Energy-efficient vehicle gear lubricating oil composition

A technology of gear lubricating oil and composition, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of inconspicuous energy-saving effect, achieve excellent energy-saving and friction-reducing performance, improve gear transmission efficiency, and facilitate deployment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

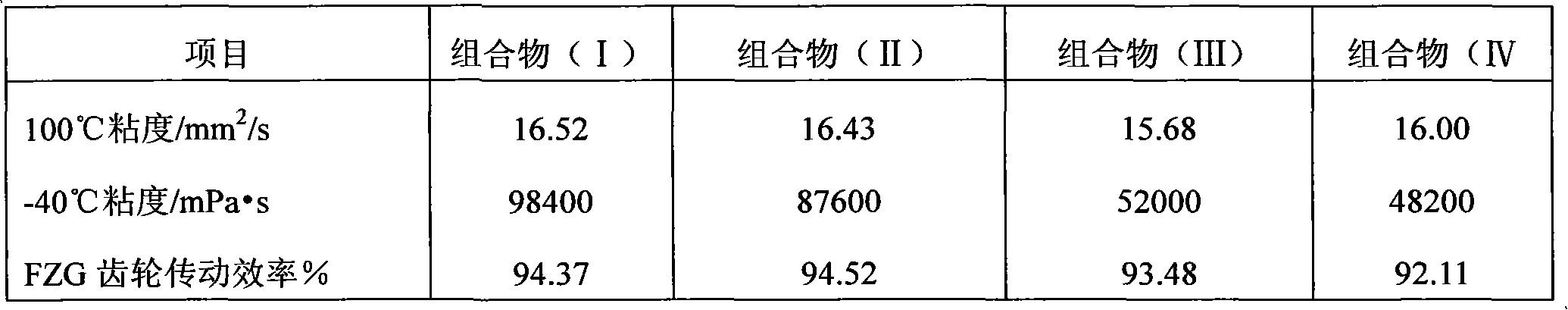

Embodiment 1

[0025] Lubricating oil composition (I), it comprises: No. 5 oil (component A) of Daqing hydroisomerization dewaxed base oil of 70.5wt%; The polymethacrylate (component B) of 20.0wt%; 0.5wt% % polyalpha-olefin (component C); 4.5 wt% of sulfurized isobutylene (component D); 1.0 wt% of acid lauryl phosphite (component E); 1.0 wt% of dialkyl disulfide Zinc phosphate (component F); 1.0 wt% boronated succinimide (component G); 1.5 wt% boronated glyceryl oleate (component H). Lubricating oil composition (II) except that 70.5wt% of Daqing hydroisomerization dewaxed base oil No. 5 oil in component (A) is replaced by 70.5wt% poly-a-olefin synthetic oil PAO-4, the rest are the same combination Object (I). Lubricating oil composition (III) is the same as composition (I) except that 70.5wt% of Daqing hydroisomerized dewaxed base oil No. 5 oil in component (A) is replaced by 70.5wt% diester synthetic oil. Lubricating oil composition (IV) is the same as composition (I) except that 70.5wt% ...

