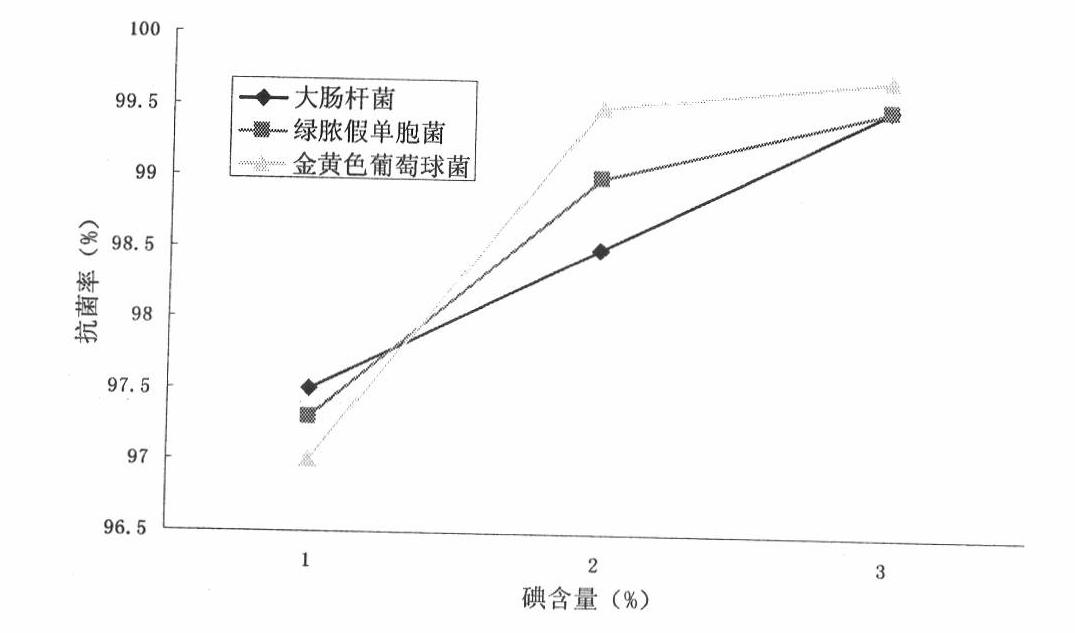

[0016] 2. Preparation of hydroxyapatite and povidone-iodine mixed powder Weigh hydroxyapatite powder and povidone-iodine powder according to a certain ratio, and ball mill and dry mix for 2 hours to prepare mixed powder with iodine content of 1-3 wt%.

[0017] 3. Using a vacuum plasma spraying process, the mixed powder is deposited on the titanium and titanium alloy metal substrates according to the following parameters (Table 1).

[0018] Table 1 Spraying parameters

[0019]

[0020]

[0021] slpm: standard liters per minute

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com