Embodiment 2

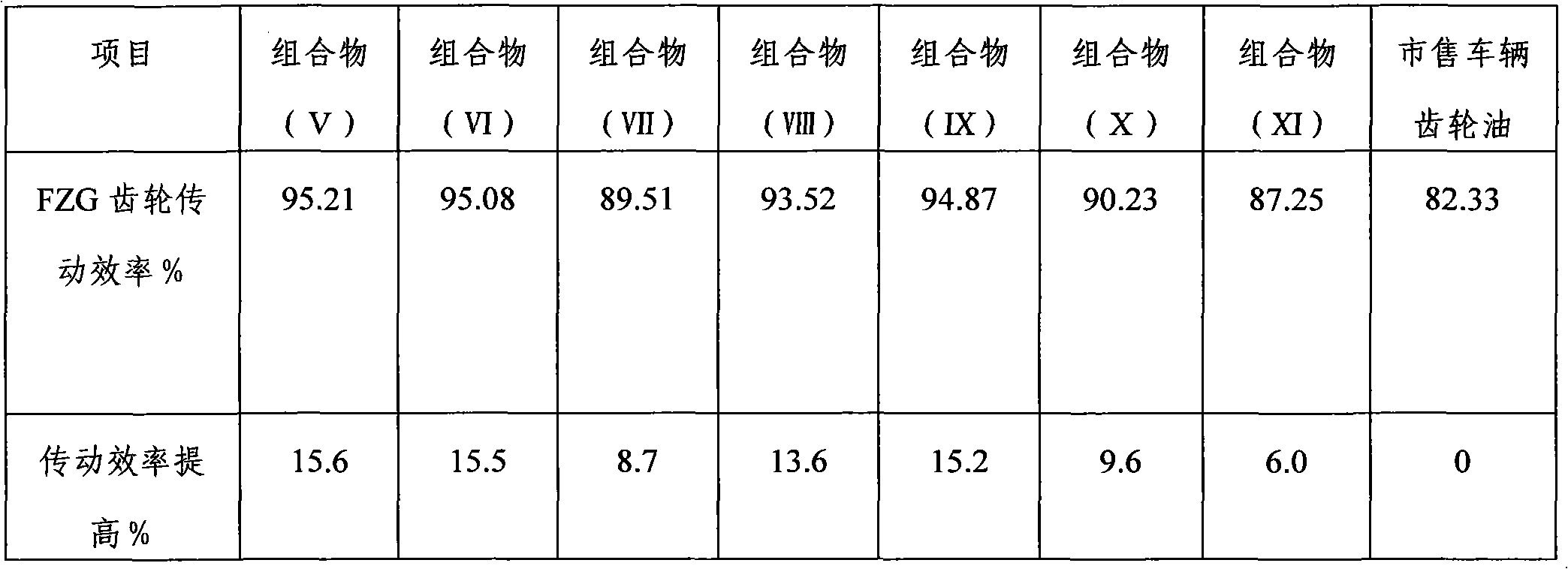

[0030]Lubricating oil composition (V), it comprises: 85.0wt% Daqing hydroisomerization dewaxed base oil No. 5 oil (component A); 8.0wt% polyisobutylene (component B); 1.5wt% polyformaldehyde 4.0 wt% of tert-butyl trisulfide (component D); 0.8 wt% of isooctyl m-diphosphonate (component E); 0.1 wt% of benzotriazepam Azole (component F); 0.1 wt% dihydroxyethylamide oleate (component G); 0.5 wt% borated ethylene glycol oleate (component H). Lubricating oil composition (VI) is the same as composition (V) except that 0.5wt% borated oleic acid ethylene glycol ester of component (H) is replaced by 0.5wt% high alkali value alkyl salicylate . The lubricating oil composition (VII) is the same as the composition (V) except that 0.5wt% of the borated oleic acid ethylene glycol ester in the component (H) is replaced by 0.5wt% of the high alkali value sulfurized alkylphenate. Lubricating oil composition (VIII) is the same as composition (V) except that 0.5wt% of borated oleic acid ethylene...

Embodiment 3

[0035] Additive composition (XII), it comprises: the polyalpha-olefin synthetic oil PAO4 (component A) of 72.8wt%; The polymethacrylate (component B) of 20.0wt%; 0.1wt% polyalpha-olefin ( Component C); 3.5% by weight of sulfurized isobutylene (component D); 0.7% by weight of dialkyl trithiophosphate and 0.7% acidic phosphate stearylamine salt (component E); 0.2% by weight of benzene Paratriazole (component F); 0.5 wt% boronated succinimide (component G); 1.5 wt% boronated olein (component H). The evaluation results of composition (XII) are listed in Table 3.

[0036] Table 3 Composition (XII) Evaluation Results

[0037]

[0038] The experimental results show that the lubricating oil composition (XII) not only passed the four gear racks of L-42, L-37, L-33, and L-60, but also reached the specification index of GB 13895-92 (API GL-5), Moreover, it has also passed the adaptability test with sealing materials, FZG gear machine test, L-60-1 bench, Mack cycle bench and car manu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com